South Africa Top pellet machine, animal feed pellet machine Manufacturer

MAIKONG: Leading Biofuel Equipment Manufacturer

Based in SZ, GD province, MAIKONG has established itself as a premier manufacturer of biomass processing equipment. With access to China’s most advanced supply chains and manufacturing facilities, we produce high-quality, cost-effective biofuel pellet machines that meet international standards.

Our Manufacturing Advantage

- State-of-the-art production facilities in SZ, GD

- Advanced CNC machining and precision engineering

- Rigorous quality control at every production stage

- ISO-certified manufacturing processes

- Experienced technical team with 15+ years in biomass equipment design

Customer-Focused Approach

- Customized machine configurations for specific needs

- Comprehensive technical documentation and support

- 24/7 WhatsApp technical assistance

- Detailed biomass pellet machine design drawings provided

- Competitive biomass pellet machine prices for South African market

Ready to Explore MAIKONG Biofuel Solutions?

Our technical team is available to discuss your specific biomass processing requirements and recommend the ideal equipment configuration.

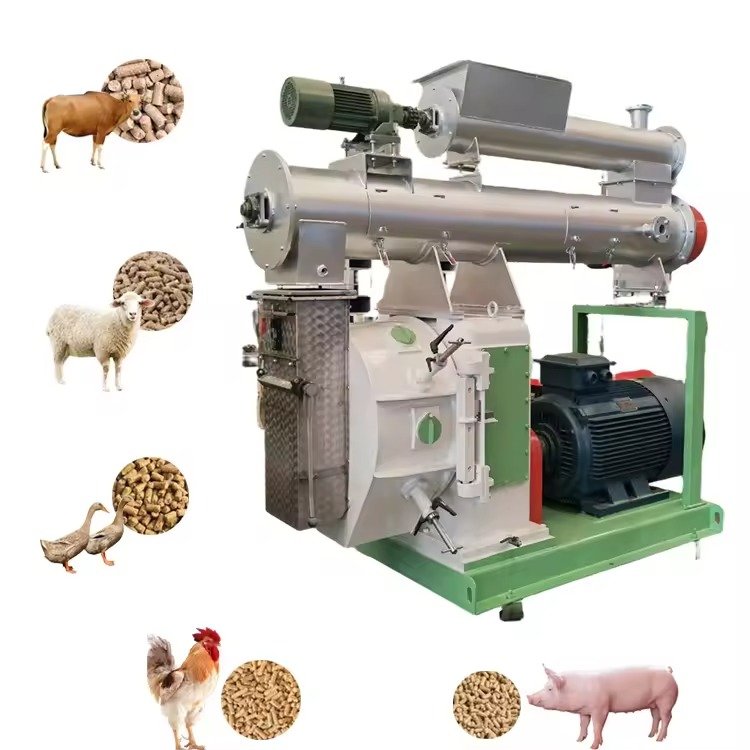

Comprehensive Biofuel Pellet Machine Range

MAIKONG offers a diverse range of biofuel pellet machines to meet various production requirements. From small-scale operations to industrial-level production, our equipment delivers consistent performance and excellent return on investment.

Our Flagship Biofuel Pellet Machine Models

| Model | Production Capacity | Power | Die Diameter | Applicable Materials | Pellet Size |

| MK-460P | 600-800 kg/h | 45 kW | 460 mm | Wood, sawdust, agricultural waste | 6-8 mm |

| MK-560P | 1500-2000 kg/h | 132 kW | 560 mm | Wood, sawdust, straw, rice husk | 6-10 mm |

| MK-700P | 2000-2500 kg/h | 160 kW | 700 mm | All biomass materials | 6-12 mm |

| MK-850P | 2500-4000 kg/h | 220 kW | 850 mm | Industrial-scale biomass processing | 6-12 mm |

Machine Types by Configuration

Vertical Ring Die Pellet Machines

Our vertical ring die configuration offers maximum efficiency for continuous operation. Ideal for industrial-scale biomass processing with output ranging from 800 kg/h to 4000 kg/h.

High Efficiency

Industrial Grade

Horizontal Ring Die Pellet Machines

Horizontal configuration provides excellent performance for medium-scale operations. Production capacity ranges from 500 kg/h to 4000 kg/h with optimized energy consumption.

Energy Efficient

Medium Scale

Flat Die Pellet Machines

Compact and affordable solution for small-scale operations. Available in electric, diesel, and PTO-driven configurations with capacities from 100 kg/h to 900 kg/h.

Cost-Effective

Versatile

Find Your Ideal Biofuel Pellet Machine

Not sure which model best suits your operation? Our technical consultants can help you select the perfect configuration based on your production requirements and available raw materials.

Advanced Technical Features of MAIKONG Biofuel Pellet Machines

Core Components

- Premium Ring Die: Double-layer stainless steel construction with optimized hole pattern for maximum throughput and durability

- High-Performance Rollers: Precision-engineered with wear-resistant alloy steel, extending service life by 5-7 times compared to standard rollers

- Industrial Gearbox: Heavy-duty design for stable transmission, low noise operation, and excellent load capacity

- Premium Motors: Energy-efficient motors with 3-year warranty and CE certification

- Automatic Lubrication System: Ensures continuous operation with minimal maintenance requirements

Operational Advantages

- Intelligent Control System: PLC-based operation with touchscreen interface for precise production management

- Adaptive Feed System: Automatically adjusts to different biomass materials for consistent pellet quality

- Cooling System: Integrated oil cooling for extended continuous operation

- Safety Features: Emergency stop, overload protection, and automatic shutdown systems

- Low Maintenance Design: Easy access to wear parts and simplified maintenance procedures

Material Processing Capabilities

Our biomass pellet machines are designed to process a wide range of raw materials, making them ideal for South Africa’s diverse agricultural and forestry sectors:

Wood-Based Materials

- Sawdust

- Wood chips

- Bark

- Forestry residues

- Wood processing waste

Agricultural Residues

- Corn stalks

- Rice husks

- Wheat straw

- Sugarcane bagasse

- Cotton stalks

Other Biomass

- Palm kernel shells

- Coconut shells

- Olive pomace

- Sunflower husks

- Coffee grounds

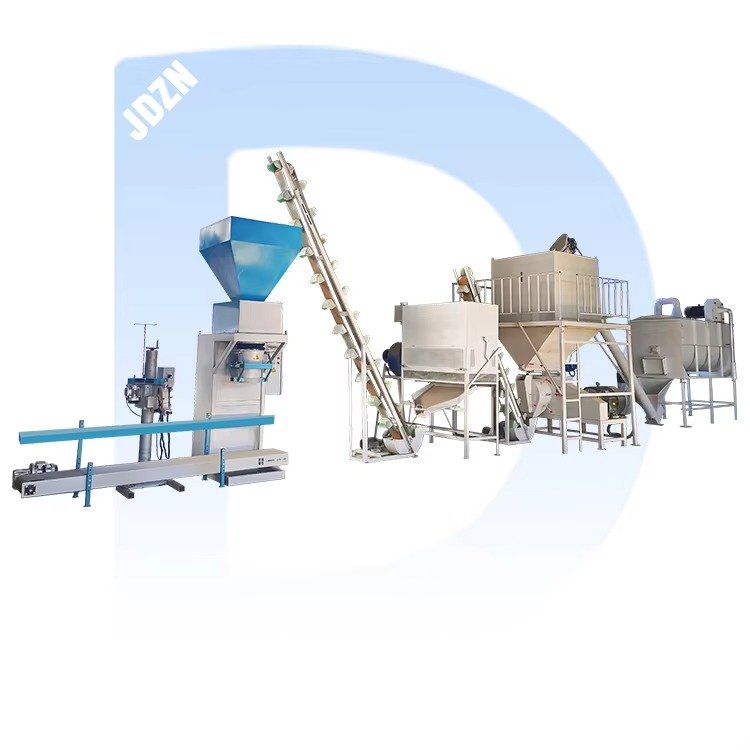

Complete Biomass Pellet Production Lines

Beyond individual machines, MAIKONG provides complete turnkey biomass pellet production lines tailored to your specific requirements. Our integrated solutions ensure seamless operation from raw material processing to final pellet packaging.

Production Line Components

Pre-Processing Equipment

- Wood chippers

- Hammer mills

- Crushers

- Screening systems

Core Processing Equipment

- Drying systems

- Pellet mills

- Cooling systems

- Quality control equipment

Post-Processing Equipment

- Pellet coolers

- Screening machines

- Packaging systems

- Storage solutions

Production Line Capacities

| Production Scale | Capacity (tons/hour) | Recommended Models | Space Requirement | Ideal For |

| Small | 0.5-1 | MK-460P | 300-500m² | Small businesses, farms, local supply |

| Medium | 1-3 | MK-560P | 500-1000m² | Regional suppliers, medium enterprises |

| Large | 3-5 | MK-700P | 1000-2000m² | Industrial suppliers, export operations |

| Industrial | 5+ | MK-850P (multiple units) | 2000m²+ | Large-scale industrial production, major exporters |

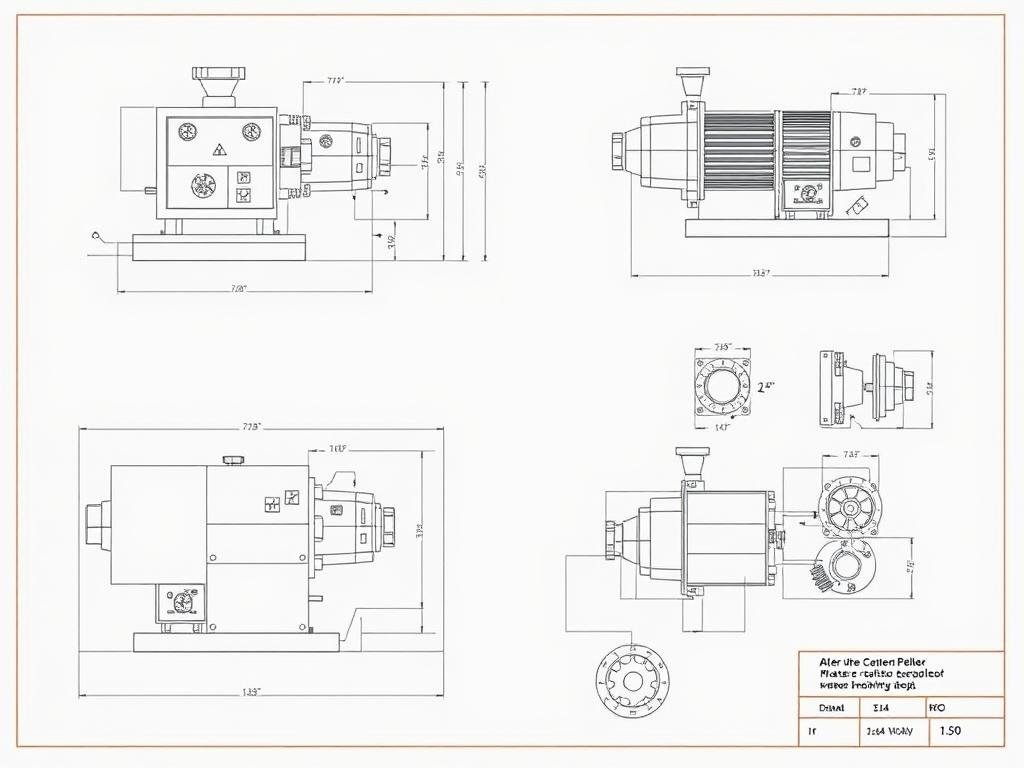

Design Your Custom Pellet Production Line

MAIKONG offers complete project planning, from initial concept to installation and commissioning. Our engineers will create detailed biomass pellet machine design drawings tailored to your specific requirements.

Biomass Pellet Machine Price Considerations

Understanding the factors that influence biomass pellet machine prices can help you make an informed investment decision. MAIKONG offers competitive pricing while maintaining exceptional quality standards.

Key Price Factors

Machine Specifications

- Production Capacity: Higher output machines require more robust components and larger motors

- Die Material: Stainless steel dies offer longer service life but at a higher initial cost

- Motor Quality: Premium motors with higher efficiency ratings affect overall price

- Control Systems: Advanced automation and monitoring systems add to the base price

Additional Considerations

- Customization Requirements: Specific adaptations for unique materials or conditions

- Auxiliary Equipment: Pre-processing and post-processing equipment needs

- Installation Support: Technical assistance during setup and commissioning

- Warranty and Service Packages: Extended coverage options for peace of mind

MAIKONG Pricing Advantage

As a direct manufacturer with optimized supply chains in GD province, MAIKONG offers significant pricing advantages compared to European or American equipment with similar specifications:

MAIKONG Value Proposition

- 30-40% lower initial investment compared to Western equipment

- Direct factory pricing without intermediary markups

- Competitive shipping rates to South African ports

- Excellent spare parts availability at reasonable prices

- Flexible payment terms for qualified businesses

Investment Considerations

- Consider total cost of ownership, not just initial price

- Factor in installation and commissioning costs

- Account for operator training requirements

- Plan for regular maintenance and wear parts replacement

- Calculate ROI based on local biomass availability and market prices

For specific biomass pellet machine price quotes tailored to your requirements, contact our sales team with details about your production needs, available raw materials, and desired output capacity.

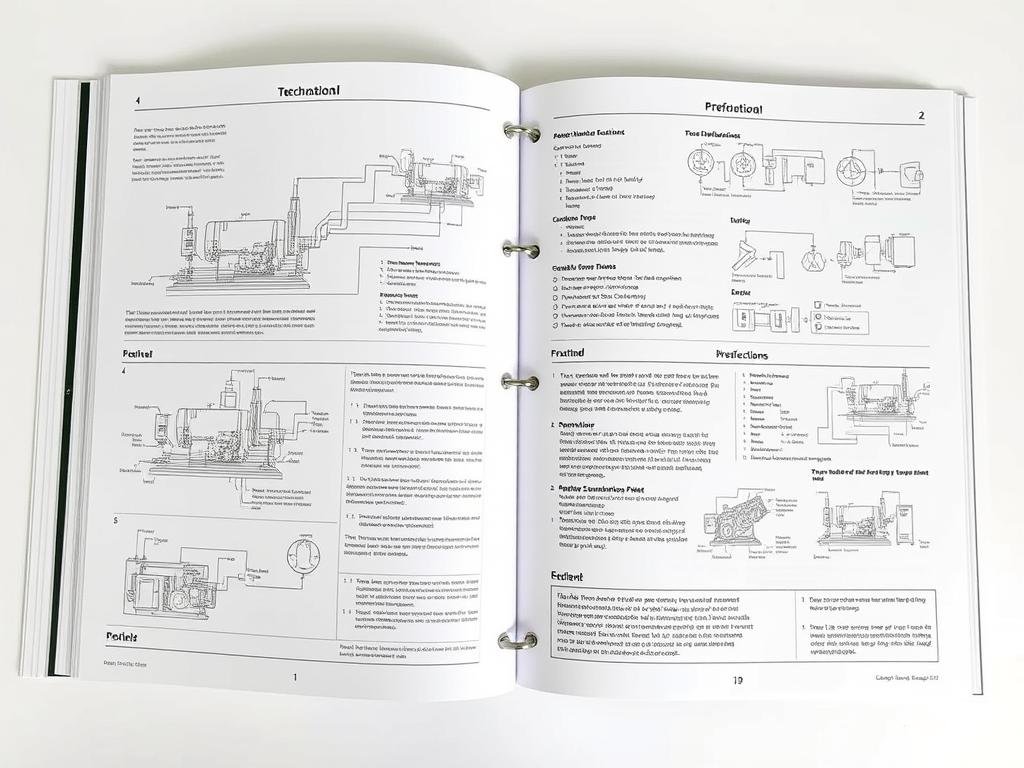

Comprehensive Technical Support and Documentation

MAIKONG provides extensive technical support and documentation to ensure your biofuel pellet machine operates at peak efficiency. Our commitment to customer success extends from initial consultation through the entire lifecycle of your equipment.

Technical Documentation

Every MAIKONG biomass pellet machine comes with comprehensive documentation, including:

Detailed Machine Manuals

- Installation guidelines

- Operation procedures

- Maintenance schedules

- Troubleshooting guides

Technical Drawings

- Detailed machine schematics

- Component diagrams

- Installation layouts

- Electrical wiring diagrams

Process Documentation

- Process flow diagrams

- Material handling guidelines

- Quality control procedures

- Production optimization tips

Ongoing Technical Support

Remote Support Services

- 24/7 WhatsApp Technical Assistance: Immediate response to operational questions

- Video Troubleshooting: Visual guidance for maintenance and repairs

- Remote Diagnostics: For machines equipped with IoT capabilities

- Software Updates: Latest control system improvements

On-Site Support Options

- Installation Supervision: Expert guidance during setup

- Commissioning Assistance: Ensuring optimal initial operation

- Operator Training: Hands-on instruction for your team

- Preventive Maintenance: Scheduled service visits

Need Technical Support?

Our technical team is available to answer your questions about biofuel pellet machines, provide biomass pellet machine design drawings, or assist with troubleshooting.

Biofuel Pellet Machines for the South African Market

South Africa’s growing focus on renewable energy makes it an ideal market for biomass pellet production. MAIKONG’s biofuel pellet machines are specifically adapted to meet the unique requirements of South African businesses.

South African Market Advantages

Resource Utilization

- Convert abundant agricultural waste into valuable fuel

- Process forestry residues from South Africa’s timber industry

- Utilize invasive plant species as feedstock

- Create value from sugar industry bagasse

Business Opportunities

- Supply growing domestic market for renewable heating fuel

- Export high-quality biomass pellets to European markets

- Provide fuel for industrial boilers transitioning from coal

- Support South Africa’s renewable energy initiatives

Adaptations for South African Conditions

MAIKONG biofuel pellet machines include specific features to address South African operational challenges:

Climate Considerations

- Enhanced cooling systems for hot climate operation

- Dust management for dry conditions

- Moisture control for varying humidity levels

- Weather-resistant electrical components

Power Supply Adaptations

- Voltage stabilization for inconsistent power supply

- Generator compatibility for backup power

- Soft-start systems to reduce peak load demands

- Power-efficient components to reduce electricity costs

Local Material Processing

- Customized dies for local biomass types

- Adjustable settings for varying material densities

- Enhanced pre-processing for fibrous materials

- Specialized wear parts for abrasive feedstocks

Start Your Biomass Pellet Business in South Africa

MAIKONG provides complete business solutions including equipment, technical support, and market guidance for South African entrepreneurs entering the biomass pellet industry.

Why Choose MAIKONG for Your Biofuel Pellet Machine Needs

Quality Assurance

Every MAIKONG biomass pellet machine undergoes rigorous testing before shipment, ensuring reliable performance from day one.

Competitive Pricing

Direct manufacturer pricing and optimized production processes allow us to offer competitive biomass pellet machine prices without compromising quality.

Comprehensive Support

From initial consultation to ongoing operation, MAIKONG provides responsive technical support and detailed biomass pellet machine design drawings.

MAIKONG is committed to advancing sustainable energy solutions in South Africa through high-quality biofuel pellet machines and complete biomass processing systems. Our equipment combines Chinese manufacturing efficiency with international quality standards, providing South African businesses with reliable, cost-effective solutions for biomass pellet production.

Ready to Transform Biomass into Profit?

Contact MAIKONG today to discuss your specific requirements and discover how our biofuel pellet machines can help you capitalize on South Africa’s growing renewable energy market.