In today’s competitive poultry industry, efficient feed production is the cornerstone of profitable operations. MAIKONG’s advanced chicken feed machines are specifically designed to meet the unique demands of South African poultry farms and feed mills. Our high-performance equipment transforms raw materials into nutritionally balanced feed pellets, significantly reducing production costs while improving feed conversion ratios for your poultry business.

MAIKONG: Leading Manufacturer of Chicken Feed Pellet Machines

Based in SZ, GD, MAIKONG has established itself as a premier manufacturer of high-quality chicken feed pellet machines and complete feed production lines. With our advanced manufacturing facilities and robust supply chain network across China, we deliver superior equipment that combines cutting-edge technology with exceptional durability.

Our commitment to innovation has positioned us as industry leaders in developing efficient, reliable, and cost-effective chicken pellet making machines that meet the specific requirements of South African poultry operations. Whether you’re running a small farm or a large commercial feed mill, our equipment is designed to optimize your feed production process.

Need Technical Assistance?

Our engineers are available to answer your questions about our chicken feed machines and help you select the right model for your operation.

WhatsApp Technical Support

Why Choose MAIKONG Chicken Feed Making Machines

Superior Feed Quality

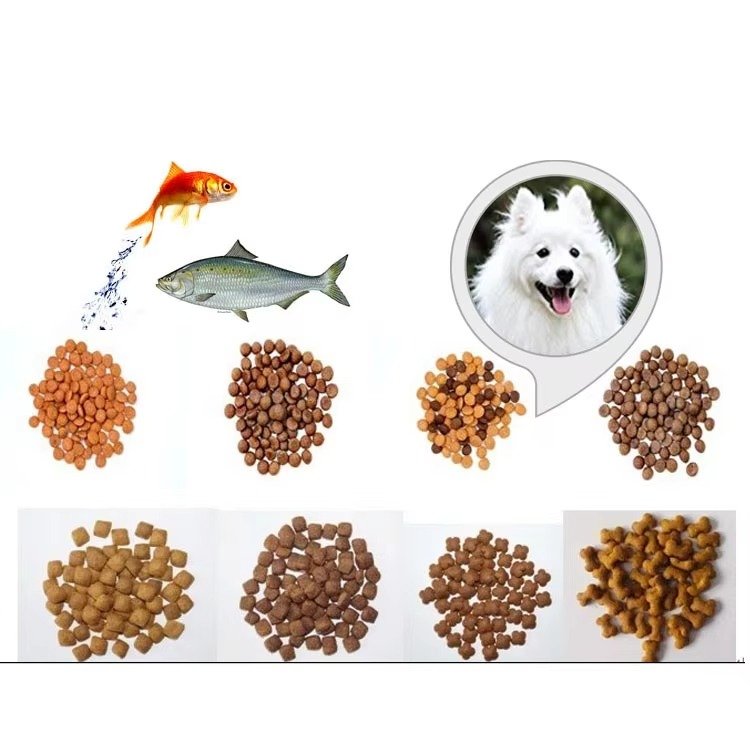

Our chicken feed pellet machines produce uniform, high-density pellets that reduce waste, improve digestibility, and enhance nutrient absorption. The consistent pellet size and quality ensure better feed conversion ratios (FCR) for your poultry, leading to healthier birds and increased productivity.

Operational Efficiency

MAIKONG chicken feed making machines are engineered for maximum efficiency, with advanced gear transmission systems that ensure smooth operation while consuming less power. Our machines deliver higher output with lower energy costs, making them an economical choice for South African poultry operations.

Exceptional Durability

Built with premium materials and precision engineering, our chicken feed making pellet machines are designed to withstand continuous operation in demanding environments. The high-quality components, including stainless steel conditioners and wear-resistant dies, ensure extended service life and reduced maintenance costs.

Customizable Solutions

We understand that every poultry operation has unique requirements. That’s why we offer customizable chicken feed machine configurations to match your specific production needs, space constraints, and budget considerations. From small-scale operations to large commercial feed mills, we have the perfect solution.

Technical Specifications of MAIKONG Chicken Feed Pellet Machines

Our comprehensive range of chicken feed pellet machines includes models suitable for various production capacities. Each machine is built with precision engineering and premium components to ensure optimal performance and longevity.

| Model |

Output (t/h) |

Main Motor Power (kw) |

Ring Die Diameter (mm) |

Feeder Power (kw) |

Conditioner Power (kw) |

| MK-SZLH250 |

1~1.5 |

22 |

250 |

1.1 |

1.5 |

| MK-SZLH320 |

3~4 |

37 |

320 |

1.5 |

2.2 |

| MK-SZLH350 |

5~6 |

55 |

350 |

1.5 |

3 |

| MK-SZLH420 |

10~12 |

110 |

420 |

1.5 |

7.5 |

| MK-SZLH508 |

15~16 |

160 |

508 |

2.2 |

11 |

| MK-SZLH558 |

20~22 |

185 |

558 |

2.2 |

11 |

| MK-SZLH678 |

30~33 |

250 |

673 |

2.2 |

11 |

| MK-SZLH768 |

38~40 |

315 |

762 |

2.2 |

11 |

Not Sure Which Model Is Right For You?

Our technical team can help you select the perfect chicken feed machine based on your production requirements and budget.

Email For Expert Advice

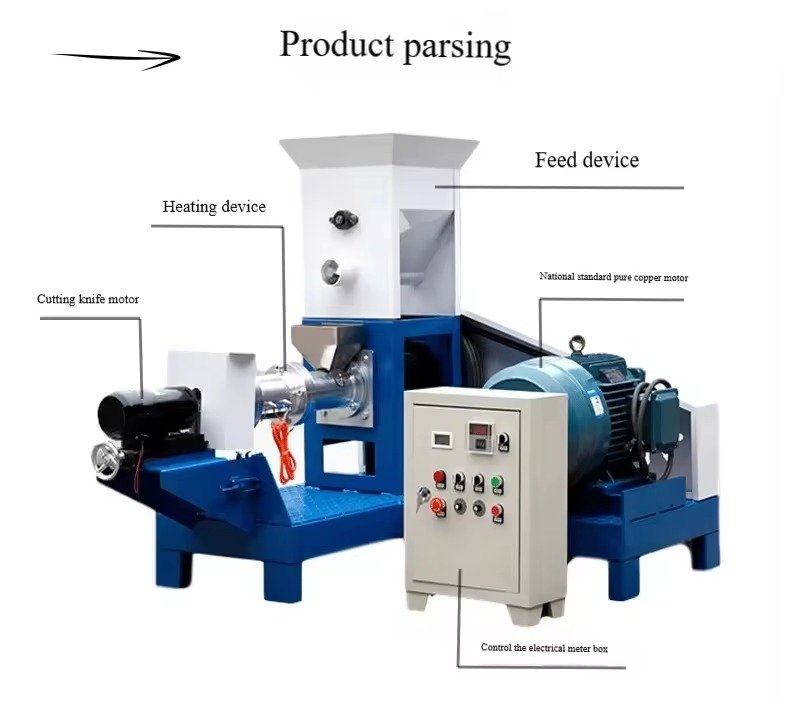

Advanced Features of MAIKONG Chicken Feed Machines

Our chicken feed machines incorporate innovative features that enhance performance, durability, and ease of operation. These advanced technologies set MAIKONG equipment apart from competitors and deliver exceptional value to South African poultry operations.

Precision Gear Transmission

Our chicken feed pellet machines feature high-efficiency gear transmission systems that occupy minimal space while ensuring even force distribution. This advanced design provides smooth operation, reduced noise levels, and simplified maintenance requirements.

Premium Siemens Motors

MAIKONG broiler pellet machines are equipped with high-quality Siemens motors that deliver reliable performance with low power consumption. These premium components ensure consistent operation even under demanding conditions, reducing downtime and maintenance costs.

Stainless Steel Components

Critical components such as the feeding auger, conditioner, and door cover are crafted from high-grade stainless steel. This premium material prevents corrosion, eliminates contamination risks, and significantly extends the service life of your chicken feed making pellet machine.

Precision Cutter Device

Our machines feature dual cutter blades that precisely control the length of finished pellets. This ensures consistent pellet size for optimal feed quality and digestibility, a critical factor for maximizing feed conversion efficiency in poultry operations.

Variable-Speed Feeding

The feeding system in our broiler pellet machine 4 ton models is controlled by a stepless frequency conversion motor, allowing precise adjustment of feed rate. This technology ensures optimal material flow and consistent pellet quality regardless of raw material variations.

Advanced Conditioning

MAIKONG offers multiple conditioner options including single-layer, double-layer, three-layer, and dual-axis differential designs. These advanced conditioning systems optimize moisture and temperature control for superior pellet quality and production efficiency.

Comprehensive Safety Features

Our chicken feed pellet machines incorporate multiple safety mechanisms, including overload protection safety pins and automatic motor shutdown when the door cover is opened. These features protect both operators and equipment during operation.

Aviation-Grade Gear Technology

MAIKONG employs high-precision aviation-grade gear grinding technology in our chicken feed making pellet machine price competitive models. This advanced manufacturing process ensures exceptionally smooth gear transmission and significantly reduces operational noise.

Ergonomic Design

Our machines feature user-friendly designs with enclosed transmission components and strategically positioned control panels. This ergonomic approach simplifies operation and maintenance while enhancing workplace safety for your feed production team.

Ready to Upgrade Your Feed Production?

Contact us today to discuss how our advanced chicken feed machines can improve your poultry operation’s efficiency and profitability.

Request Customized Solution

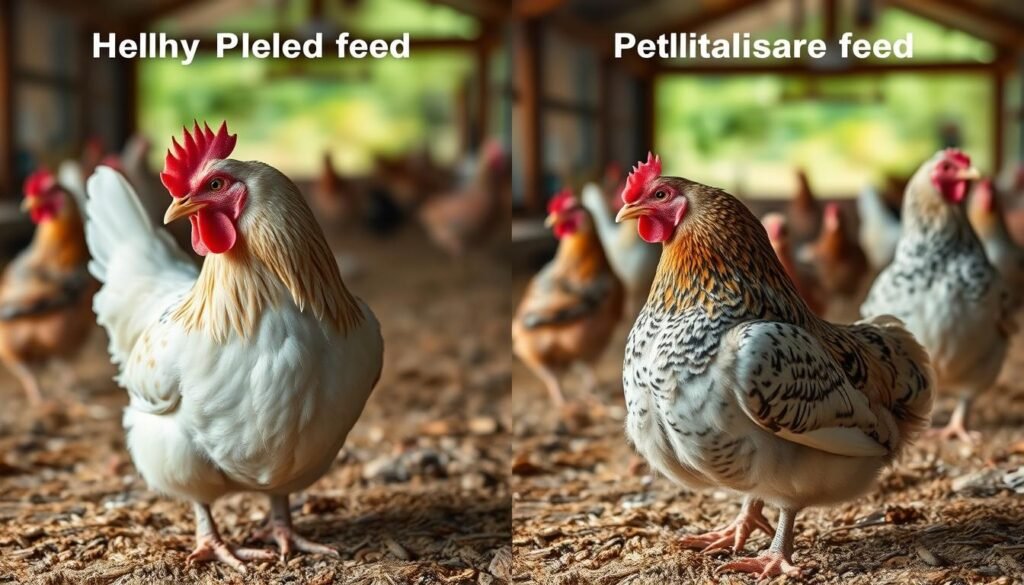

Benefits of Pelletized Feed for Poultry Operations

Advantages of Pelletized Feed

- Improved Feed Conversion Ratio (FCR) by 10-15%

- Reduced feed waste by up to 10% compared to mash feed

- Enhanced digestibility and nutrient absorption

- Elimination of selective feeding behavior

- Extended storage life with reduced mold risk

- Easier handling, transportation, and storage

- Destruction of harmful pathogens during pelleting process

- Consistent nutrition in every pellet

Challenges Without Pelletized Feed

- Higher feed waste and associated costs

- Inconsistent growth rates and bird uniformity

- Increased risk of nutritional imbalances

- Greater susceptibility to feed contamination

- More storage space required for equivalent feed volume

- Shorter shelf life and higher spoilage rates

- Difficulty incorporating certain additives uniformly

- Lower overall farm profitability

By investing in a MAIKONG chicken feed pellet machine, South African poultry operations can significantly improve feed efficiency, reduce production costs, and enhance overall farm profitability. Our machines produce high-quality, uniform pellets that deliver consistent nutrition to your birds, resulting in improved growth rates and better flock uniformity.

Pricing and Customization Options

Flexible Pricing to Meet Your Budget

MAIKONG offers competitive pricing on our complete range of chicken feed making pellet machine price options. Our standard models range from 7,000 to 100,000 USD, depending on capacity and features. We understand that each poultry operation has unique financial considerations, which is why we offer flexible payment terms to accommodate your budget requirements.

Customization Options

We provide extensive customization options for our chicken feed machines to ensure they perfectly match your specific production requirements:

Die Specifications

Choose from various aperture sizes (φ2mm~φ8mm) and materials (carbon steel or stainless steel) to produce the ideal pellet size and durability for your specific poultry feed requirements.

Conditioner Types

Select from single-layer, double-layer, three-layer, or dual-axis differential conditioners to optimize moisture and temperature control for your specific raw materials and production goals.

Control Systems

Choose from basic manual controls, semi-automatic systems, or fully automated touchscreen interfaces with comprehensive monitoring and adjustment capabilities.

Aesthetic Customization

Personalize your chicken pellet making machine with custom color options (blue, white, green, or custom colors) to match your existing equipment or brand identity.

Get Your Personalized Quote Today

Contact our sales team for a detailed quotation tailored to your specific requirements and production goals.

Comprehensive Customer Support

At MAIKONG, we believe that exceptional customer support is just as important as high-quality equipment. When you purchase our chicken feed machines, you gain access to our comprehensive support services designed to ensure your feed production operations run smoothly and efficiently.

Technical Consultation

Our experienced engineers provide expert guidance to help you select the optimal chicken feed pellet machine configuration based on your specific production requirements, space constraints, and budget considerations.

Installation Assistance

MAIKONG provides comprehensive installation guidance to ensure your chicken feed making pellet machine is properly set up for optimal performance. Our detailed documentation and remote support help streamline the installation process.

Operator Training

We offer comprehensive training programs to ensure your team understands how to operate, maintain, and troubleshoot your chicken feed machine effectively, maximizing productivity and equipment lifespan.

Spare Parts Supply

MAIKONG maintains a comprehensive inventory of genuine spare parts for all our broiler pellet machine models, ensuring quick replacement of wear components to minimize downtime and maintain optimal performance.

Remote Technical Support

Our technical team is available via WhatsApp to provide immediate assistance with troubleshooting, maintenance guidance, and operational questions for your chicken feed pellet machine.

Comprehensive Warranty

All MAIKONG chicken feed machines come with a standard warranty that covers manufacturing defects and component failures, providing peace of mind and protecting your investment in quality feed production equipment.

Why South African Poultry Operations Choose MAIKONG

MAIKONG has established itself as a trusted supplier of high-quality chicken feed machines to South African poultry operations of all sizes. Our commitment to engineering excellence, customer satisfaction, and ongoing support has made us the preferred choice for feed production equipment across the region.

By choosing MAIKONG’s advanced chicken feed pellet machines, you’re investing in equipment that delivers consistent performance, exceptional durability, and outstanding value. Our machines are designed to optimize your feed production process, reduce operational costs, and improve the overall profitability of your poultry business.

Contact us today to discover how MAIKONG’s chicken feed making pellet machine solutions can transform your poultry operation and help you achieve your production goals.

4.8

Customer Satisfaction