Our Factory proudly presents premium Lucerne Pellet Machines tailored for South African farmers and feed producers, designed to transform raw Lucerne (alfalfa) and other forage materials into high-nutrition pellets that boost livestock health and farm profitability. We understand the critical need for sustainable, cost-effective feed solutions across South Africa’s thriving dairy, cattle, and poultry industries, which is why our machines are engineered to process locally abundant materials like Lucerne, grasses, and crop residues into dense, uniform pellets with up to 22% protein content—ideal for enhancing milk yields in dairy cows and weight gain in beef cattle.

Our Product range includes robust ring-die pellet mills capable of handling capacities from 0.5 to 30 tons per hour, featuring advanced gearboxes and heat-treated alloy steel rollers that withstand Africa’s demanding conditions. Farmers using our machines report 30% less feed waste compared to loose hay, thanks to pellets’ compact size and reduced spoilage during storage. We integrate moisture control systems to ensure optimal 12–15% moisture levels in final pellets, preventing mold growth and maintaining nutritional integrity. For dairy farms in regions like Free State or Mpumalanga, our Lucerne pellet machines enable consistent feed quality year-round, overcoming seasonal forage shortages.

We also provide complete pellet plant solutions, from bale breakers and hammer mills to coolers and packaging systems, tailored for smallholder farms or large commercial operations. Our after-sales team offers on-site training for machine maintenance and die replacement, ensuring minimal downtime. By choosing our Lucerne pellet technology, South African farmers gain not just equipment but a partnership committed to elevating feed efficiency and profitability through proven, locally adapted solutions.

Transform your lucerne processing capabilities with MAIKONG’s advanced MK-Series lucerne pellet machine, engineered specifically for South African agricultural operations. Our high-efficiency pellet machines convert raw lucerne (alfalfa) into premium quality feed pellets with consistent density, enhanced nutritional preservation, and superior digestibility. As a leading manufacturer from SZ, GD, China, MAIKONG combines cutting-edge technology with competitive pricing to deliver lucerne pelleting solutions that maximize your production efficiency and feed quality.

MAIKONG: Leading Lucerne Pellet Machine Manufacturer

With over two decades of specialized experience in pelleting technology, MAIKONG has established itself as a premier supplier of lucerne pellet machines to the South African market. Our state-of-the-art manufacturing facilities in SZ, GD, and superior supply chain capabilities enable us to produce both high-end and cost-effective lucerne pelleting equipment that meets the diverse needs of South African feed producers.

Our Commitment to South African Clients

MAIKONG understands the unique challenges faced by South African agricultural operations. Our lucerne pellet machines are designed to withstand the demanding conditions of continuous operation while maintaining optimal performance. We provide comprehensive technical support, spare parts availability, and customization options to ensure your pelleting operation runs smoothly year-round.

Superior Supply Chain Advantages

Our established supply chain network enables us to source premium components while maintaining competitive pricing. This advantage translates directly to our clients through:

- Faster delivery times to South African ports

- Consistent quality control across all components

- Cost-effective replacement parts

- Flexible production capabilities to meet custom requirements

Ready to Enhance Your Lucerne Processing?

Our technical consultants are available to discuss your specific requirements and recommend the ideal MK-Series lucerne pellet machine for your operation.

Contact via WhatsApp

Email Us

Why Process Lucerne into Pellets?

Converting raw lucerne into pellets offers significant advantages for South African agricultural operations. The pelleting process transforms bulky alfalfa into compact, nutrient-dense feed that optimizes storage, transportation, and animal nutrition.

Improved Storage Efficiency

Lucerne pellets require up to 75% less storage space than raw hay, allowing South African operations to maximize warehouse capacity and reduce storage costs. The dense pellet format also significantly extends shelf life by reducing moisture content and preventing mold growth.

Enhanced Nutritional Value

The pelleting process preserves critical nutrients while improving digestibility. South African livestock operations report improved feed conversion ratios and enhanced animal performance when using properly processed lucerne pellets compared to traditional feeding methods.

Reduced Transportation Costs

For South African operations dealing with long transport distances, lucerne pellets offer substantial savings. The increased density means more nutritional value per truckload, reducing fuel costs and environmental impact while simplifying logistics.

Benefits of Lucerne Pellets

- Reduced storage space requirements (up to 75% less)

- Extended shelf life (12+ months vs. 3-6 months for hay)

- Minimized feed waste during handling and consumption

- Improved digestibility and nutrient absorption

- Consistent feed quality and nutrient profile

- Simplified transportation and reduced logistics costs

- Elimination of dust and associated respiratory issues

- Potential for value-added export products

Challenges Without Pelleting

- Excessive storage space requirements for raw hay

- Significant feed waste during handling and feeding

- Inconsistent feed quality between batches

- Higher transportation costs per nutrient unit

- Increased risk of mold and spoilage

- Dust-related health concerns for livestock

- Limited market options compared to processed products

- Difficulty in precise ration formulation

MK-Series Lucerne Pellet Machine Specifications

MAIKONG offers a comprehensive range of lucerne pellet machines to meet the diverse needs of South African agricultural operations. From small-scale farms to large commercial feed mills, our MK-Series provides the ideal solution for efficient alfalfa processing.

| Model |

Output (t/h) |

Main Motor Power (kW) |

Ring Die Diameter (mm) |

Pellet Diameter (mm) |

Weight (kg) |

| MK-SZLH250 |

1~1.5 |

22 |

250 |

2~12 |

1800 |

| MK-SZLH320 |

3~4 |

37 |

320 |

2~12 |

2500 |

| MK-SZLH350 |

5~6 |

55 |

350 |

2~12 |

3500 |

| MK-SZLH420 |

10~12 |

110 |

420 |

2~12 |

4000 |

| MK-SZLH508 |

15~16 |

160 |

508 |

2~12 |

4300 |

| MK-SZLH558 |

20~22 |

185 |

558 |

2~12 |

4800 |

| MK-SZLH678 |

30~33 |

250 |

673 |

2~12 |

5000 |

| MK-SZLH768 |

38~40 |

315 |

762 |

2~12 |

5500 |

Equipment Configuration: All MK-Series lucerne pellet machines feature stainless steel ring dies, 6mm SUS304 granulation room door covers, 3mm SUS304 feed chutes, HT250 gear boxes, 42CrMo gears, 20CrMnTi gear shafts, 42CrMo spindles and empty shafts, imported bearings, German/Taiwan oil seals, safety pin overload protection, serpentine spring coupling drive, and Siemens motors.

Find Your Ideal Lucerne Pellet Machine

Not sure which model best suits your operation? Our technical team can help determine the optimal configuration based on your production requirements.

Request Technical Consultation

Technical Features of MK-Series Lucerne Pellet Machine

MAIKONG’s lucerne pellet machines incorporate advanced engineering features that ensure reliable performance, consistent pellet quality, and long service life even under demanding South African operating conditions.

Advanced Gear Transmission

The MK-Series features a high-precision gear transmission system that delivers 20% higher output compared to belt-drive alternatives. The 42CrMo gears and 20CrMnTi gear shafts ensure smooth operation and exceptional durability under continuous production conditions.

Premium Siemens Motors

All MK-Series machines are equipped with genuine Siemens motors, providing reliable power delivery, energy efficiency, and exceptional service life. These premium motors ensure consistent performance even during extended production runs common in South African operations.

Stainless Steel Components

Critical components including the conditioner, feed chute, and door cover are manufactured from high-grade SUS304 stainless steel. This prevents contamination, ensures hygienic operation, and extends equipment life even when processing high-moisture lucerne materials.

Comprehensive Safety Features

MK-Series machines incorporate multiple safety systems including overload protection safety pins, emergency stop buttons, and automatic shutdown mechanisms. The enclosed transmission system and safety interlocks protect operators while ensuring regulatory compliance.

Customizable Ring Dies

The MK-Series offers interchangeable ring dies with apertures ranging from 2mm to 12mm. This flexibility allows South African operators to produce pellets optimized for different livestock species or adapt to varying lucerne material characteristics throughout the season.

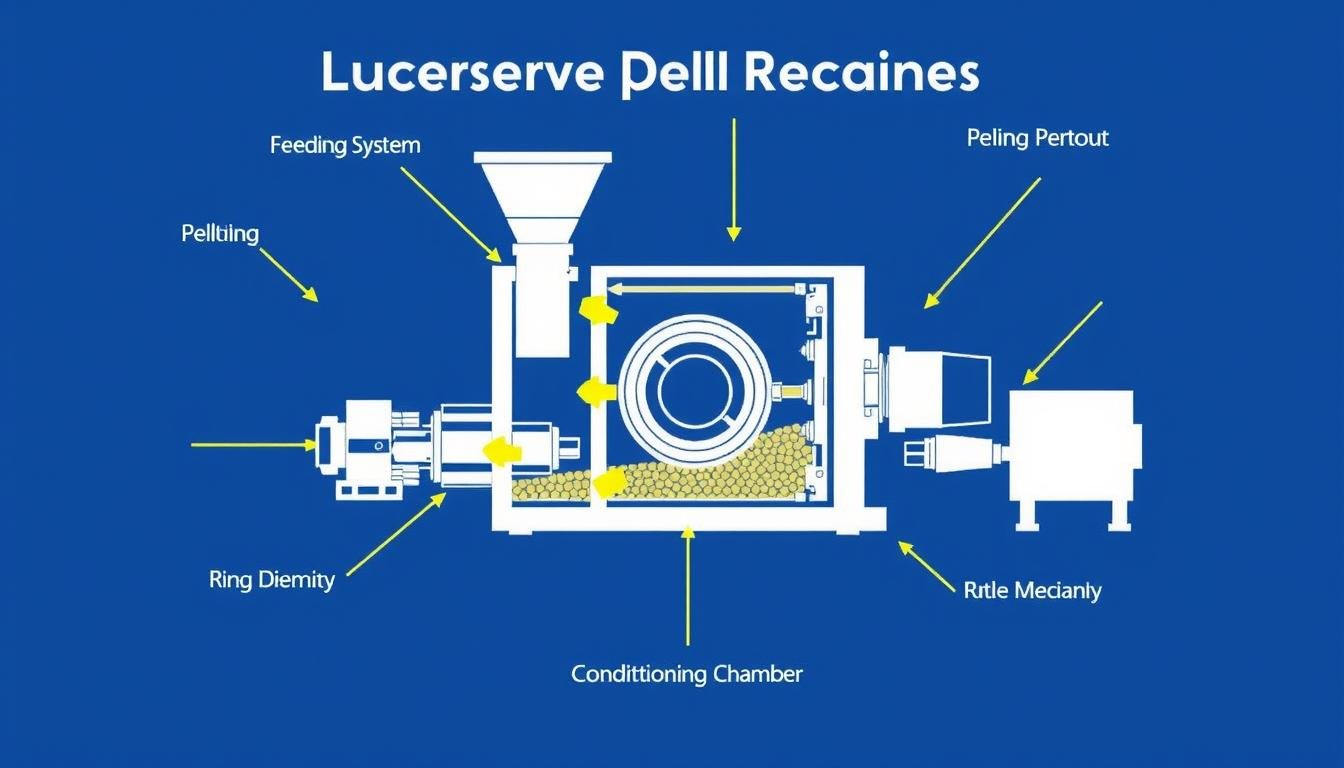

Innovative Feeding System

Specially designed for fibrous materials like lucerne, our feeding mechanism ensures uniform material flow and prevents bridging or blockages. The system includes an anti-arching feeder, conditioner, and force feeder to maintain consistent production rates even with variable material characteristics.

Overall Performance Rating

4.8

Exceptional

Maintenance Requirements

4.6/5

Operational Flexibility

4.7/5

Working Principle of Lucerne Pellet Machine

Understanding how the MK-Series lucerne pellet machine operates helps operators optimize performance and maintain efficient production. The pelleting process involves several key stages that transform raw lucerne into high-quality feed pellets.

-

Material Feeding

The crushed and properly conditioned lucerne material enters the pelleting chamber through the speed-regulating feeder and force feeder from the storage hopper. The feeding rate is precisely controlled to ensure optimal chamber loading.

-

Material Distribution

Through gravity, centrifugal force from the rotating ring die, and the action of the feeding scraper, the material is evenly distributed into the pressing zones between the rollers and ring die.

-

Compression and Extrusion

As the ring die rotates, it drives the pressure rollers to rotate. The minimal gap (0-0.15mm) between the rollers and ring die inner wall creates intense pressure that compacts the material and forces it through the die holes.

-

Pellet Formation

Inside the die holes, the compressed material forms solid pellets as it moves through the channel. The friction generates heat that activates natural binders in the lucerne, creating cohesive pellets.

-

Cutting and Discharge

As the formed pellets emerge from the outer surface of the ring die, adjustable knives cut them to the desired length. The finished pellets are then discharged for cooling and further processing.

Optimal Processing Parameters for Lucerne

- Moisture Content: 14-16% for optimal pelleting

- Particle Size: 2-3mm for balanced compression and binding

- Die Temperature: 75-90°C for natural lignin activation

- Conditioning Time: 30-90 seconds for proper moisture distribution

- Pellet Cooling: Required to reduce moisture to below 12% for storage stability

Applications of Lucerne Pellet Machine in South Africa

The versatility of MAIKONG’s lucerne pellet machines makes them ideal for various applications across South Africa’s diverse agricultural landscape. From small-scale farms to large commercial operations, our equipment supports multiple industries and production needs.

Cattle Feed Production

South African cattle operations benefit from lucerne pellets’ high protein content (16-22%) and balanced fiber levels. The pelleted format reduces waste, improves rumen function, and supports consistent weight gain in beef cattle and sustained milk production in dairy herds.

Sheep and Goat Nutrition

For South Africa’s extensive sheep and goat farming sector, lucerne pellets provide an ideal supplementary feed. The pellets’ consistent size prevents selective feeding, ensures uniform nutrition, and supports reproductive performance in breeding stock.

Horse Feed Formulation

South Africa’s growing equine industry relies on high-quality lucerne pellets as a foundation for balanced horse nutrition. The pelleted format reduces dust (minimizing respiratory issues), prevents waste, and provides consistent nutrition for performance horses.

Commercial Feed Mills

Large-scale South African feed manufacturers use our high-capacity models to incorporate lucerne pellets into various feed formulations. The consistent quality and reliable production rates support efficient large-volume operations and just-in-time production schedules.

Export Product Development

South African agricultural enterprises leverage our pelleting technology to create value-added export products. The dense, stable pellet format significantly reduces shipping costs and extends shelf life, opening new markets across Africa and beyond.

Game Farm Operations

South Africa’s unique game farming sector utilizes lucerne pellets as supplementary feed during dry seasons. The pellets’ nutritional consistency and storage stability make them ideal for remote game farm operations with challenging logistics.

Ready to Optimize Your Lucerne Processing?

Contact our specialists to discuss how MAIKONG’s lucerne pellet machines can be tailored to your specific agricultural application.

WhatsApp Consultation

Email Inquiry

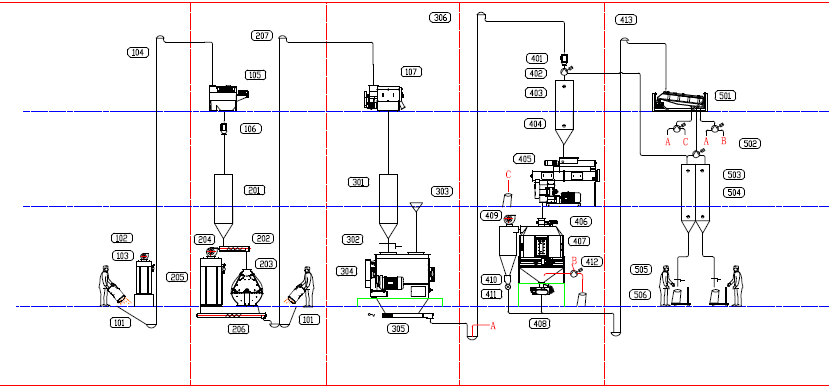

Complete Lucerne Pellet Production Line Solutions

Beyond individual pelleting machines, MAIKONG offers comprehensive lucerne pellet production line solutions tailored to South African operational requirements. Our turnkey systems integrate all necessary equipment for efficient processing from raw material to finished pellets.

Standard Production Line Components

Raw Material Processing

- Bale Breaker: Efficiently breaks down compressed lucerne bales

- Hammer Mill: Reduces particle size to optimal 2-3mm for pelleting

- Cleaning Screen: Removes foreign materials and ensures quality

- Dryer (if needed): Adjusts moisture content to ideal 14-16% range

Pelleting and Finishing

- Mixer: Ensures uniform blending of materials and additives

- Pellet Mill: Core MK-Series machine for compression and forming

- Cooler: Reduces pellet temperature and stabilizes moisture

- Screener: Removes fines and ensures uniform pellet quality

- Packaging System: Weighs and packages final product

Customized Production Line Configurations

| Production Scale |

Recommended Configuration |

Output Capacity |

Space Requirement |

Estimated Investment (USD) |

| Small Farm Operation |

MK-SZLH250 with basic processing equipment |

1-1.5 t/h |

300-500m² |

$20,000-$50,000 |

| Medium Commercial |

MK-SZLH350 with complete processing line |

5-6 t/h |

700-1000m² |

$70,000-$120,000 |

| Large Industrial |

MK-SZLH508 with automated processing system |

15-16 t/h |

1500-2000m² |

$150,000-$300,000 |

| Feed Mill Integration |

MK-SZLH678 with advanced automation |

30-33 t/h |

2500-3500m² |

$250,000-$450,000 |

Production Line Design Services

MAIKONG provides comprehensive design services for South African clients planning new lucerne processing facilities or upgrading existing operations. Our engineering team works closely with you to develop optimized layouts that consider:

- Available space constraints

- Production capacity requirements

- Raw material characteristics

- Energy efficiency optimization

- Future expansion possibilities

- Automation requirements

- Operator ergonomics and safety

- Maintenance accessibility

- Local regulatory compliance

- Environmental considerations

- Integration with existing systems

- Budget optimization

Plan Your Complete Lucerne Processing Facility

Our engineering team can develop a customized production line design based on your specific requirements and constraints.

Request Facility Design Consultation

Lucerne Pellet Machine Pricing Information

MAIKONG offers competitive pricing on our complete range of lucerne pellet machines for the South African market. Our transparent pricing structure ensures you receive excellent value while maintaining the highest quality standards.

Standard Pricing Guidelines

MK-Series lucerne pellet machine FOB pricing ranges from USD 7,000 to USD 100,000 depending on model and specifications. This pricing includes the standard machine configuration with all core components.

Factors Affecting Pricing

- Production Capacity: Higher output models command premium pricing

- Ring Die Specifications: Material type and aperture size influence cost

- Motor Power and Brand: Higher power ratings and premium brands affect pricing

- Control System Complexity: Advanced automation increases investment

- Customization Requirements: Special modifications may impact final price

Value-Added Services

- Installation Support: On-site technical assistance available

- Operator Training: Comprehensive training programs included

- Warranty Coverage: Extended warranty options available

- Spare Parts Package: Essential components for maintenance

- Technical Documentation: Complete manuals in English

Special Offer for South African Clients

MAIKONG is currently offering preferential pricing and extended warranty coverage for South African agricultural operations. Contact our sales team for details on current promotions and volume discounts available for your region.

Payment and Shipping Terms

Standard Payment Terms

- 40% deposit upon order confirmation

- 60% balance before shipment

- T/T (Telegraphic Transfer) or L/C (Letter of Credit) accepted

- Flexible payment arrangements available for returning clients

Shipping Information

- Delivery time: 10-30 days for standard machines

- 30-90 days for complete production lines

- FOB Chinese port (typically Shenzhen)

- Shipping to all major South African ports

- Complete export documentation provided

Request a Detailed Quotation

Contact our sales team for a comprehensive quotation tailored to your specific requirements and delivery location in South Africa.

Email for Quotation

WhatsApp Inquiry

Frequently Asked Questions About Lucerne Pellet Machines

Our South African clients often have specific questions about lucerne pellet machines and their operation. Here are answers to the most common inquiries we receive.

What is the minimum moisture content required for lucerne pelleting?

For optimal pelleting of lucerne (alfalfa), the moisture content should be between 14-16%. If the raw material is too dry (below 12%), steam conditioning may be required to add moisture and improve binding. If too wet (above 18%), pre-drying is recommended to prevent clogging and achieve proper pellet density and durability.

Can the MK-Series process both pure lucerne and mixed feed formulations?

Yes, all MK-Series lucerne pellet machines can process both 100% pure lucerne and mixed formulations. The machines perform exceptionally well with pure lucerne but can also handle blends containing grains, minerals, and other additives. When processing mixed formulations, output capacity may increase due to improved flow characteristics compared to pure fibrous materials.

What is the recommended particle size for lucerne before pelleting?

The optimal particle size for lucerne before pelleting is approximately 2-3mm. This size provides the best balance between compression efficiency and proper binding. Larger particles may cause uneven pellets or excessive wear on dies, while finer particles may lead to excessive friction and energy consumption. We recommend using a hammer mill with appropriate screen size to achieve consistent particle reduction.

How does the output capacity change when processing different materials?

Output capacity varies significantly depending on material composition:

- 100% lucerne: Achieves approximately 70-80% of the rated capacity

- 70% lucerne + 30% grains: Achieves 85-95% of rated capacity

- 50% lucerne + 50% grains: May achieve 100% or slightly higher than rated capacity

This variation occurs because fibrous materials like lucerne have lower density and different flow characteristics compared to grains. When selecting a machine, consider your specific material mix to ensure adequate production capacity.

What maintenance is required for lucerne pellet machines?

Regular maintenance for MK-Series lucerne pellet machines includes:

- Daily: Inspection of wear parts, cleaning of die and roller surfaces

- Weekly: Lubrication of bearings, checking belt/chain tension

- Monthly: Comprehensive inspection of all components, tightening of fasteners

- Quarterly: Gear oil replacement, comprehensive bearing inspection

Ring dies and rollers typically require replacement after processing 1,500-2,000 tons of material, though this varies based on material abrasiveness and operating conditions. MAIKONG provides detailed maintenance schedules and training to maximize equipment life.

Do you provide installation and training services in South Africa?

Yes, MAIKONG offers comprehensive installation supervision and operator training services throughout South Africa. Our technical team can travel to your facility to oversee installation, conduct initial startup, and provide hands-on training for your operators. We also offer remote installation guidance via video conferencing for clients who prefer this option. All machines come with detailed installation manuals and video guides in English.

Why Choose MAIKONG Lucerne Pellet Machines

When selecting a lucerne pellet machine for your South African operation, MAIKONG offers distinct advantages that ensure long-term value and operational success.

Manufacturing Excellence

- Advanced production facilities in SZ, GD with strict quality control

- Premium materials including 42CrMo steel and SUS304 stainless steel

- Precision CNC machining for critical components

- Comprehensive testing before shipment

- ISO9001-certified manufacturing processes

Technical Superiority

- 20% higher output than comparable models

- Energy-efficient design reduces operational costs

- Advanced gear transmission for smoother operation

- Genuine Siemens motors and premium bearings

- Optimized for fibrous materials like lucerne

Customer Support

- Dedicated technical consultants for South African market

- WhatsApp technical support available 24/7

- Comprehensive installation and training services

- Readily available spare parts inventory

- Detailed documentation in English

Our Commitment to South African Clients

Quality Assurance

Every MAIKONG lucerne pellet machine undergoes rigorous testing before shipment. Our multi-stage quality control process includes component inspection, assembly verification, no-load testing, and full-load performance evaluation to ensure your equipment arrives ready for immediate implementation.

Ongoing Technical Support

Our commitment extends beyond equipment delivery. MAIKONG provides comprehensive technical support throughout the equipment lifecycle, including troubleshooting assistance, optimization guidance, and process improvement recommendations tailored to South African operating conditions.

Experience the MAIKONG Difference

Join the growing number of satisfied South African agricultural operations benefiting from MAIKONG’s superior lucerne pellet machines and exceptional support.

Contact Us Today

Transform Your Lucerne Processing with MAIKONG

MAIKONG’s MK-Series lucerne pellet machines offer South African agricultural operations the perfect combination of advanced technology, reliable performance, and exceptional value. By choosing MAIKONG, you gain access to industry-leading equipment backed by comprehensive support and decades of manufacturing expertise.

Whether you’re establishing a new lucerne processing facility or upgrading existing equipment, our team is committed to ensuring your success. From initial consultation through installation, training, and ongoing support, MAIKONG stands with you at every step of your lucerne pelleting journey.

Contact us today to discover how our lucerne pellet machines can enhance your operation’s efficiency, product quality, and profitability in South Africa’s competitive agricultural market.