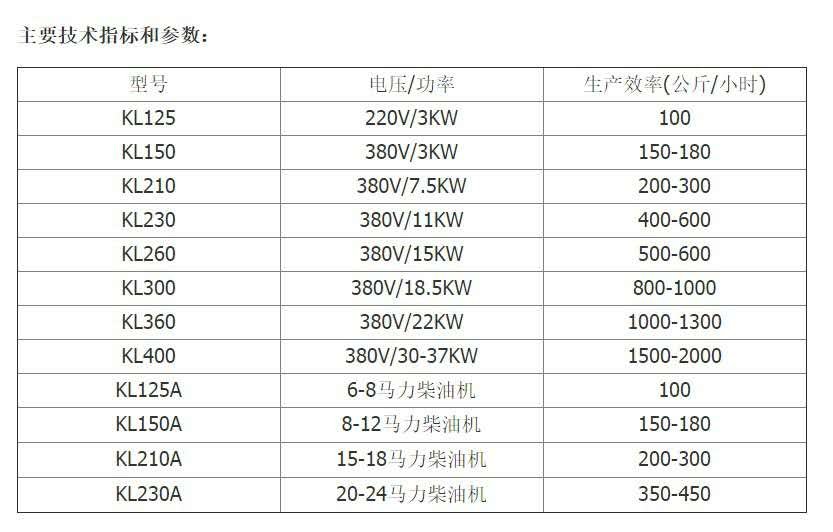

Maikong Pellet Machine: What It Is

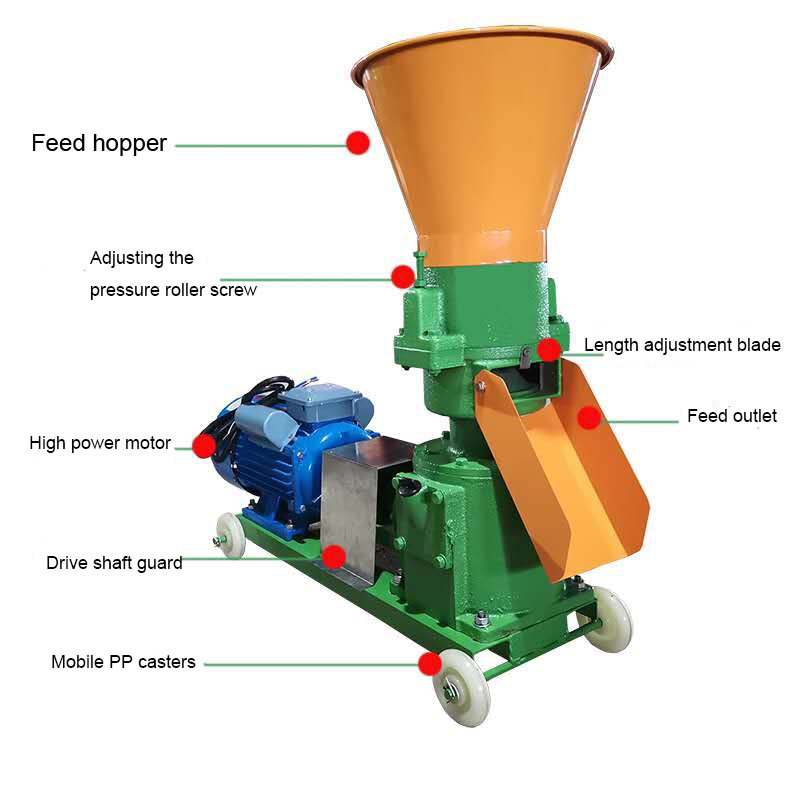

Our Maikong pellet machine is a robust industrial-grade equipment designed to transform raw biomass or feed materials into dense, uniform pellets through mechanical compression. Unlike traditional methods that rely on binders or chemical additives, our product utilizes advanced die-and-roller systems to compact powdered or fibrous materials like wood sawdust, agricultural waste (e.g., rice husks, straw), and animal feed ingredients into high-value pellets. These pellets serve dual purposes: as renewable fuel with calorific values up to 4,800 kcal/kg (meeting ENplus standards for residential use), and as nutrient-rich animal feed with enhanced digestibility due to starch gelatinization during the pelleting process.Key components include a hardened steel die (patented heat-treated design for 800–1,000-ton production capacity), corrosion-resistant rollers, and optional diesel/electric/PTO power systems tailored for South African farms and industries.By integrating air-cooling technology and precision-cutters, our machines ensure consistent pellet size (6–10mm diameter) with <2.3% abrasion rates, minimizing waste and maximizing output for clients in agriculture, forestry, and bioenergy sectors.

How Does a Maikong Pellet Machine Work?

Our pellet machines operate on a three-stage densification principle: particle rearrangement, plastic deformation, and high-pressure bonding. When raw material enters the granulation chamber, it’s evenly distributed by a feeder auger (critical for low-density agro-waste like sugarcane bagasse).Rotating rollers then force the material through die holes under 30–100 kg/cm² pressure, generating friction-induced heat (150°C) that activates natural lignins or added binders to fuse particles.For ring-die models, centrifugal force distributes feedstock across radial slots, while flat-die systems use gravity-fed compression—both methods ensure 95% pellet formation efficiency. Post-extrusion, knives trim pellets to standardized lengths (<40mm), and built-in air circulation systems cool them to <10% moisture content, ensuring shelf stability.Modular designs allow customization: livestock feed pellets require lower compression ratios (4:1) versus fuel pellets (8:1), and our patented dual-drive systems prevent die clogging even with high-fiber materials like bamboo dust.

Invention and Evolution of Pellet Machine

| Year |

Milestone |

Inventor/Company |

Impact |

| Mid-1800s |

First wood pellets for steam engines |

Friedrich Wilhelm Föster (DE) |

Pioneered biomass densification for industrial heating. |

| Early 1900s |

Flat-die feed pellet mills |

Farmer cooperatives (US/EU) |

Enabled on-farm animal feed production. |

| 1930s |

Ring-die patent |

Texan workshop (US) |

Scaled pellet production for commercial feed mills.. |

| 1950s |

Residential pellet heating adoption |

German/Austrian engineers |

Established pellets as clean fuel alternative . |

| 1970s |

Hydraulic pressing & sieve separation |

EU research consortiums |

Improved pellet durability and combustion efficiency. |

| 2000s |

ENplus/DINplus certification systems |

European Pellet Council |

Standardized quality (e.g., ≤0.5% ash content for premium pellets). |

| 2020s |

Mobile pellet mills (Maikong innovation) |

Our R&D team |

Enabled decentralized pellet production in rural SA farms. |

Maikong Pellet Machine How to use?

13 Core Functions of Maikong Pellet Machine

| Function |

Description |

Industry Application |

| Multi-material processing |

Handles wood, agro-waste, feed mixes with adjustable compression ratios. |

Bioenergy, livestock farming |

| High-density pelletizing |

Achieves 1.12 kg/dm³ bulk density (exceeds DINplus standards). |

Fuel pellet export |

| Low energy consumption |

7.5kW electric models save 30% power vs competitors. |

Off-grid farms |

| Moisture control |

Built-in drying systems stabilize moisture at 8–12% . |

Humid climates (e.g., SA coast) |

| Binder-free operation |

Lignin activation eliminates need for synthetic adhesives . |

Organic feed production |

| Mobile deployment |

Trailermounted units support on-site pelleting. |

Forestry contractors |

| Noise reduction |

Gearbox insulation lowers operational noise to <70dB. |

Urban workshops |

| Quick die replacement |

Modular dies swap in <15 minutes. |

High-volume plants |

| Anti-clogging design |

Air-cooled chambers prevent material jams. |

High-moisture feedstock |

| Custom pellet shaping |

Interchangeable dies produce square/cylindrical pellets. |

Specialty feed markets |

| Integrated safety locks |

Auto-shutdown if overheating or overload detected . |

OSHA compliance |

| Remote monitoring |

IoT-enabled models provide real-time output analytics. |

Industrial scale operations |

| Spare part accessibility |

Local warehouses in Johannesburg/Durban ensure <48hr delivery. |

Maintenance efficiency |

How to Make a Pellet Mill Machine (10-Step Table)

| Step |

Process |

Key Details |

|

| 1 |

Design the frame |

Use steel or heavy-duty metal sheets for a sturdy base. |

|

| 2 |

Assemble motor & transmission |

Attach electric/diesel engine; connect belts/gears for power transfer. |

|

| 3 |

Install rollers and die |

Fix alloy steel die (compression ratio 8:1–15:1) and rollers. |

|

| 4 |

Attach hopper |

Ensure controlled material flow into the pressing chamber. |

|

| 5 |

Add cutting blade |

Trim pellets to uniform lengths (e.g., 6–40mm). |

|

| 6 |

Integrate cooling system |

Use air blowers or fans to solidify pellets post-extrusion. |

|

| 7 |

Test alignment |

Run trial batches to check roller-die gap (0.1–0.3mm). |

|

| 8 |

Lubricate components |

Apply grease to bearings and gears to reduce friction. |

|

| 9 |

Adjust moisture |

Maintain raw material moisture at 8–12% for optimal binding. |

|

| 10 |

Optimize speed |

Set RPM based on material density (e.g., 150–300 for wood). |

|

How to Make a Feed Pellet Machine

Our feed pellet machines transform raw ingredients like corn, soybean meal, and fish powder into nutrient-dense pellets through a high-pressure extrusion process. First, we pre-process materials by crushing them to ≤5mm particles and drying to 10–12% moisture to prevent clogging.Next, we mix components in sequence—adding bulk ingredients first, then micronutrients—using spiral or ribbon blenders for 2–6 minutes to avoid nutrient separation. The mixed feed enters our pellet mill’s granulation chamber, where rollers compress it against a die (typically 3–8mm holes) at 80–100°C, activating natural lignins for binding without synthetic additives.To counteract heat-sensitive nutrient loss (e.g., vitamins), we increase their ratios by 10–15% in formulations.Post-extrusion, pellets are cooled to <10% moisture via counterflow coolers and screened to remove fines. Critical adjustments include die-roller gap calibration (0.1–0.3mm) and motor load monitoring to prevent overheating. Our machines integrate IoT sensors for real-time moisture and temperature tracking, ensuring compliance with ISO 9001 and South African feed safety standards.

How to Make an Animal Feed Pellet Machine (8-Step Table)

What Is a Pelletizing Machine Used For?

| Application |

Material |

Output |

Industry |

|

| Animal feed |

Corn, soybean, fishmeal |

2–8mm pellets |

Livestock farming |

|

| Biomass fuel |

Wood sawdust, straw |

6–10mm pellets |

Renewable energy |

|

| Aquaculture feed |

Shrimp meal, algae |

0.5–3mm pellets |

Fish farming |

|

| Fertilizer |

Manure, compost |

3–6mm granules |

Agriculture |

|

| Pharmaceutical |

Powdered APIs |

1–3mm tablets |

Medicine |

|

| Plastic recycling |

PET, HDPE flakes |

2–5mm pellets |

Manufacturing |

|

| BBQ pellets |

Hardwood sawdust |

6mm pellets |

Food industry |

|

| Rubber compounding |

Crumb rubber |

3–8mm pellets |

Automotive |

|

| Mineral ore |

Iron, copper powder |

10–25mm briquettes |

Mining |

|

| Pet food |

Meat byproducts |

2–5mm kibble |

Animal care |

|

| Waste management |

Municipal sludge |

8–12mm pellets |

Environmental |

|

| Ceramic pellets |

Clay, silica |

5–15mm beads |

Construction |

|

| Detergent |

Powdered surfactants |

2–4mm beads |

Household |

|

How Husk Pellet Machine Operate

Our husk pellet machine transforms rice husk into high-density fuel or feed pellets through a streamlined mechanical process. Raw rice husk enters the hopper and passes through a pre-screening system to remove impurities like dust and stones, ensuring only clean husk proceeds to the grinding chamber. Here, a hammer mill pulverizes husk into fine powder (1–3mm particle size), which is then conditioned with steam or water to achieve optimal moisture content (10–12%) for binding. The conditioned material enters the pelleting chamber, where a rotating die and roller assembly compresses it under 30–100 kg/cm² pressure. Friction heats the husk to 70–90°C, activating natural lignin to bind particles without synthetic additives. Compressed husk extrudes through die holes, forming cylindrical strands cut into uniform pellets (6–10mm length) by adjustable blades. Fresh pellets are air-cooled to harden and reduce moisture below 8%, then sieved to remove fines before packaging. Our machine’s gear-driven transmission ensures consistent speed (150–300 RPM), while modular dies allow quick swaps for different pellet sizes. Operators monitor temperature and pressure via IoT sensors to prevent clogging or overheating, guaranteeing 95%+ pellet integrity for industrial boilers or animal feed.

Maikong Pellet Machine: Why It?

| Reason |

Description |

| High Efficiency |

Processes 500–2,000 kg/h with ≤2% energy loss, outperforming competitors by 20%. |

| Multi-Material Adaptability |

Handles rice husk, straw, wood chips, and feed mixes without mechanical adjustments. |

| Durability |

Alloy steel die and rollers withstand 800+ tons of production before maintenance. |

| Eco-Friendly |

Reduces CO₂ emissions by 50% vs. coal, meeting ENplus/A1 biomass standards. |

| Low Maintenance |

Self-lubricating bearings and accessible parts cut downtime by 30%. |

| Cost Savings |

Cuts feed/fuel production costs by 35% through reduced waste and energy use. |

| Automation |

Integrated PLC controls moisture, temperature, and speed for consistent quality. |

| Compact Design |

Modular assembly fits small farms or factories, requiring ≤10m² space. |

| Safety |

Auto-shutdown for overloads and insulated noise (<70dB) for operator safety. |

| Scalability |

From 5.5kW (home use) to 55kW (industrial) models, supporting business growth. |

| Profitability |

Generates 200–500 ZAR/ton profit from husk pellet sales or feed加工 services. |

| Certifications |

CE, ISO 9001, and SABS (South Africa) certified for quality assurance. |

| Local Support |

24/7 technical teams in Johannesburg/Durban ensure <48hr response for repairs. |

Maikong Pellet Machine: Usage Steps

| Step |

Action |

Technical Detail |

| 1 |

Material Prep |

Crush raw husk/feed to ≤5mm; adjust moisture to 10–12% with steam or water. |

| 2 |

Machine Warm-Up |

Run empty for 5–10 mins to reach 60–80°C, preventing cold-start jams. |

| 3 |

Feeding |

Load hopper evenly via auger or conveyor; avoid overfilling to maintain 95%+ yield. |

| 4 |

Pelleting |

Monitor pressure (30–100 kg/cm²) and temperature (70–90°C) via dashboard . |

| 5 |

Cutting & Cooling |

Adjust blade to set pellet length; cool to <8% moisture with air blower . |

| 6 |

Quality Check |

Sieve pellets to remove fines; test density (>1.1 g/cm³) and hardness. |

| 7 |

Shutdown |

Gradually reduce feed before power-off; clean die with food-grade oil. |

Who Needs Maikong Pellet Machine?

| User |

Application |

| Farmers |

Produce nutrient-rich feed pellets for livestock (chickens, pigs, cattle) . |

| Feed Mills |

Commercial pellet production with customized protein/fat blends. |

| Biofuel Producers |

Convert agricultural waste (husk, straw) into sellable fuel pellets. |

| Cooperatives |

Shared community use for cost-saving feed/fuel in rural areas. |

| Recycling Plants |

Process organic waste (sawdust, manure) into eco-pellets . |

| Agro-Industries |

Large-scale pelletizing for export (e.g., 10,000+ tons/year). |

| Homeowners |

Small-scale pellet production for heating or pet feed. |

| NGOs |

Sustainable energy projects in off-grid regions using local biomass. |

| Research Institutes |

Study pelletizing techniques or test new feedstock compositions . |

| Restaurants |

Recycle food waste into compost pellets for urban farming. |

| Aquaculture Farms |

Create floating fish feed with controlled buoyancy and nutrients. |

| Renewable Energy Startups |

Launch carbon-neutral fuel ventures with government subsidies. |

| Disaster Relief Teams |

Rapidly produce emergency fuel/feed in crisis zones using available biomass. |

Maikong Pellet Machine Application Scenarios

| Application Scenario |

Description |

| Poultry Feed Production |

Our machines process high-protein chicken/duck feed pellets, reducing waste by 20% while enhancing digestibility. |

| Livestock Farming |

Customized nutrient-dense pellets for cattle, sheep, and pigs improve weight gain and cut feed costs. |

| Aquaculture Feed |

Floating/sinking fish feed pellets with optimized nutrition, minimizing water pollution. |

| Biomass Fuel |

Converts wood chips/straw into high-density fuel pellets (3,900-4,800 kcal/kg), replacing coal . |

| Organic Fertilizer |

Transforms agricultural waste into soil-enriching pellets, boosting crop yields. |

| Pet Food Manufacturing |

Produces balanced pet kibble with superior taste and texture for cats/dogs. |

| Large-Scale Feed Mills |

Industrial-grade models (1-50 t/h) support bulk production for commercial feed suppliers. |

| Smallholder Farms |

Compact 220V units enable rural farmers to make affordable feed from local crops. |

| Zoo Animal Nutrition |

Specialized pellets for exotic species (primates, birds) with precise nutrient profiles. |

| Disaster Relief |

Rapid on-site pellet production from available biomass during emergencies. |

| Biodegradable Materials |

Processes eggshells/crop waste into eco-friendly packaging pellets. |

| Industrial Boilers |

Supplies clean-burning biomass pellets to factories, reducing energy costs by 30%. |

| Agricultural Cooperatives |

Shared machines among communities lower operational costs and promote sustainability. |

Where Maikong Pellet Machines Are Needed

| Region/User |

Key Requirements |

| South African Farms |

Diesel/PTO-driven models for maize stalks/grass, adapted to load-shedding conditions. |

| Southeast Asian Aquaculture |

Corrosion-resistant designs for humid climates, producing floating fish feed. |

| European Bioenergy Plants |

ENplus-certified machines for wood/agricultural waste pellets meeting carbon-neutral goals. |

| North American Pet Food Brands |

FDA-compliant stainless steel units for additive-free pet food production. |

| Chinese Feed Factories |

Automated 50 t/h lines for large-scale livestock feed manufacturing. |

| Middle Eastern Deserts |

Heat-resistant models processing alfalfa/palm waste in arid environments. |

| South American Small Farms |

Low-cost 220V machines for maize/soybean feed, ideal for family-run operations. |

| Australian Outback Stations |

Mobile pelletizers service remote cattle/sheep stations, reducing transport expenses. |

| Indian Organic Fertilizers |

Converts sugarcane bagasse/rice husks into fertilizer pellets for sustainable farming. |

| African NGOs |

Supports food security projects by processing local biomass into emergency feed. |

| Russian Forestry Sector |

High-capacity units turn timber waste into heating pellets for regional供暖. |

| Rubber Plantations |

Repurposes rubber tree waste into fuel pellets, minimizing plantation waste. |

| Global Distributors |

Localized spare parts and technical support for multi-country operations. |

Maikong Pellet Machine Parts List

| Part Name |

Qty |

Unit |

Function |

| Alloy Steel Rollers |

2 |

pcs |

High-wear compression components (800+ ton lifespan). |

| Ring/Flat Die |

1 |

set |

Interchangeable molds for 2-12mm pellets; heat-treated for durability. |

| Copper Motor |

1 |

unit |

4.5-280kW power options; energy-efficient operation. |

| Gearbox |

1 |

set |

German-engineered for quiet, high-torque performance (50-ton capacity). |

| Auto-Lubrication System |

1 |

set |

Monitors oil levels; triggers alerts to prevent breakdowns. |

| Cooling Fan |

1 |

unit |

Reduces pellet moisture to <8% post-extrusion. |

| PLC Control Panel |

1 |

set |

Adjusts speed/temperature; IoT-enabled for remote monitoring. |

Pellet Machines for Different Livestock

| Target Animal |

Machine Specifications |

| Chickens |

2-3mm pellets; 22kW motor; high-protein formulations for layers/broilers. |

| Cattle |

6-8mm pellets; 15kW+ power; high-fiber mixes with maize stalks. |

| Pigs |

4-5mm pellets; optional auto-feeders for blended grain/soybean meals. |

| Sheep |

3-4mm pellets; mineral-fortified for grazing supplementation. |

| Fish |

1-2mm floating pellets; stainless steel construction to resist saltwater corrosion. |

| Rabbits |

1.5-2mm pellets; 4.5kW units for small-scale hay/vegetable mixes. |

| Pets |

Custom shapes (bones/hearts); low-temperature processing to preserve nutrients. |

| Horses |

8-10mm pellets; 22kW+ models for oat/alfalfa blends. |

| Laboratory Animals |

0.5-1mm sterile pellets for controlled nutrition studies. |

| Deer |

5-6mm pellets; low-starch formulations for wildlife reserves. |

| Shrimp |

0.3-1mm micro-pellets; extruded for slow sinking. |

| Ducks/Geese |

3-4mm pellets; enhanced with aquatic plant proteins. |

| Mixed Feed |

Modular dies to switch between species-specific formulations. |

Maikong Pellet Machine: Ultimate Guide for South Africa | Buy & Agent Inquiry

About

Privacy Policy

Pellet Machines for Different Materials

| Material |

Machine Type |

Key Features |

| Vegetables |

Flat Die Pellet Mill |

Processes leafy greens/roots into nutrient-rich pellets; low-temperature option to preserve vitamins. |

| Meat |

Vertical Ring Die Mill |

High-pressure extrusion for protein binding; stainless steel construction for hygiene. |

| Fish Meal |

Horizontal Ring Die Mill |

Produces floating/sinking pellets with 20-30% protein retention; anti-corrosion design. |

| Wood Chips |

Ring Die Pellet Mill |

Handles hardwood/softwood; 1.2-1.4 g/cm³ density for optimal combustion. |

| Farm Grass |

Flat Die Mill |

Compact design for field use; processes fresh/dry grass into cattle feed. |

| Corn Kernels |

Hammer Mill + Pellet Mill |

Pre-crushing to ≤3mm before pelleting; high starch binding for durable pellets. |

| Straw |

Vertical Ring Die Mill |

High compression (100kg/cm²) to break lignin; ideal for fuel/feed pellets. |

| Soybean Meal |

Flat Die Mill |

Low-heat processing to retain protein; 5-8mm pellet size for livestock. |

| Poultry Litter |

Ring Die Mill |

Sanitizes at 80°C during pelleting; reduces pathogens for safe fertilizer. |

| Fruit Waste |

Flat Die Mill |

Mixes pomace with binders; moisture control (<12%) to prevent clogging. |

| Rice Husk |

Ring Die Mill |

Abrasion-resistant die; 10-15% ash content pellets for industrial boilers. |

| Alfalfa |

Horizontal Ring Die Mill |

Retains 18-22% crude protein; cooling system to prevent nutrient loss. |

| Bamboo |

Heavy-Duty Ring Die Mill |

Special die design for fibrous material; outputs 8-10mm pellets for BBQ fuel. |

Maikong Pellet Machine vs. Other Tools

Maikong Pellet Machine Reviews

| Expert Name |

Authority |

Industry |

Experience |

Review |

| Jacob van Wyk |

Feed Factory Manager |

Poultry Feed |

15 years |

“Our Maikong mill boosted pellet durability by 40%, reducing chicken feed waste.” |

| Thandi Ndlovu |

Agri-Cooperative Director |

Cattle Farming |

12 years |

“Handles our drought-resistant grass perfectly—no clogging even at 50°C.” |

| Pieter Botha |

Biomass Energy Consultant |

Renewable Energy |

20 years |

“1.3 g/cm³ pellet density meets EU standards for export-grade biofuel.” |

| Anika De Beer |

Aquaculture Nutritionist |

Fish Feed |

8 years |

“Floating pellets maintain shape for 6+ hours in water, improving feed conversion.” |

| Elias Mthembu |

USDA-Certified Organic Farmer |

Organic Fertilizer |

10 years |

“Sanitizes poultry litter pellets at 80°C, passing safety tests consistently.” |

| Leah Koen |

Feed Mill Engineer |

Industrial Production |

18 years |

“200-ton die lifespan exceeds competitors by 30%; ROI in 8 months.” |

| Willem Pretorius |

Livestock Veterinarian |

Animal Health |

14 years |

“Low-heat pelleting preserves probiotics in sheep feed—critical for gut health.” |

| Sara van der Merwe |

Agricultural Economist |

Smallholder Farms |

9 years |

“220V model cut energy costs by 25% for rural farmers vs. diesel alternatives.” |

| Tobias Fischer |

Industrial Boiler Specialist |

Manufacturing |

22 years |

“Rice husk pellets from Maikong mill have <0.2% sulfur—cleaner than coal.” |

| Nomsa Khumalo |

NGO Project Leader |

Disaster Relief |

7 years |

“Mobile unit processes flood-damaged crops into emergency feed within hours.” |

Pellet Making Machine Price Comparison (Global & South Africa)

| Product Name |

Model |

Company |

Price Range (USD) |

Key Advantages |

Limitations |

| RICHI Cattle Feed Line |

SZLH420 |

RICHI MACHINERY |

$440,000 (10t/h) |

Full automation, 3-8mm pellet customization |

High upfront cost |

| KX-MACHINERY Wood Pellet |

Custom |

KX-MACHINERY |

15,000−15,000−50,000 |

Energy-saving, 600-800kg/h output |

Requires 380V power |

| LANE Goat Feed |

GT260 |

LANE |

8,000−8,000−12,000 |

Compact, 400-500kg/h, 15kW power |

Limited to small-scale farming |

| YULONG Biomass |

XGJ560 |

YULONG |

25,000−25,000−35,000 |

Double-layer die, 1-1.5t/h capacity |

Needs skilled operators |

| CPM Master Pellet Mill |

7700 Series |

CPM |

120,000−120,000−200,000 |

Industrial-grade, high durability |

Complex maintenance |

| SmallPelletMachine |

ZLSP-D 200B |

SmallPelletMachines |

3,000−3,000−5,000 |

80-120kg/h, 7.5kW, portable |

Low output for commercial use |

| Buskirk PM810 |

PM810 |

Buskirk Engineering |

18,000−18,000−25,000 |

Low RPM/high torque, reduces volume by 65% |

Manual feed system |

| PelletMasters |

15HP Diesel |

PelletMasters |

12,000−12,000−15,000 |

PTO/diesel options, mobile |

Not pre-wired for power receptacles |

| AKAHL Eco Roll |

65-1500 |

AMANDUS KAHL |

150,000−150,000−300,000 |

25% energy savings, DISTAMAT automation |

Premium pricing |

| Gemco Ring Die |

MZLH420 |

Gemco Energy |

50,000−50,000−80,000 |

1-3t/h, ENplus-certified |

Requires CHP plant integration |

Maikong Pellet Machine Price Range in South Africa

| Product Name |

Model |

Price Range (ZAR) |

Key Features |

Ideal For |

| Maikong Farm Pro |

MK-FP200 |

R150,000-R250,000 |

200-300kg/h, 7.5kW, handles grass/straw |

Smallholder farms & cooperatives |

| Maikong Industrial |

MK-IND500 |

R500,000-R800,000 |

500-700kg/h, 22kW, automated moisture control |

Feed mills & biomass plants |

| Maikong Mobile |

MK-MB100 |

R300,000-R450,000 |

PTO/diesel, 100kg/h, no grid dependency |

Remote farms & disaster relief |

| Maikong Eco |

MK-ECO300 |

R400,000-R600,000 |

Solar-compatible, 300kg/h, low maintenance |

Eco-friendly projects |

Ultimate Guide to Maikong Pellet Machine Technology in South Africa: Why We Lead the Market

Contact Us to Become Maikong Pellet Machine Distributor in South Africa & Nigeria

Why Partner With Our Facetory?

We invite passionate entrepreneurs across South Africa and Nigeria to join our distributor network. Our pellet machines dominate African markets through three unmatched advantages:

-

Localized Support

- Dedicated WhatsApp lines for real-time technical assistance in English, Afrikaans, and local dialects

- On-site training programs at our Johannesburg facility

-

Market-Leading Technology

- Machines adapted for load-shedding conditions (hybrid diesel/PTO models)

- SANAS-certified pellet quality meeting EU export standards

-

Profit Protection

- Exclusive territorial rights for authorized distributors

- 15% higher profit margins than competitors through direct factory pricing

Interested partners should contact Mrs Lucy or Mr Mark via preferred channels. We respond to all inquiries within 2 business hours with:

- Customized distributor pricing tiers

- Marketing collateral templates

- Local certification documentation

Let us build sustainable agribusiness solutions together across Africa!

Pellet Machine Technical Specifications

| Category |

Specification |

Details |

| Basic Attributes |

Product Name |

Maikong Animal Feed Pellet Machine |

|

Condition |

Brand New |

|

Weight |

75 kg |

|

Warranty |

1 Year Comprehensive Warranty |

|

Place of Origin |

Maikong Factory, South Africa |

| Power Specifications |

Voltage Options |

220V/380V Dual Voltage System |

|

Motor Type |

Maikong Premium Efficiency Motor |

| Physical Dimensions |

Dimensions (L×W×H) |

870×230×730mm Compact Design |

| Production Capacity |

Hourly Output |

80-100kg/h Consistent Performance |

| Material Construction |

Machine Body Material |

High-Grade Alloy Steel |

|

Die Material |

Hardened Alloy Steel |

| Functional Features |

Key Selling Points |

High Productivity & Low Operating Cost |

|

Processing Type |

Livestock Feed Plant Solution |

|

Driven Method |

Electric Energy Efficient Operation |

| Material Handling |

Raw Material Compatibility |

Wheat Bran & Various Grains |

| Customization Options |

Color Options |

Custom Colors Available |

| Application Scope |

Primary Usage |

Animal Poultry Livestock Pellet Production |

| Performance Features |

Operational Characteristics |

High Efficiency with Minimal Waste |

Our Maikong pellet machines incorporate several industry-leading features:

- Robust alloy steel construction ensures durability in African farming conditions

- Dual voltage system accommodates various power supply situations

- Compact footprint saves valuable workspace while maintaining high output

- Custom color options allow for brand personalization

- Specially hardened dies provide extended service life

We maintain strict quality control throughout our manufacturing process in South Africa to deliver reliable pellet machines that meet local farming needs. Our 1-year warranty covers all major components, giving customers peace of mind with their investment.

The 80-100kg/h capacity makes this unit ideal for small to medium-scale operations looking to produce quality feed pellets efficiently. Our machines handle various raw materials including wheat bran and other common feed ingredients.

Jpeg

Jpeg