South Africa Top pellet machine, animal feed pellet machine Manufacturer

Key Benefits of MAIKONG Fish Feed Pellet Machine

Superior Feed Quality

- Produces uniform pellets that maintain integrity in water

- Adjustable density for perfect floating or sinking properties

- Enhanced nutrient preservation through controlled processing

- Improved digestibility reducing water pollution

Operational Excellence

- Energy-efficient design reduces production costs

- Durable components ensure minimal maintenance

- Simple operation with comprehensive training

- Versatile processing of various raw materials

Ready to Optimize Your Fish Feed Production?

Our technical team is available to discuss your specific requirements and provide a customized solution.

Fish Feed Pellet Machine Video

Technical Specifications of MAIKONG Fish Feed Pellet Machine

Our fish feed pellet machines are engineered for precision, reliability, and efficiency. Each model is built with premium components and undergoes rigorous quality testing before shipment.

| Model | Screw Diameter | Capacity (kg/h) | Main Power | Feeding Power | Cutting Power | Dimensions (mm) | Weight (kg) |

| MK-BEM40 | φ40mm | 30-40 | 5.5kw | 0.4kw | 0.4kw | 1400×1100×880 | 310 |

| MK-BEM50 | φ50mm | 60-80 | 11kw | 0.4kw | 0.4kw | 1450×1120×900 | 360 |

| MK-BEM70 | φ70mm | 180-250 | 18.5kw | 0.4kw | 0.4kw | 1500×1320×950 | 640 |

| MK-BEM90 | φ90mm | 400-450 | 30kw | 0.6kw | 1.5kw | 2300×1640×1000 | 950 |

Additional models available upon request. Contact us for the complete catalog.

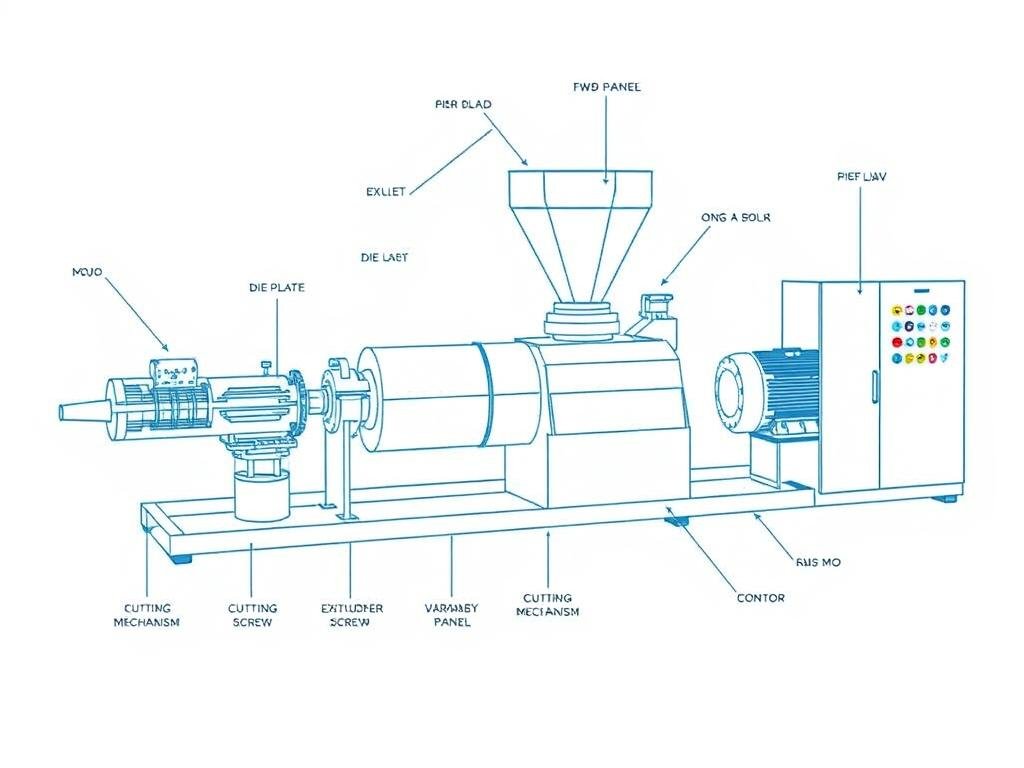

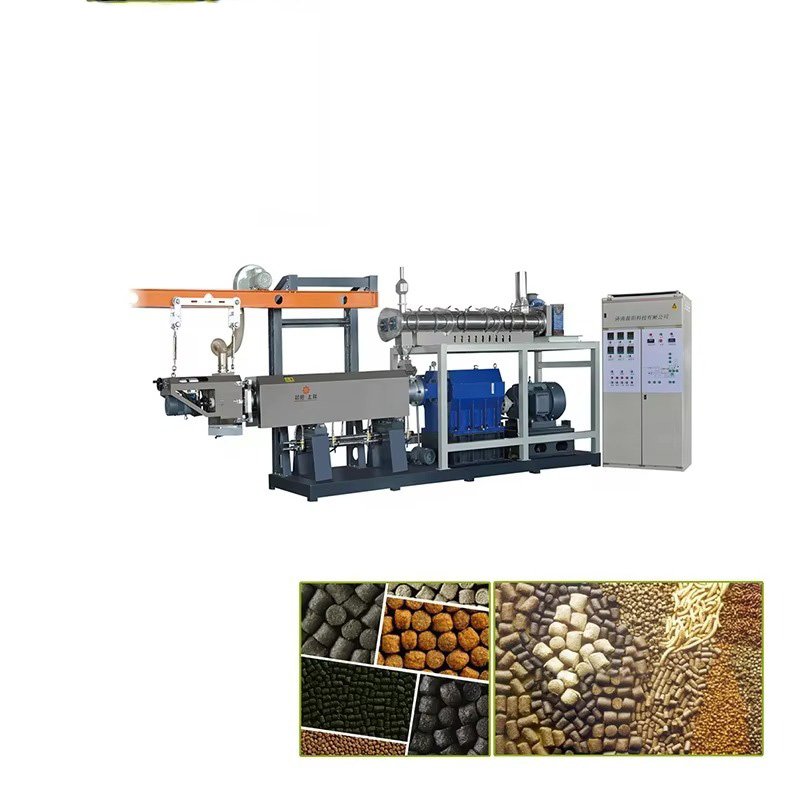

Fish Feed Pellet Machine Structure and Components

Feeding System

Our precision feeding system ensures uniform and stable material flow, with electromagnetic speed control or frequency converter to adjust feeding quantity based on extrusion motor load.

Extrusion Chamber

The heart of the fish feed pellet machine, featuring segmented screw and barrel design for adjustable compression to meet different feed requirements and expansion characteristics.

Cutting Mechanism

Precision rotary cutters ensure uniform pellet length, with adjustable speed control to customize pellet size according to fish species and growth stage requirements.

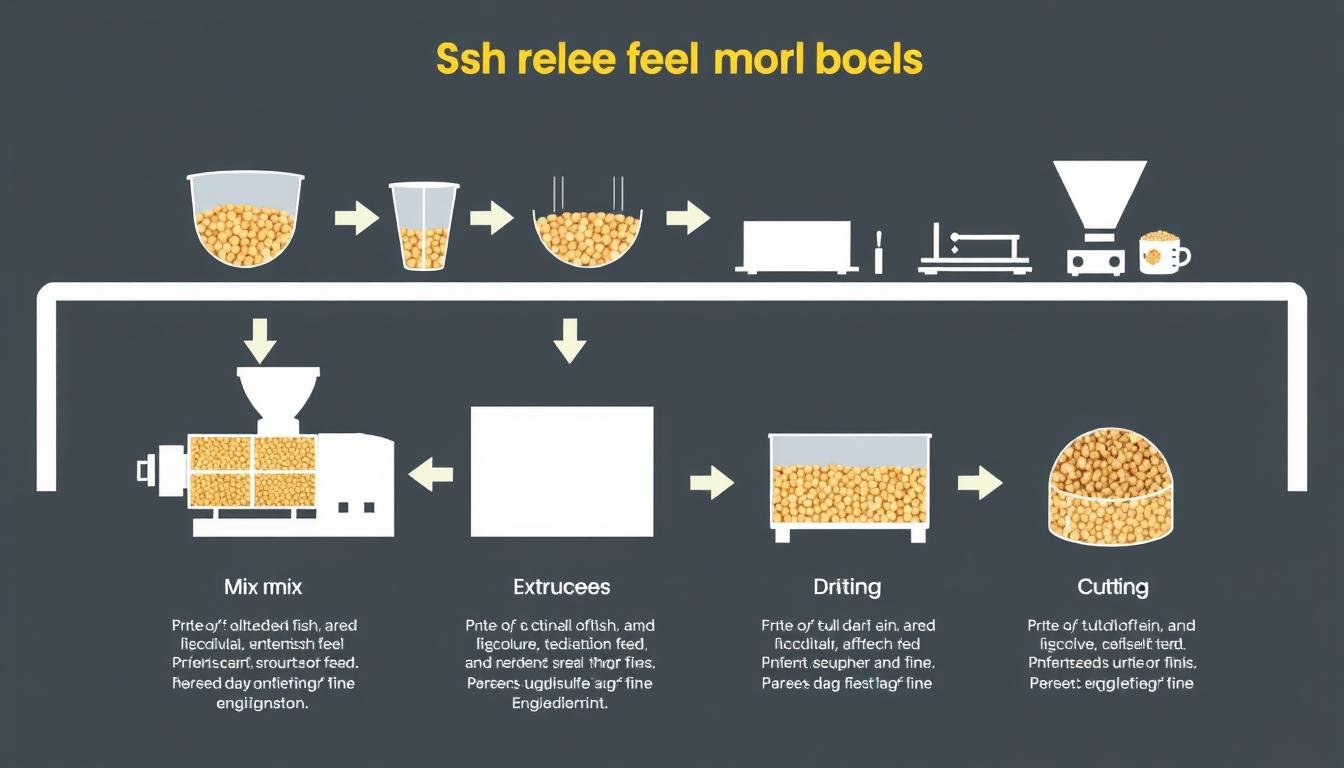

How Our Fish Feed Pellet Machine Works

- Material Feeding: Raw materials enter the extrusion chamber through the controlled feeding system.

- Compression: As materials move through the gradually narrowing chamber, pressure increases while creating friction and heat.

- Gelatinization: Starch components gelatinize under heat and pressure, creating a binding matrix.

- Extrusion: The material is forced through die holes at 3.0-10MPa pressure and 120-150°C temperature.

- Expansion: Upon exiting to atmospheric pressure, rapid moisture evaporation causes expansion.

- Cutting: Rotary cutters slice the extruded material into uniform pellets.

- Cooling: Pellets cool and solidify, locking in their expanded structure.

Need Technical Guidance?

Our engineers can help you select the right model and configuration for your specific fish species and production requirements.

Applications and Feed Types

Fish Species Compatibility

Freshwater Fish

- Tilapia

- Catfish

- Carp

- Trout

Marine Fish

- Sea Bream

- Sea Bass

- Grouper

- Snapper

Crustaceans

- Shrimp

- Crayfish

- Crabs

- Lobsters

Feed Pellet Types

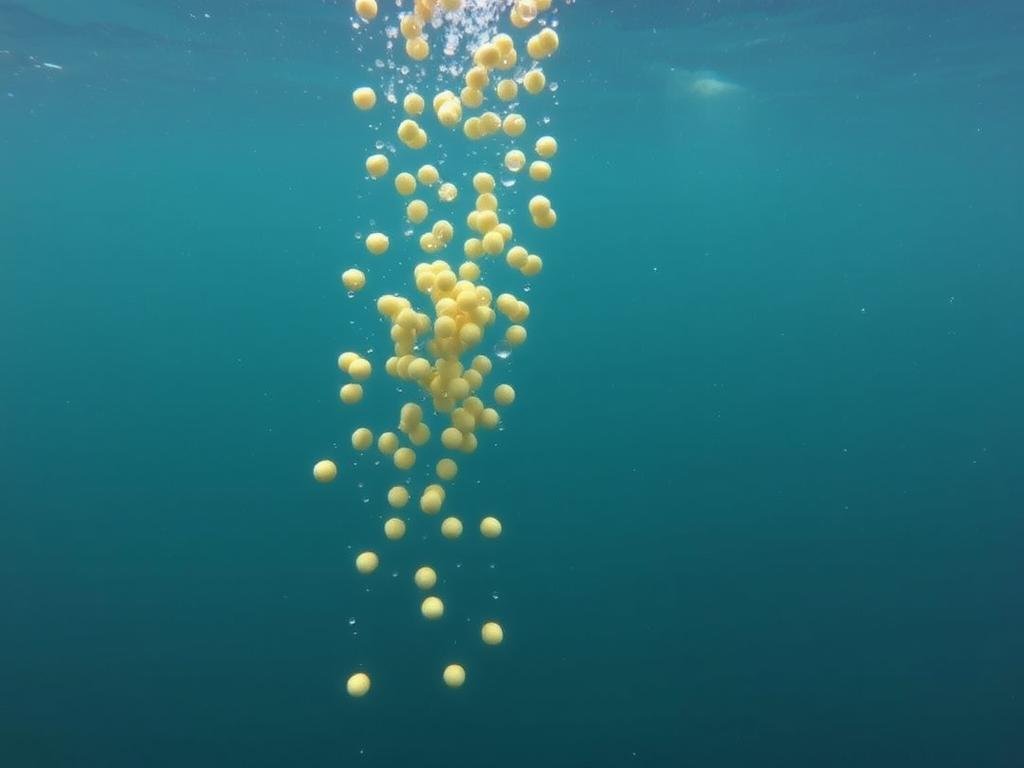

Floating Feed Pellets

Our fish feed pellet machine produces high-quality floating pellets that remain on the water surface for extended periods. This allows for easy monitoring of feeding activity and prevents waste accumulation at the pond bottom.

Sinking Feed Pellets

For bottom-feeding species, our machines produce dense, sinking pellets that quickly descend to the pond bottom while maintaining their structural integrity and nutritional value.

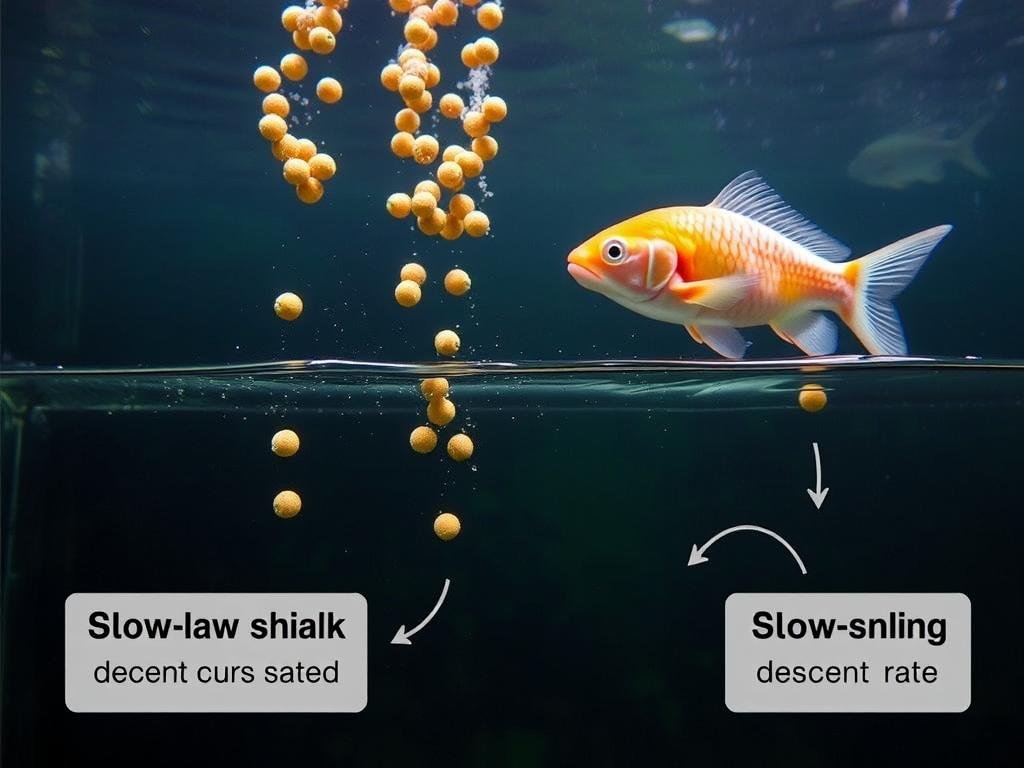

Slow-Sinking Feed Pellets

Our advanced extrusion technology allows for the production of slow-sinking pellets with controlled descent rates, ideal for mid-water feeding species and mixed aquaculture environments.

Micro Pellets for Fry

Specialized micro-pellet production capabilities for fish fry and fingerlings, with pellet sizes as small as 0.8mm while maintaining nutritional integrity and appropriate density.

Advantages of MAIKONG Fish Feed Pellet Machine

Why Choose MAIKONG

- Premium Manufacturing: Built in our state-of-the-art facility in SZ, GD, China with stringent quality control

- Superior Supply Chain: Access to China’s best component suppliers for reliability and performance

- Customization Options: Machines tailored to your specific production requirements

- Technical Support: Real-time WhatsApp technical assistance and troubleshooting

- Competitive Pricing: Factory-direct pricing without middlemen markups

- Comprehensive Training: Detailed operation and maintenance guidance

- Spare Parts Availability: Quick access to replacement components

Enhanced Feed Quality and Farm Profitability

Improved Feed Conversion Ratio

The extrusion process significantly improves feed digestibility, resulting in better feed conversion ratios (FCR) and faster fish growth. Studies show up to 15-20% improvement in FCR compared to traditional feed methods.

Reduced Feed Waste

The uniform size and improved water stability of pellets produced by our fish feed pellet machine significantly reduce feed waste, lowering production costs and minimizing water pollution in aquaculture systems.

Ready to Boost Your Aquaculture Productivity?

Contact us today to discuss how MAIKONG fish feed pellet machines can transform your fish farming operation.

Compatible Raw Materials

Our fish feed pellet machines are designed to process a wide variety of raw materials, allowing for flexible formulation based on local availability and cost considerations.

Protein Sources

- Fish meal

- Soybean meal

- Blood meal

- Feather meal

- Insect protein

Carbohydrate Sources

- Corn/Maize

- Wheat

- Rice bran

- Cassava

- Sorghum

Additives

- Vitamins

- Minerals

- Binders

- Pigments

- Probiotics

Manual Fish Feed Pellet Machine Options

For small-scale fish farmers and operations in areas with limited electricity access, MAIKONG offers manual fish feed pellet machine options that deliver quality results with human-powered operation.

MK-Manual Series Features

- Hand-crank operation with efficient gear system

- Production capacity of 5-15kg per hour

- Adjustable pellet diameter from 2-6mm

- Durable cast iron and stainless steel construction

- Easy cleaning and maintenance

- Portable design for flexible placement

Ideal Applications

- Small-scale fish farms

- Research facilities requiring small batches

- Remote locations without reliable electricity

- Backup production during power outages

- Training and educational purposes

- Test formulations before scaling up

Fish Feed Pellet Machine Price Considerations

The fish feed pellet machine price varies based on several factors including capacity, features, and customization requirements. While we offer competitive factory-direct pricing, it’s important to understand what influences the final investment.

| Price Factor | Description | Impact on Price |

| Production Capacity | From 30kg/h to 2000kg/h | Higher capacity = Higher price |

| Die Material | Stainless steel vs. carbon steel | Stainless steel adds 15-20% |

| Control System | Manual, semi-automatic, or fully automatic | Automation adds 20-30% |

| Customization | Special features or configurations | Varies by requirements |

| Warranty | Standard 1-year vs. extended options | Extended adds 5-10% |

International Price Benchmarks

While our machines are competitively priced globally, we understand that different markets have different expectations. For reference, the fish feed pellet machine price in India typically ranges from ₹300,000 to ₹1,500,000 depending on capacity and features. Our direct factory pricing often provides significant savings compared to these benchmarks.

“Investing in a quality fish feed pellet machine is not just about the initial purchase price, but about the total cost of ownership including energy efficiency, maintenance requirements, and production consistency.”

Get Your Personalized Quotation

Contact us with your specific requirements for a detailed price quote tailored to your needs.

Frequently Asked Questions

What raw materials can be processed in your fish feed pellet machine?

Our machines can process a wide variety of raw materials including corn/maize, soybean meal, fish meal, wheat bran, rice bran, blood meal, feather meal, vitamins, minerals, and binders. The flexible design accommodates different formulations based on local availability and target fish species requirements.

What certifications do your fish feed pellet machines have?

MAIKONG fish feed pellet machines are certified with ISO9001-2000, CE Certification, and SGS Certification. These certifications ensure our equipment meets international quality and safety standards, providing peace of mind for our customers worldwide.

What is the minimum capacity fish feed pellet machine you offer?

Our smallest electric model is the MK-BEM40 with a capacity of 30-40kg/h. For even smaller operations, we offer manual fish feed pellet machines with capacities of 5-15kg/h, ideal for small-scale fish farms or research facilities.

How long is the delivery time for your machines?

Standard fish feed pellet machines typically ship within 10-30 working days after order confirmation. Customized machines may require 30-45 working days. Complete feed production lines can take 30-90 days depending on complexity. We work with reliable freight forwarders to ensure timely delivery to South Africa.

What payment terms do you offer?

We typically require 40% deposit by T/T within 7 working days after contract signing, with the remaining 60% payable before shipment. We also accept L/C for the balance payment. We’re flexible and can negotiate specific payment terms based on your requirements and order size.

Do you provide installation and training services?

Yes, we offer comprehensive installation guidance, operator training, and ongoing technical support. For larger installations, we can arrange for our technicians to visit your facility (additional charges may apply). We also provide detailed manuals and video tutorials for all our machines.

Have More Questions?

Our technical team is ready to assist with any inquiries about our fish feed pellet machines.

Why Choose MAIKONG for Your Fish Feed Production Needs

With nearly three decades of experience in manufacturing premium feed processing equipment, MAIKONG has established itself as a trusted partner for aquaculture businesses across South Africa and beyond. Our commitment to quality, innovation, and customer support ensures that your investment in a fish feed pellet machine delivers maximum return through improved feed quality, reduced waste, and enhanced fish growth.

Ready to Transform Your Fish Feed Production?

Contact MAIKONG today to discuss your specific requirements and discover how our fish feed pellet machines can boost your aquaculture productivity.