South Africa Top pellet machine, animal feed pellet machine Manufacturer

MAIKONG: Premium Chinese Manufacturer of Dog Food Processing Equipment

Based in SZ, GD province, MAIKONG has established itself as a leading manufacturer of high-performance dog feed pellet machines and complete pet food production lines. Our state-of-the-art manufacturing facilities and superior supply chain capabilities allow us to produce both premium and cost-effective equipment for the South African market.

Manufacturing Excellence

- Advanced production facilities with precision engineering

- Rigorous quality control at every manufacturing stage

- Industry-leading components from trusted suppliers

- ISO9001, CE, and SGS certified manufacturing processes

South African Market Focus

- Equipment designed for South African power specifications

- Machines optimized for local raw materials

- Dedicated WhatsApp technical support for South African clients

- Competitive pricing with excellent ROI for local businesses

Ready to Upgrade Your Dog Food Production?

Our technical team is available to discuss your specific requirements and recommend the ideal machine configuration.

MK-SZLH Series Dog Food Pellet Machine Specifications

Our comprehensive range of dog food pellet machines offers solutions for operations of all sizes. From small-scale production to industrial manufacturing, we have the perfect model to meet your specific requirements.

| Model | Output (t/h) | Main Motor (kW) | Feeder Power (kW) | Conditioner Power (kW) | Ring Die Diameter (mm) |

| MK-SZLH250 | 1~1.5 | 22 | 1.1 | 1.5 | 250 |

| MK-SZLH320 | 3~4 | 37 | 1.5 | 2.2 | 320 |

| MK-SZLH350 | 5~6 | 55 | 1.5 | 3.0 | 350 |

| MK-SZLH420 | 10~12 | 110 | 1.5 | 7.5 | 420 |

| MK-SZLH508 | 15~16 | 160 | 2.2 | 11 | 508 |

| MK-SZLH558 | 20~22 | 185 | 2.2 | 11 | 558 |

Standard Equipment Configuration

- Ring die material: Premium stainless steel

- Door cover: 6mm SUS304 stainless steel

- Feed chute: 3mm SUS304 stainless steel

- Gear box: HT250 high-strength

- Gear: 42CrMo hardened steel

- Gear shaft: 20CrMnTi precision-machined

- Spindle: 42CrMo wear-resistant

- Bearings: Imported premium quality

- Overload protection: Safety pin system

- Motor: Siemens high-efficiency

All dog pellet machines for sale in South Africa include a standard 1-year warranty with options for extended coverage. We maintain a comprehensive stock of spare parts in South Africa for quick replacement when needed.

Key Technical Features of MAIKONG Dog Food Pellet Machines

Advanced Gear Transmission

Our gear transmission system delivers 15% higher output than belt-driven alternatives. High-precision aviation-grade gear grinding ensures smooth operation and significantly reduced noise levels.

Customizable Ring Dies

Choose from various apertures between φ1.5 and φ12mm to achieve optimal pellet size and density for different dog breeds and nutritional requirements.

Premium Siemens Motors

All machines feature reliable Siemens motors for consistent performance, low power consumption, and reduced maintenance requirements even in demanding production environments.

Food-Grade Stainless Steel

Critical components including the feeding auger, conditioner, and door cover are constructed from SUS304 stainless steel to prevent contamination and ensure a longer service life.

Precision Cutting System

Dual-blade cutting mechanism allows precise control over pellet length, ensuring consistent product size for improved packaging efficiency and product presentation.

Variable Frequency Feeding

Stepless frequency conversion motor provides precise control over material flow rate, ensuring optimal conditioning and consistent pellet quality throughout production runs.

Need Technical Specifications?

Our engineering team can provide detailed technical drawings and specifications for your specific production requirements.

Transparent Pricing for Dog Food Pellet Machines

MAIKONG offers competitive pricing on all dog food pellet machines with transparent quotations that detail all components and services included. Our standard pricing range for individual machines is FOB $7,000-100,000 USD depending on model and specifications.

Factors Affecting Machine Pricing

Technical Specifications

- Production capacity (larger output = higher price)

- Ring die specifications (material and aperture size)

- Motor power and brand selection

- Control system complexity (manual vs. automated)

Additional Considerations

- Customization requirements for specific formulas

- Energy-saving design features

- After-sales service package selection

- Shipping and installation requirements

South African Advantage: All prices include documentation for South African customs clearance, and we handle all export requirements. Our machines are designed to operate on South African power standards without additional conversion equipment.

Get Your Customized Quote Today

Tell us about your production requirements, and we’ll provide a detailed quotation with all costs clearly outlined.

Why Processed Dog Food Pellets Are Essential

Nutritional Benefits

- Precise Nutrition: Pelletized dog food allows exact formulation of proteins, fats, vitamins, and minerals for different dog breeds and life stages

- Improved Digestibility: The extrusion process increases nutrient bioavailability by up to 30% compared to raw ingredients

- Consistent Quality: Every pellet contains the same nutritional profile, eliminating selective eating behaviors

Business Advantages

- Extended Shelf Life: Properly processed pellets remain fresh for 12-18 months when properly packaged

- Reduced Waste: Pelletized feed results in 15-20% less waste compared to meal or raw diets

- Cost-Effective Ingredients: Process alternative protein sources and by-products into nutritious dog food

Dog Food Pellet Applications

Retail Pet Food

Create branded premium dog food products for retail distribution with custom shapes, sizes, and nutritional profiles.

Commercial Kennels

Produce cost-effective, nutritionally balanced feed for commercial breeding operations and boarding facilities.

Specialty Formulations

Develop therapeutic and specialized diets for veterinary clinics and animals with specific health requirements.

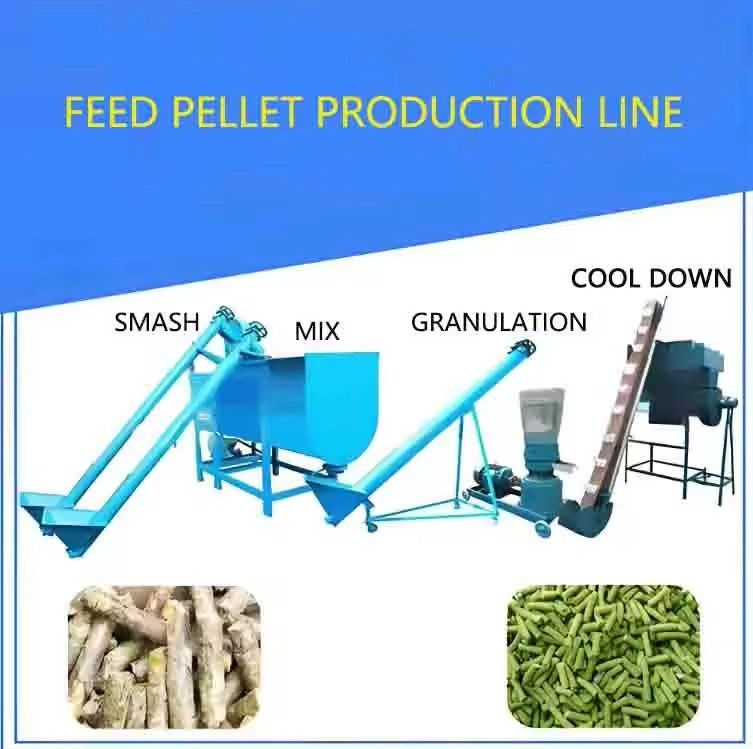

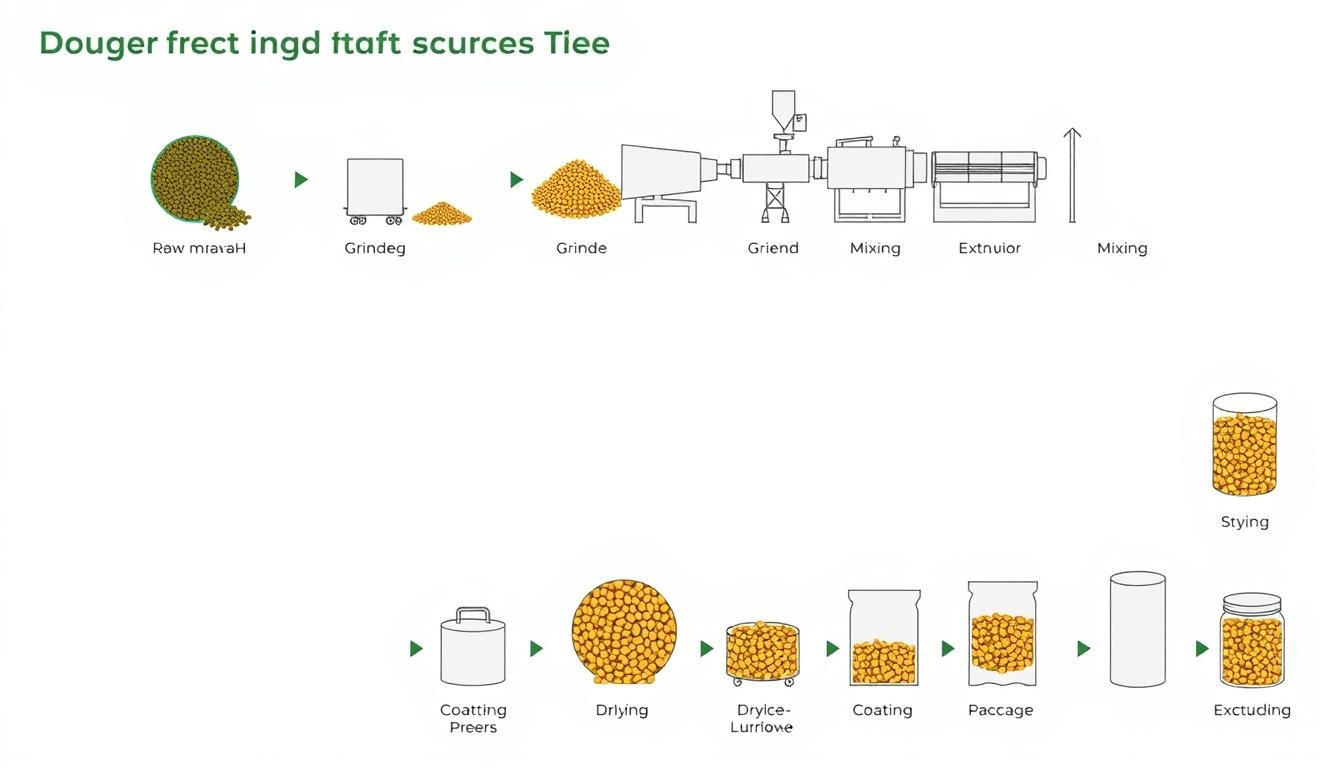

Dog Food Pellet Production Process

Understanding the complete manufacturing process helps you select the right dog food pellet making machine for your specific production requirements.

- Raw Material PreparationIngredients including grains, meat meals, and supplements are inspected, cleaned, and prepared for processing.

- GrindingMaterials are ground to a uniform particle size (typically 60-80 mesh) using hammer mills for optimal mixing and extrusion.

- MixingPrecise batching and mixing of dry ingredients with careful addition of fats, oils, and liquid additives.

- ConditioningThe mixture is pre-conditioned with steam to achieve 20-25% moisture content and optimal temperature.

- Extrusion/PelletingThe conditioned mixture passes through the dog food pellet machine where it’s compressed through the die to form pellets.

- Drying/CoolingFresh pellets are dried to 8-10% moisture content and cooled to ambient temperature for stability.

- CoatingOptional application of palatability enhancers, fats, or protective coatings to improve taste and shelf life.

- PackagingFinal product is screened for quality and packaged in appropriate containers for distribution.

Need a Complete Production Line?

MAIKONG offers turnkey dog food production lines with all necessary equipment from raw material handling to packaging.

Frequently Asked Questions About Dog Food Pellet Machines

What raw materials can be processed with your dog food pellet machines?

Our dog feed pellet machines can process a wide variety of ingredients including corn/maize, wheat, rice, various flours, meat meals (chicken, fish, etc.), bone meal, soybean meal, vitamins, and minerals. The raw materials should ideally be ground to 60-80 mesh size for optimal processing.

What is the minimum capacity dog food pellet machine available?

Our smallest model, the MK-SZLH250, produces 1-1.5 tons per hour, making it suitable for small to medium operations. For smaller production needs, we can recommend alternative solutions based on your specific requirements.

What payment terms do you offer for South African buyers?

We offer flexible payment options including:

- 40% deposit by T/T with 60% balance before shipping

- 40% deposit by T/T with 60% balance by L/C

- Custom payment terms for established businesses

All transactions can be conducted in USD with secure payment processing.

How long is the delivery time to South Africa?

Standard machines typically ship within 10-30 working days after order confirmation. Custom machines may require 30-45 days. Shipping to South Africa generally takes 25-35 days by sea freight. We work with reliable freight forwarders to ensure smooth customs clearance.

Do you provide installation and training services in South Africa?

Yes, we offer comprehensive installation, commissioning, and operator training services throughout South Africa. Our technicians can travel to your facility to ensure proper setup and operation. We also provide remote technical support via WhatsApp for immediate assistance when needed.

What certifications do your dog food pellet machines have?

All MAIKONG dog pellet machines are manufactured under ISO9001-2000 quality management systems and carry CE certification for safety. Our machines comply with international food processing equipment standards and South African regulatory requirements.

Contact MAIKONG for Your Dog Food Pellet Machine

Technical Support and Sales

Our dedicated team is ready to assist with technical questions, customization requests, and pricing information for all dog food pellet making machines.

- WhatsApp: +86 13510907401

- Email: Lucy@pelletmachine.co.za

- Website: https://pelletmachine.co.za

Ready to Upgrade Your Production?

Contact us today to discuss your specific requirements and receive a customized quotation for the perfect dog food pellet machine solution.

Why Choose MAIKONG for Your Dog Food Pellet Machine

With decades of manufacturing experience, superior technical support, and a deep understanding of South African market needs, MAIKONG is your ideal partner for dog food pellet making equipment. Our machines combine reliability, efficiency, and value to help your business succeed in the competitive pet food industry.

From initial consultation through installation and ongoing support, we’re committed to your complete satisfaction. Contact us today to discover how our dog food pellet machines can transform your production capabilities and drive your business forward.