South Africa Top pellet machine, animal feed pellet machine Manufacturer

MAIKONG: Your Trusted Partner in Pelletizing Technology

Based in SZ, GD, China, MAIKONG has established itself as a leading manufacturer of premium food pellet machines and complete production lines. With access to China’s superior supply chain and state-of-the-art manufacturing facilities, we deliver exceptional quality equipment at competitive prices to South African businesses.

Our Manufacturing Excellence

- Advanced production facilities with precision engineering

- Rigorous quality control at every manufacturing stage

- ISO-certified production processes

- Continuous innovation in pelletizing technology

Our Commitment to You

- Customized solutions for your specific production needs

- Comprehensive technical support via WhatsApp

- Reliable after-sales service

- Competitive pricing without compromising quality

Ready to Enhance Your Production Efficiency?

Our technical team is available to discuss your specific requirements and recommend the ideal pelletizing solution.

Comprehensive Food Pellet Machine Range

MAIKONG offers a diverse selection of food pellet machines designed to meet various production requirements. From small-scale operations to industrial production lines, our equipment delivers consistent pellet quality with optimal energy efficiency.

Our Core Product Categories

Animal Feed Pellet Machines

Specialized equipment for producing nutritionally balanced feed pellets for livestock, poultry, and aquaculture.

- Cattle feed pellet machine

- Chicken feed machine

- Fish feed pellet machine

- Rabbit pellet making machine

Biomass Pellet Machines

Convert agricultural waste and biomass materials into efficient, eco-friendly fuel pellets.

- Wood pellet machine

- Lucerne pellet machine

- Biofuel pellet machine

- Straw pellet production line

Specialty Pellet Machines

Custom-designed equipment for specialized applications and unique production requirements.

- Dog food pellet making machine

- Organic fertilizer production line

- Cat litter production line

- Special pellet plant solutions

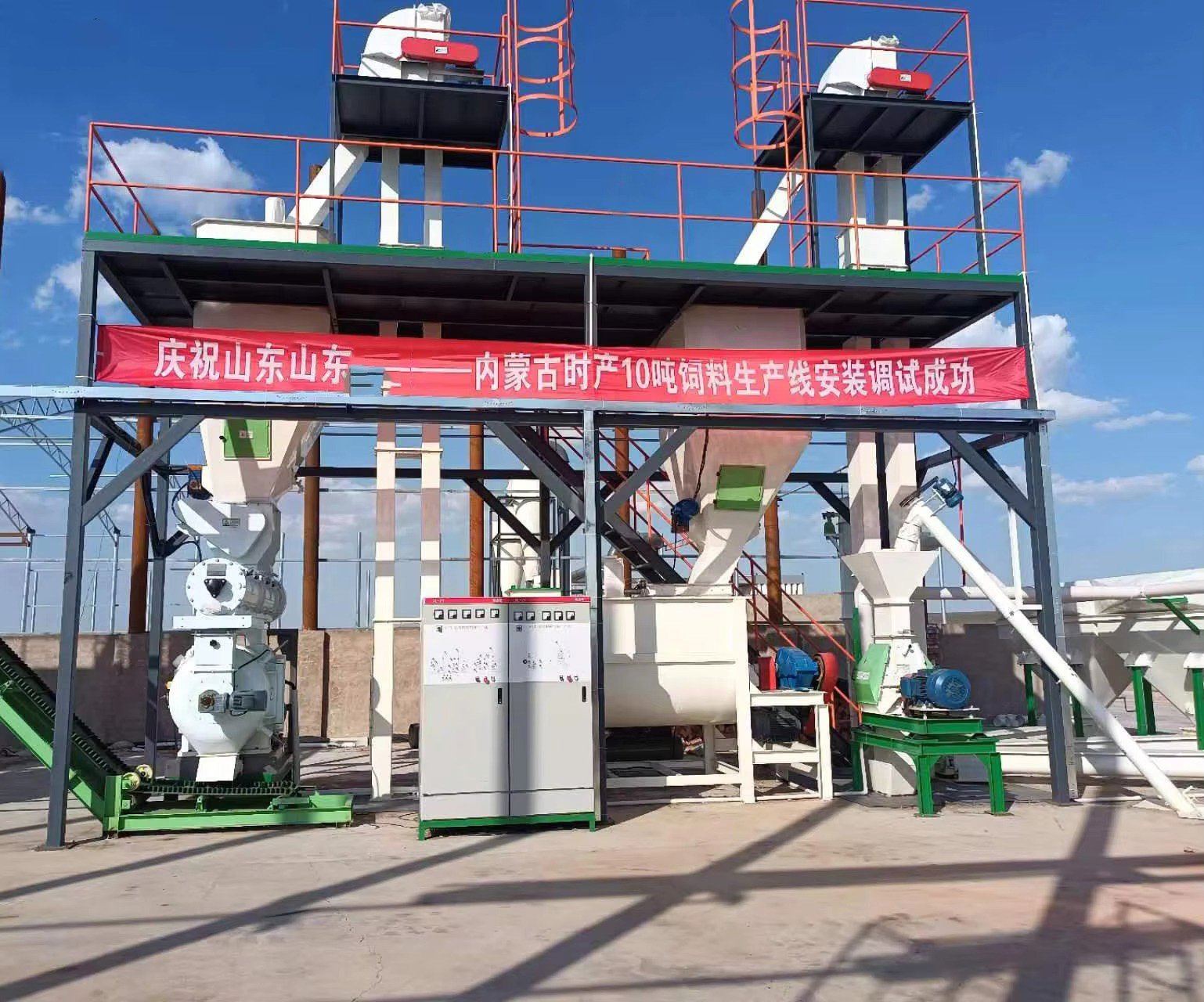

Complete Production Lines

Beyond individual machines, MAIKONG specializes in designing and implementing complete pellet production lines tailored to your specific requirements. Our turnkey solutions include:

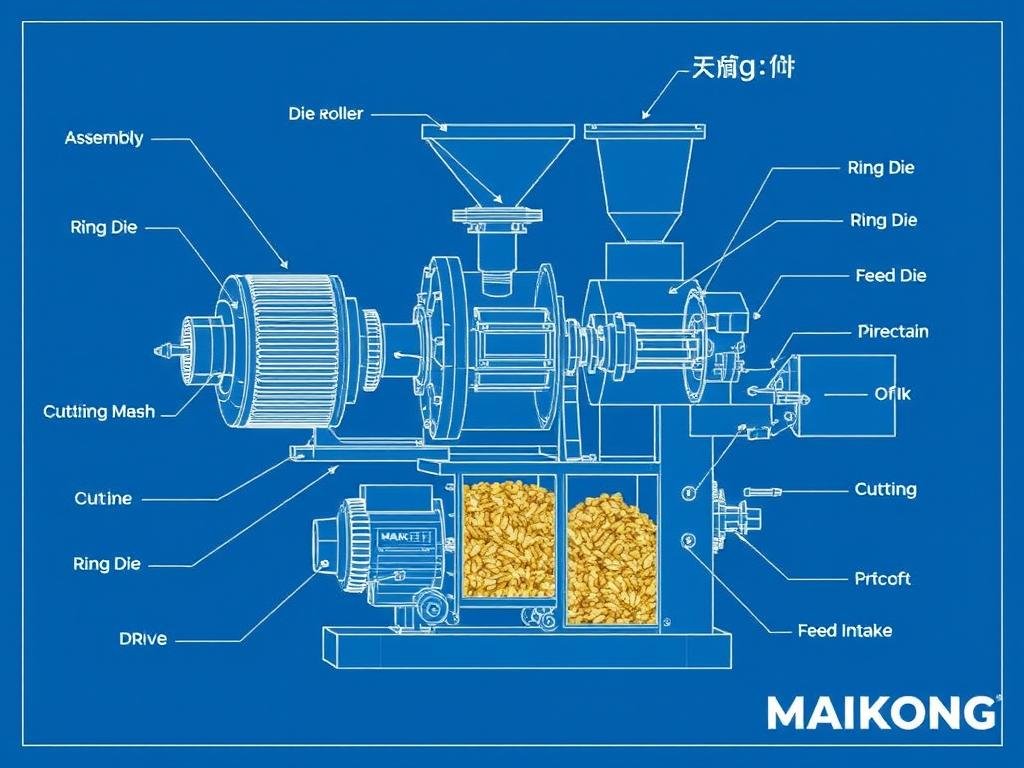

Core Equipment Components

- Crushing unit and hammer mills

- Precision mixers for uniform blending

- Ring die pelletizers (heart of the system)

- Cooling and screening systems

- Packaging machines for finished products

Supporting Systems

- Raw material cleaning screens

- Pulse dust removal systems

- Efficient conveying equipment

- Quality control stations

- Storage solutions for finished pellets

Need a Custom Production Line?

Our engineers can design a complete pellet production system optimized for your specific materials and output requirements.

Food Pellet Machine Technical Specifications

MAIKONG’s food pellet machines are available in various models to accommodate different production capacities. Below are the specifications for our most popular ring die pellet machines:

| Model | Output (t/h) | Main Motor Power (kW) | Ring Die Diameter (mm) | Pellet Diameter (mm) |

| MK-250 | 1~1.5 | 22 | 250 | 2~12 |

| MK-320 | 3~4 | 37 | 320 | 2~12 |

| MK-350 | 5~6 | 55 | 350 | 2~12 |

| MK-420 | 10~12 | 110 | 420 | 2~12 |

| MK-508 | 15~16 | 160 | 508 | 2~12 |

Key Technical Features

Ring Die Technology

Our machines feature premium stainless steel ring dies with customizable apertures (φ1.5-φ12mm) to produce pellets of various sizes according to your specific requirements.

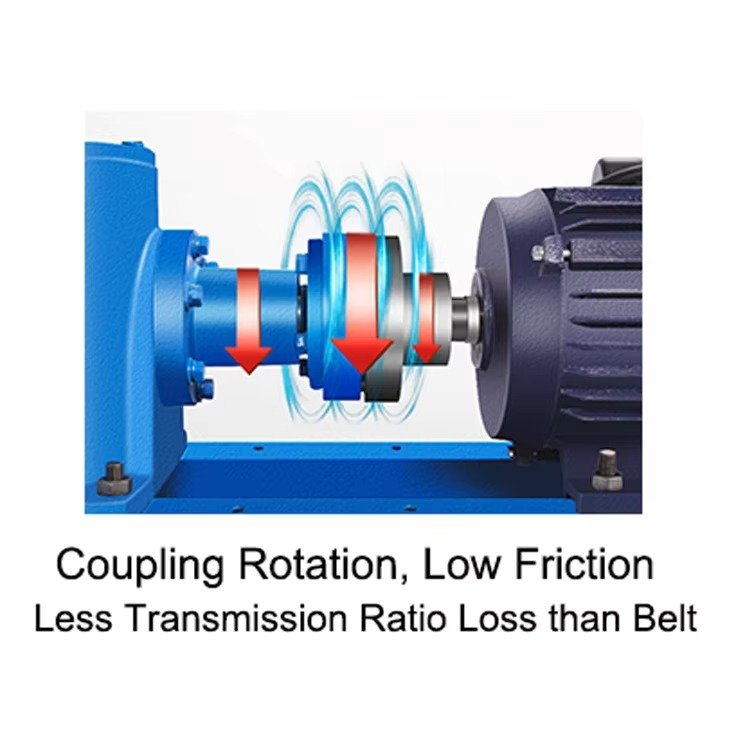

Transmission System

High-efficiency gear transmission system provides 15% higher output than belt-type alternatives, with aviation-grade gear grinding technology ensuring smooth operation and reduced noise.

Safety Features

Comprehensive safety systems including door cover travel switches, automatic motor shutdown, and overload protection through safety pins to prevent equipment damage.

Need Detailed Technical Information?

Our technical team can provide comprehensive specifications and recommend the optimal configuration for your production needs.

Global Food Pellet Machine Projects

MAIKONG has successfully implemented pellet production solutions worldwide. Here are some of our notable projects:

| Project Capacity | Country | Application |

| 3-5T/H Feed Mill | South Africa | Poultry Feed |

| 5T/H Processing Plant | Nigeria | Animal Food |

| 10-15T/H Feed Mill | Kenya | Chicken Feed |

| 5-7T/H Feed Mill Plant | Tanzania | Mixed Feed |

| 1-2T/H Pellet Plant | Zimbabwe | Chicken Feed |

Project Highlight: South African Feed Mill

One of our recent success stories involves a complete 5T/H feed mill installation in Cape Town, South Africa. This turnkey project included:

- MK-350 food pellet machine as the core component

- Complete raw material handling system

- Customized mixing and conditioning system

- Advanced cooling and packaging solution

- Full operator training and technical support

Want to See More Project Examples?

Contact us to request our detailed project portfolio or to discuss how we can implement a similar solution for your business.

Food Pellet Machine Pricing Guide

MAIKONG offers competitive pricing on all our food pellet machines and production lines. While exact costs depend on your specific requirements, the following table provides a general pricing framework:

| Scale | Total Power | Site Requirements | Installation Cycle | Estimated Cost (USD) |

| 1-2T/H | 47-75KW | 300-500m² | 7-15 Days | 10,000-50,000 |

| 3-4T/H | 53-165KW | 300-700m² | 15-20 Days | 50,000-120,000 |

| 5-7T/H | 68-259KW | 400-800m² | 20-40 Days | 70,000-250,000 |

| 8-10T/H | 125-410KW | 800-2000m² | 45-60 Days | 150,000-300,000 |

Factors Affecting Pricing

Machine Specifications

- Production capacity requirements

- Ring die specifications and material

- Motor power and brand selection

- Customization requirements

- Additional features and accessories

Project Scope

- Complete line vs. individual machine

- Installation and commissioning services

- Operator training requirements

- Spare parts package inclusion

- Warranty and service agreement terms

Request a Personalized Quote

Contact us with your specific requirements for a detailed quotation tailored to your production needs.

Frequently Asked Questions About Food Pellet Machines

What raw materials can be processed with your food pellet machines?

MAIKONG food pellet machines can process a wide variety of raw materials including corn/maize, alfalfa, wheat bran, grass, rice, beans, oil cake, and various agricultural by-products. For optimal results, larger materials should first be pulverized using our hammer mills. Our machines also allow for the addition of proteins, vitamins, minerals, and other nutritional supplements to create complete feed formulations.

What is the minimum production capacity you offer?

Our smallest standard food pellet machine has a capacity of approximately 1 ton/hour. For specialized applications such as processing grass or straw, we offer models with outputs starting from 500kg/hour. We can recommend the most appropriate model based on your specific production requirements and material types.

What certifications do your food pellet machines have?

MAIKONG food pellet machines have obtained ISO9001-2000 Certification, CE Certification, and SGS Certification. Our products meet international quality and safety standards for food processing equipment, ensuring reliable performance and compliance with regulatory requirements.

What is your typical delivery timeframe?

For standard food pellet machines, our typical delivery time is 10-30 working days. For customized machines or complete production lines, delivery times range from 30-90 days depending on the complexity and scale of the project. We work with leading freight forwarders to ensure efficient shipping to South Africa and can accommodate specific logistics requirements.

What payment terms do you offer?

Our standard payment terms include a 40% deposit upon contract signing, with the remaining 60% due before shipment. We accept T/T (wire transfer) and L/C (Letter of Credit) payment methods. We can also discuss customized payment terms for larger projects or returning customers. Please contact our sales team for specific arrangements.

Have More Questions?

Our technical team is ready to address any questions you may have about our food pellet machines and production lines.

Contact MAIKONG for Your Food Pellet Machine Needs

Get in Touch

Ready to enhance your feed production capabilities? Contact our team for expert advice, detailed quotations, or technical support for your food pellet machine requirements.

- WhatsApp: +86 135 1090 7401 (Technical Support)

- Email: Lucy@pelletmachine.co.za

- Website: https://pelletmachine.co.za

Ready to Transform Your Feed Production?

Take the first step toward optimizing your pellet production with MAIKONG’s industry-leading technology and support.