South Africa Top pellet machine, animal feed pellet machine Manufacturer

Need Expert Advice on Selecting the Right Hammer Mill?

Our technical team is ready to analyze your specific requirements and recommend the perfect solution.

MAIKONG: Leading Manufacturer of Premium Hammer Mills

Based in SZ, GD, China, MAIKONG has established itself as a premier manufacturer of industrial grinding equipment with a specialized focus on hammer mills. Our state-of-the-art manufacturing facility combines traditional craftsmanship with cutting-edge technology to produce hammer mills that exceed industry standards.

Superior Supply Chain

We’ve cultivated relationships with China’s top material suppliers and component manufacturers, ensuring every part of our hammer mill meets rigorous quality standards. This supply chain excellence allows us to maintain consistent quality while offering competitive pricing to our South African clients.

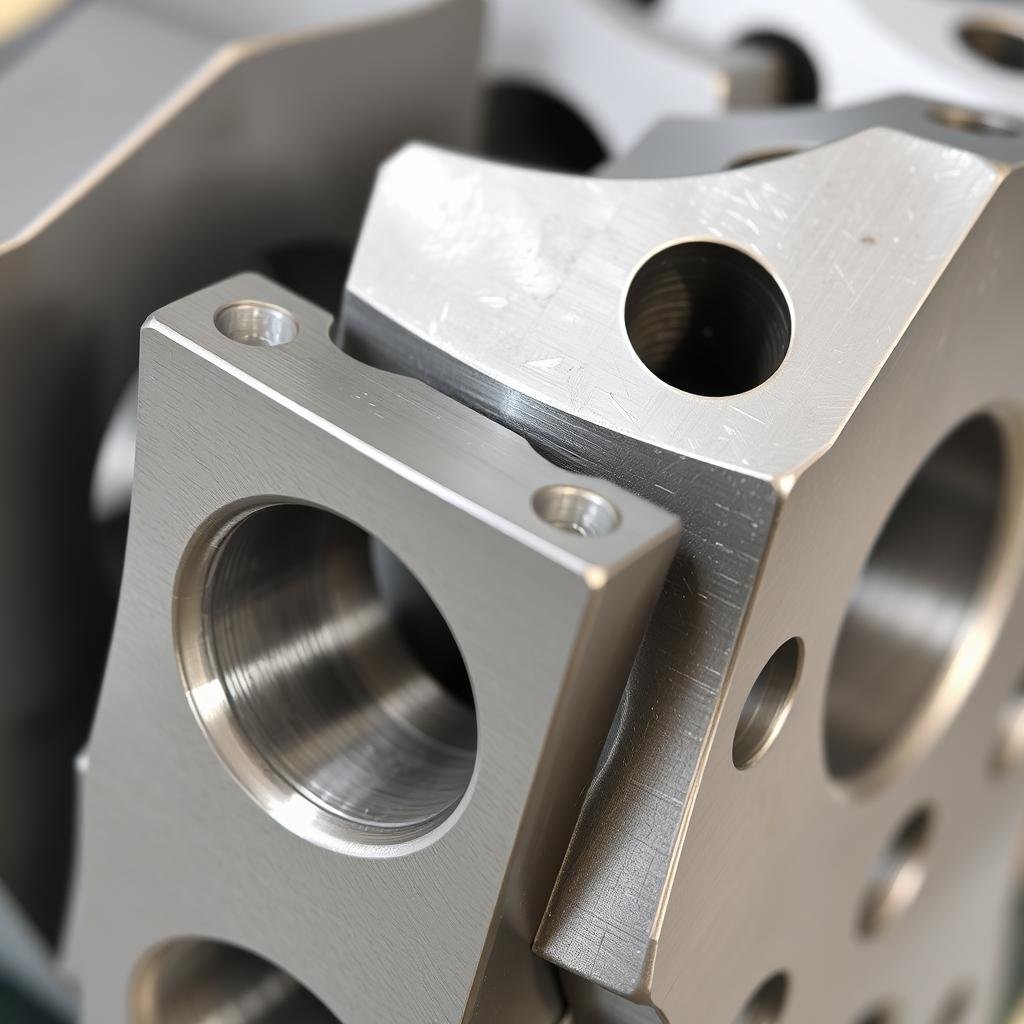

Advanced Production Capabilities

Our production facility features the latest CNC machining centers, automated welding systems, and precision testing equipment. This technological advantage translates to hammer mills with superior build quality, tighter tolerances, and exceptional reliability in demanding industrial environments.

Every hammer mill for sale undergoes rigorous quality control checks at multiple production stages. Our ISO-certified manufacturing processes ensure consistent performance and long service life, reducing your total cost of ownership and maximizing return on investment.

Versatile Applications of Our Industrial Hammer Mills

MAIKONG hammer mills are engineered to excel across diverse grinding applications, making them the preferred choice for various industries throughout South Africa.

Animal Feed Production

Our hammer mills deliver consistent particle size reduction for optimal feed conversion rates. Perfect for grinding corn, wheat, barley, and protein ingredients for livestock, poultry, and aquaculture feeds.

Biomass Processing

Efficiently reduce wood chips, agricultural residues, and other biomass materials to the optimal size for pellet production, briquetting, or direct combustion applications.

Mineral Processing

Our heavy-duty models excel at crushing and grinding various minerals, including limestone, gypsum, and clay, for construction materials, fertilizers, and industrial applications.

Not Sure Which Application Fits Your Needs?

Our technical experts can help determine the optimal hammer mill configuration for your specific materials and production requirements.

Premium Hammer Mill Models for Various Applications

MAIKONG offers a comprehensive range of hammer mill models to meet diverse grinding requirements. Each model is engineered for specific applications while maintaining our core principles of durability, efficiency, and ease of maintenance.

MK-9FQ Series: High-Efficiency Feed Grinding Hammer Mills

| Model | Capacity (t/h) | Motor Power (kW) | Rotor Speed (RPM) | Screen Size Range (mm) | Dimensions (mm) | Weight (kg) |

| MK-9FQ-40 | 1.5-2.5 | 22 | 2,900 | 0.8-8 | 1250×680×1100 | 650 |

| MK-9FQ-50 | 3-5 | 37 | 2,900 | 0.8-8 | 1450×780×1250 | 850 |

| MK-9FQ-65 | 5-8 | 55 | 2,900 | 0.8-8 | 1650×880×1350 | 1,200 |

MK-SFSP Series: Heavy-Duty Industrial Hammer Mills

| Model | Capacity (t/h) | Motor Power (kW) | Rotor Speed (RPM) | Screen Size Range (mm) | Dimensions (mm) | Weight (kg) |

| MK-SFSP56×36 | 5-8 | 55-75 | 3,600 | 1.5-12 | 1850×950×1550 | 1,800 |

| MK-SFSP66×50 | 10-15 | 90-110 | 3,600 | 1.5-12 | 2100×1150×1750 | 2,500 |

| MK-SFSP76×60 | 15-25 | 132-160 | 3,600 | 1.5-12 | 2350×1350×1950 | 3,200 |

MK-SWFL Series: Fine Grinding Hammer Mills

| Model | Capacity (t/h) | Motor Power (kW) | Rotor Speed (RPM) | Screen Size Range (mm) | Dimensions (mm) | Weight (kg) |

| MK-SWFL40 | 0.8-1.5 | 15-18.5 | 5,800 | 0.3-3 | 1150×580×980 | 480 |

| MK-SWFL50 | 1.5-3 | 22-30 | 5,800 | 0.3-3 | 1350×680×1080 | 650 |

| MK-SWFL65 | 3-5 | 37-45 | 5,800 | 0.3-3 | 1550×780×1180 | 850 |

Find Your Ideal Hammer Mill Model

Our product specialists can help you select the perfect model based on your material, capacity requirements, and budget.

Advanced Technical Features of MAIKONG Hammer Mills

Optimized Hammer Design

Our hammers are manufactured from specially formulated wear-resistant alloy steel with precision balancing. The reversible design extends service life by allowing rotation when one edge wears down. This optimized design ensures consistent grinding performance and reduces maintenance frequency.

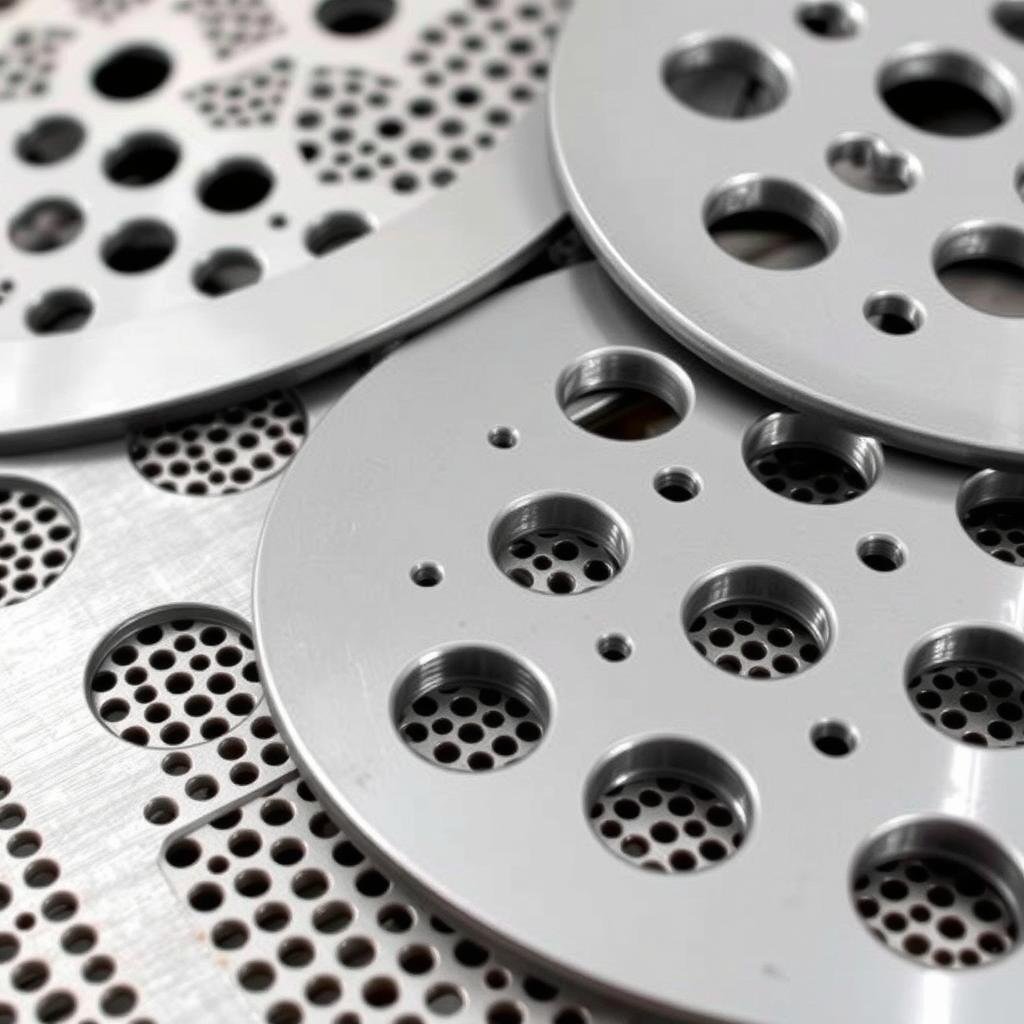

Precision Screening System

Interchangeable screens with precisely sized perforations allow for accurate control of final particle size. Our screens are manufactured from hardened steel for extended durability even when processing abrasive materials. Quick-change design minimizes downtime during screen replacement.

Advanced Feeding System

Variable-speed feeding system ensures optimal material flow into the grinding chamber, preventing overloading while maximizing throughput. The anti-bridging design eliminates material blockages, ensuring continuous operation even with difficult materials.

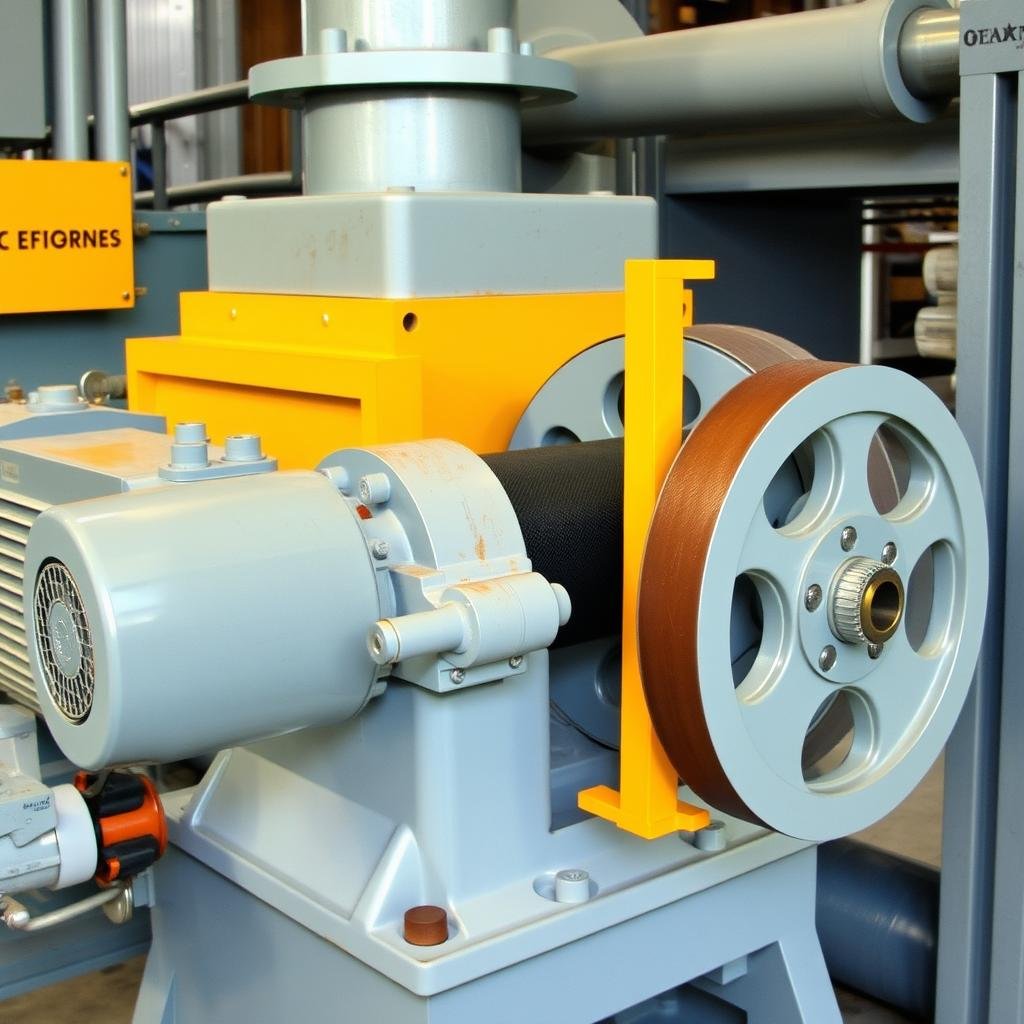

High-Efficiency Drive System

Premium efficiency motors coupled with optimized belt drive systems deliver maximum power transfer while minimizing energy consumption. The soft-start capability reduces mechanical stress during startup, extending component life and improving safety.

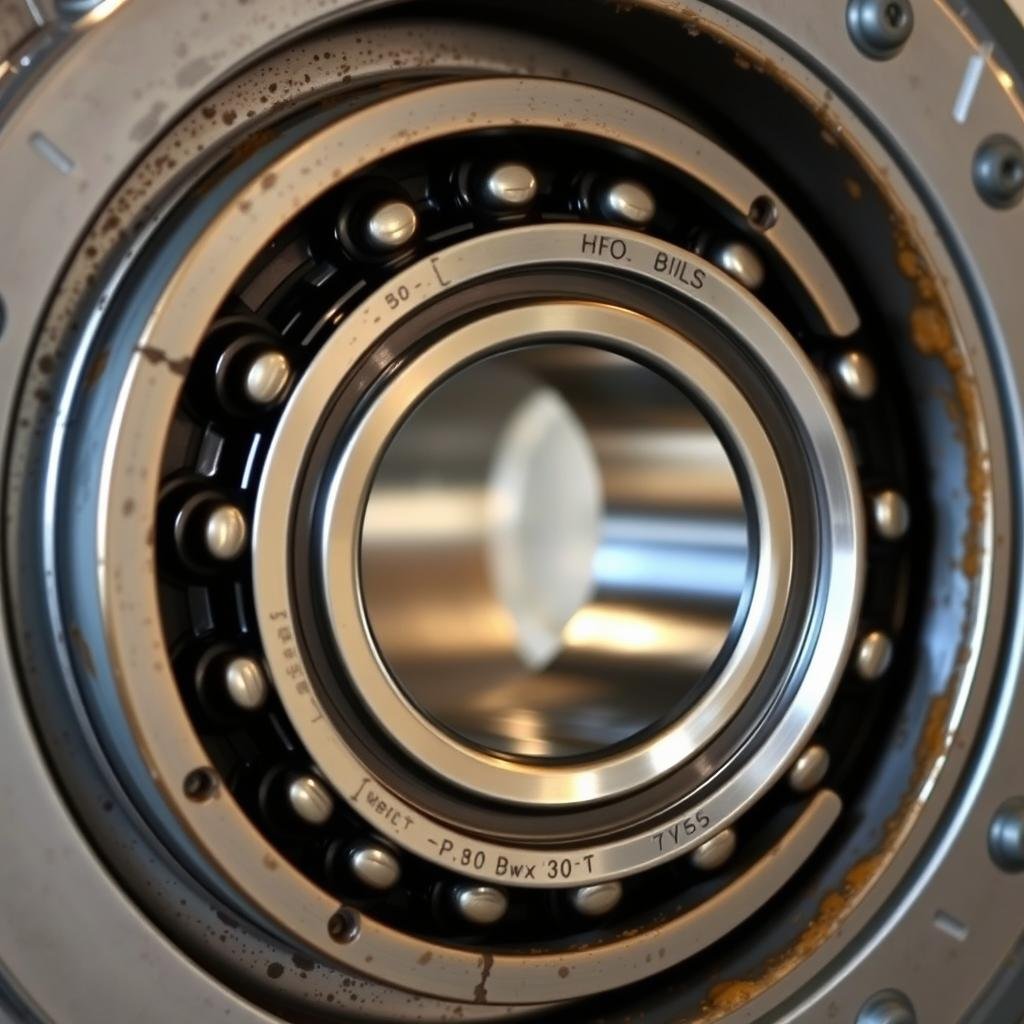

Robust Bearing Assembly

Oversized, self-aligning bearings with enhanced sealing provide exceptional reliability even in dusty environments. The automatic lubrication system ensures optimal bearing performance while minimizing maintenance requirements.

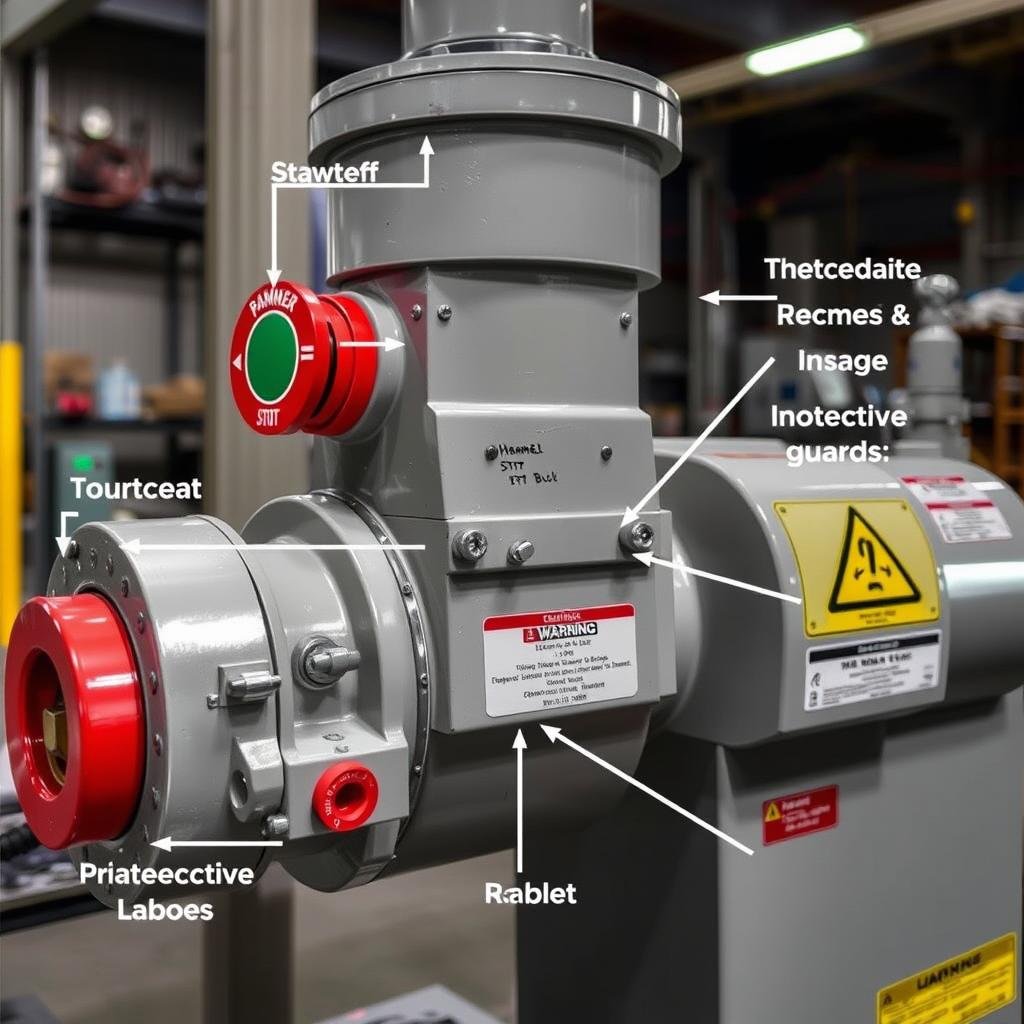

Integrated Safety Systems

Comprehensive safety features include emergency stop systems, vibration monitoring, amperage protection, and heavy-duty guards. These integrated safety systems protect both operators and equipment during operation.

Technical Questions About Our Hammer Mills?

Our engineering team is available to discuss specific technical details and customization options.

Customization Options for Your Specific Requirements

At MAIKONG, we understand that different grinding applications have unique requirements. That’s why we offer extensive customization options for our hammer mills for sale, ensuring you get a solution perfectly tailored to your specific needs.

Material-Specific Customizations

- Specialized hammer designs for specific materials (fibrous, brittle, or abrasive)

- Custom screen configurations for optimal particle size distribution

- Material-specific rotor designs for improved efficiency

- Enhanced wear protection for highly abrasive materials

- Specialized feeding systems for difficult-to-handle materials

Process Integration Customizations

- Custom inlet and outlet configurations for seamless integration

- Specialized control systems for automated operation

- Integration with existing material handling systems

- Custom mounting arrangements for space-constrained installations

- Special electrical configurations for compatibility with existing infrastructure

Need a Custom Hammer Mill Solution?

Our engineering team can develop a customized hammer mill configuration specifically for your application.

Hammer Mill Price Factors and Investment Considerations

The cost of a hammer mill depends on several factors, including capacity, construction materials, power requirements, and customization options. At MAIKONG, we strive to provide transparent pricing information to help you make an informed investment decision.

Key Factors Affecting Hammer Mill Price

Production Capacity

Higher capacity models with larger motors and more robust construction naturally command higher prices. Our range includes options from small 1-2 t/h units to industrial 25+ t/h systems to match your production requirements and budget.

Construction Materials

Premium materials like wear-resistant alloys for hammers and screens increase initial cost but provide superior durability and lower long-term operating costs. We offer various material options to balance initial investment against operational lifespan.

Customization Level

Specialized configurations for specific applications may increase costs but deliver superior performance for your particular needs. Our engineering team can help determine which customizations offer the best return on investment for your operation.

Typical Price Ranges for MAIKONG Hammer Mills

| Capacity Range | Typical Applications | Price Range (USD) | Key Features |

| 1-3 t/h | Small farms, research facilities | $7,000-$15,000 | Compact design, single-phase options, basic controls |

| 3-8 t/h | Medium farms, small feed mills | $15,000-$30,000 | Enhanced durability, improved efficiency, advanced controls |

| 8-15 t/h | Commercial feed mills, industrial processors | $30,000-$60,000 | Heavy-duty construction, automation options, high efficiency |

| 15-25+ t/h | Large industrial operations | $60,000-$100,000+ | Maximum durability, full automation, highest efficiency |

Value-Added Services: All MAIKONG hammer mills include technical documentation, installation guidance, and commissioning support. Extended warranty packages and preventive maintenance programs are available at additional cost to protect your investment.

Request a Personalized Quotation

Contact us today for a detailed price quote tailored to your specific requirements and production needs.

Why Choose MAIKONG Hammer Mills

MAIKONG Advantages

- Superior Build Quality: Premium materials and precision manufacturing ensure exceptional durability and reliability.

- Energy Efficiency: Optimized designs reduce power consumption by up to 15% compared to conventional hammer mills.

- Customization Capability: Extensive options to tailor solutions for specific applications and materials.

- Technical Support: Direct access to engineers via WhatsApp for immediate assistance with operational questions.

- Competitive Pricing: Factory-direct pricing eliminates middleman markups while maintaining premium quality.

- Spare Parts Availability: Comprehensive inventory of replacement parts ensures minimal downtime.

- Performance Guarantees: Written performance specifications backed by factory testing and validation.

What makes MAIKONG hammer mills different from competitors?

MAIKONG hammer mills stand out through their optimized hammer designs that deliver superior grinding efficiency, precision-balanced rotors that minimize vibration and extend bearing life, and our comprehensive customization capabilities that ensure the perfect match for your specific application. Additionally, our direct technical support via WhatsApp provides immediate assistance when you need it most.

How quickly can MAIKONG deliver a hammer mill to South Africa?

Standard models typically ship within 15-20 working days after order confirmation, with transit time to South Africa averaging 25-35 days depending on the destination port. Customized models may require 30-45 days for manufacturing before shipping. We work with reliable logistics partners to ensure efficient customs clearance and delivery to your facility.

What maintenance support is available for MAIKONG hammer mills?

We provide comprehensive maintenance documentation, video tutorials, and direct technical support via WhatsApp. Our engineers can guide your maintenance team through procedures remotely, and we can arrange on-site service through our network of technical partners in South Africa when needed. Preventive maintenance programs are also available to maximize equipment uptime.

Ready to Enhance Your Grinding Operations?

Contact MAIKONG today to discuss how our hammer mills can improve your productivity and product quality.

Get in Touch with MAIKONG

Contact Information

Our dedicated team is ready to assist you with product information, technical specifications, and customized solutions for your grinding needs.

- Email: Lucy@pelletmachine.co.za

- WhatsApp: +86 135 1090 7401

- Phone: +86 135 1090 7401

- Website: https://pelletmachine.co.za

Technical Support

Our engineering team provides comprehensive technical support to ensure optimal performance of your hammer mill.

Online Technical Support: We offer real-time technical assistance via WhatsApp, allowing our engineers to troubleshoot issues quickly and efficiently. Add our technical support number to your contacts for immediate assistance when needed.

Need Technical Assistance?

Our engineers are available to help with technical questions and operational support.

Invest in a Premium Hammer Mill for Optimal Grinding Performance

Choosing the right hammer mill for sale is a critical decision that impacts your operation’s efficiency, product quality, and bottom line. MAIKONG offers premium hammer mills that combine innovative design, superior materials, and precision engineering to deliver exceptional performance across various grinding applications.

With our extensive customization capabilities, competitive pricing, and dedicated technical support, MAIKONG is your ideal partner for industrial grinding solutions in South Africa. Contact us today to discuss your specific requirements and discover how our hammer mills can enhance your grinding operations.

Ready to Upgrade Your Grinding Capabilities?

Take the first step toward improved efficiency and product quality with a MAIKONG hammer mill.