South Africa Top pellet machine, animal feed pellet machine Manufacturer

MAIKONG: Your Trusted Partner in Pelletizing Technology

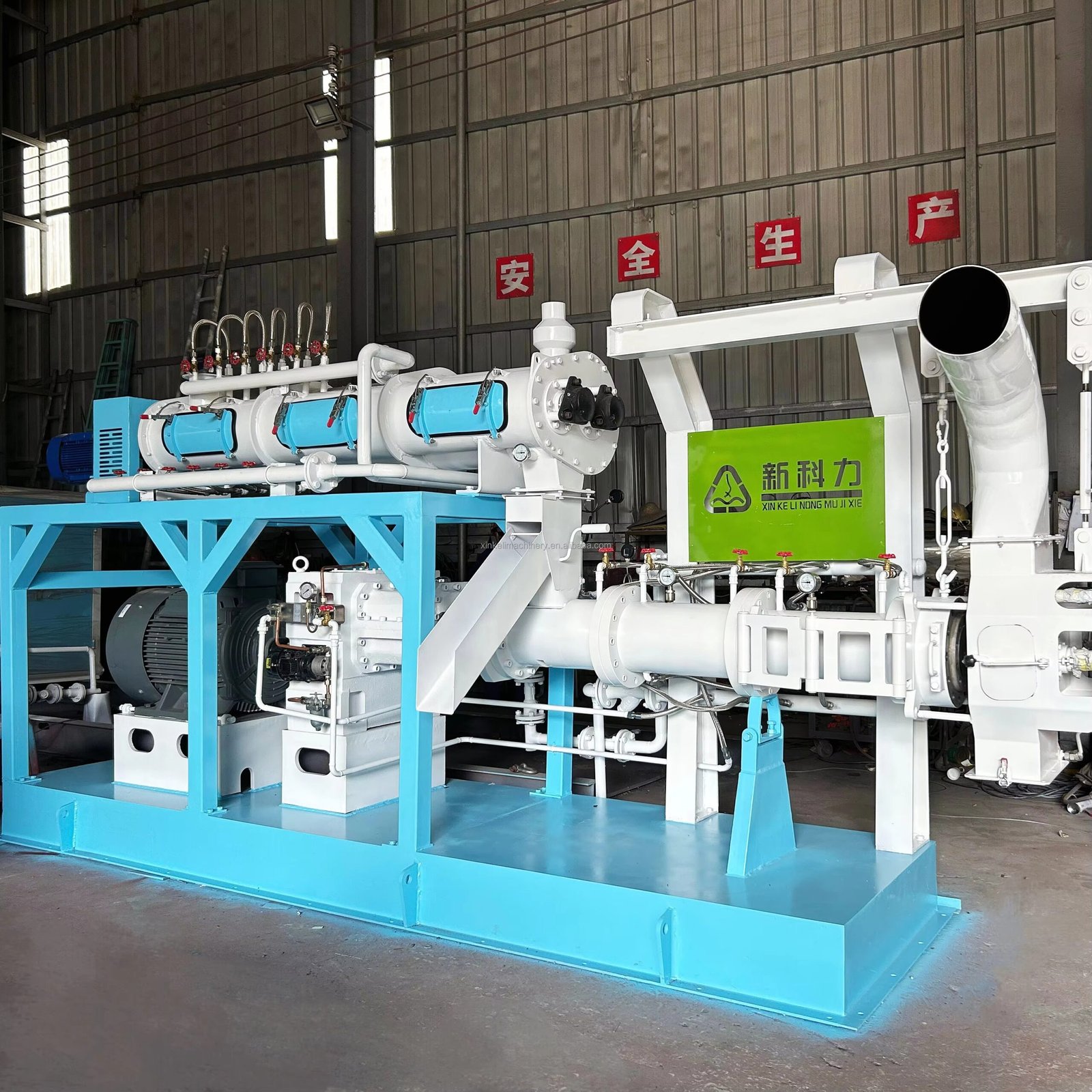

With nearly three decades of specialized experience, MAIKONG has established itself as a premier manufacturer of industrial pelletizer systems. Our state-of-the-art production facility in SZ, GD province combines precision engineering with rigorous quality control to deliver machines that consistently exceed industry standards.

Our Manufacturing Excellence

- Advanced production facilities spanning 20,000+ square meters

- ISO 9001:2015 certified manufacturing processes

- Cutting-edge CNC machining and automation

- Rigorous multi-stage quality testing protocols

- Experienced engineering team with 25+ years in pelletizing technology

Our Commitment to South Africa

- Dedicated technical support team for South African clients

- Comprehensive spare parts inventory for minimal downtime

- Custom solutions designed for local industry requirements

- Competitive pricing through direct manufacturer relationship

- Fast shipping with efficient customs clearance assistance

Ready to Enhance Your Production Capabilities?

Our technical consultants are available to discuss your specific pelletizing requirements and recommend the ideal solution for your operation.

Understanding Pelletizer Machine Functions and Applications

A pelletizer is specialized equipment designed to transform raw materials into uniform pellets through processes of extrusion, cutting, and cooling. These versatile machines serve as critical components in numerous industrial applications across South Africa’s manufacturing sector.

Core Pelletizer Machine Functions

Material Feeding

Advanced feeding systems ensure consistent material flow into the processing chamber, with variable speed control to optimize throughput based on material characteristics.

Extrusion Processing

High-precision extrusion systems apply controlled pressure and heat to transform raw materials into a homogeneous mass with precise density and composition.

Pellet Formation

Specialized die plates and cutting mechanisms create uniform pellets with customizable dimensions, ensuring consistency in size, shape, and density.

The pelletizer machine functions extend beyond basic processing to include advanced features such as temperature control, pressure monitoring, and automated operation sequences. These capabilities ensure optimal performance across diverse material types and production requirements.

Industry Applications

| Industry | Application | Benefits | Recommended Models |

| Plastic Recycling | Converting plastic waste into reusable pellets | Waste reduction, material recovery, revenue generation | MK-PL150, MK-PL250 |

| Animal Feed | Processing grain and supplements into feed pellets | Improved digestibility, reduced waste, easier storage | MK-FP100, MK-FP200 |

| Biomass Energy | Converting agricultural waste into fuel pellets | Sustainable energy production, waste utilization | MK-BP300, MK-BP500 |

| Pharmaceutical | Creating uniform pellets for medicinal applications | Precise dosing, improved bioavailability | MK-PP100, MK-PP150 |

| Chemical Processing | Producing chemical compound pellets | Controlled release, easier handling, dust reduction | MK-CP200, MK-CP300 |

Find the Perfect Pelletizer for Your Industry

Our technical team can help you select the ideal pelletizer configuration based on your specific material processing requirements.

MAIKONG Pelletizer Range: Technical Specifications

Our comprehensive range of pelletizer machines is designed to meet diverse production requirements across multiple industries. Each model incorporates advanced engineering features that ensure optimal performance, energy efficiency, and operational reliability.

Plastic Pelletizer Series

Our plastic pelletizer machine for sale range features cutting-edge technology for processing various polymer types, from virgin materials to recycled plastics. These systems deliver exceptional pellet quality with minimal energy consumption.

| Model | Capacity (kg/h) | Motor Power (kW) | Dimensions (mm) | Weight (kg) | Special Features |

| MK-PL150 | 80-150 | 11 | 1250×550×1100 | 260 | Dual roller system, Variable speed control |

| MK-PL250 | 200-300 | 22 | 1450×650×1250 | 380 | Automatic temperature control, Hardened cutting blades |

| MK-PL350 | 300-500 | 37 | 1650×750×1350 | 520 | Touchscreen control panel, Remote monitoring capability |

Feed and Biomass Pelletizer Series

Our feed and biomass pelletizer series is engineered for processing organic materials into high-density pellets for animal feed, biofuel, and other applications. These machines feature robust construction and specialized components for handling fibrous materials.

| Model | Capacity (kg/h) | Motor Power (kW) | Dimensions (mm) | Weight (kg) | Special Features |

| MK-FP100 | 80-100 | 3 | 1160×400×550 | 80 | Compact design, Single-phase power option |

| MK-BP300 | 200-300 | 15 | 1350×600×1200 | 320 | Reinforced die plate, High-pressure extrusion |

| MK-BP500 | 400-600 | 45 | 1850×850×1450 | 780 | Dual-stage compression, Automatic lubrication |

Specialized Pelletizer Options

Pith Pelletizer Machines

Our pith pelletizer machine for sale models are specifically designed for processing sugarcane bagasse, corn stalk pith, and similar materials. These specialized machines feature custom die configurations and moisture management systems.

Plastid Pelletizer Systems

Our plastid pelletizer machine for sale range incorporates advanced polymer processing technology for specialized applications in the medical, automotive, and consumer goods industries. These systems deliver exceptional precision and consistency.

Reconditioned Equipment

MAIKONG offers professionally reconditioned 2nd hand plastic pelletizer machine for sale options that provide excellent value without compromising on performance. Each refurbished unit undergoes comprehensive inspection, component replacement, and testing to ensure reliable operation.

Benefits of Reconditioned Pelletizers

- 30-50% cost savings compared to new equipment

- Fully tested and certified by MAIKONG technicians

- 6-month warranty included on all reconditioned units

- Immediate availability for faster deployment

- Environmentally responsible choice through equipment reuse

Considerations

- Limited model selection based on available inventory

- May have cosmetic imperfections despite mechanical excellence

- Potentially shorter operational lifespan than new equipment

- Some older models may lack the latest technological features

Find Your Ideal Pelletizer Solution

Whether you need a new high-capacity system or a cost-effective reconditioned unit, our team can help you find the perfect match for your production requirements.

Why Choose MAIKONG Pelletizers for Your South African Business

Superior Engineering

Our pelletizers feature precision-engineered components manufactured to exacting standards, ensuring consistent performance and exceptional durability even under demanding production conditions.

- Hardened steel cutting systems with extended service life

- Energy-efficient motor designs that reduce operational costs

- Precision-balanced rotors for minimal vibration and noise

Local Support

MAIKONG provides comprehensive technical support throughout South Africa, ensuring minimal downtime and optimal performance for your pelletizing operations.

- Responsive WhatsApp technical assistance

- Comprehensive documentation in English

- Spare parts inventory with fast delivery options

Cost Advantages

Our direct manufacturer relationship eliminates intermediaries, providing significant cost benefits without compromising on quality or performance.

- Competitive pricing on new equipment

- Value-oriented reconditioned options

- Lower total cost of ownership through durability

Regional Availability

MAIKONG has established a strong presence across South Africa, with particularly robust support in the North West province. Our pelletizer machine in North West installations have demonstrated exceptional reliability in mining-related applications, agricultural processing, and plastic recycling operations throughout the region.

Experience the MAIKONG Difference

Join hundreds of satisfied South African businesses that have enhanced their production capabilities with MAIKONG pelletizing technology.

Safety Considerations for Pelletizer Operations

Industrial pelletizing equipment requires proper safety protocols to ensure operator protection and equipment longevity. MAIKONG integrates comprehensive safety features into all our machines while providing detailed guidance on safe operation practices.

Pelletizer Machine Safety Hazards

Understanding potential pelletizer machine safety hazard factors is essential for creating a secure operating environment. Common hazards include:

- Mechanical Risks: Rotating components, cutting mechanisms, and pinch points present physical injury hazards during operation and maintenance.

- Thermal Hazards: Heating elements and friction-generated heat can cause burns if proper protocols are not followed.

- Electrical Hazards: Control systems and power components present electrical safety concerns, particularly during maintenance.

- Material Hazards: Certain processing materials may release fumes or dust that require proper ventilation and personal protective equipment.

- Noise Exposure: Extended operation may generate noise levels requiring hearing protection for operators.

Pelletizer Machine Safety Measures

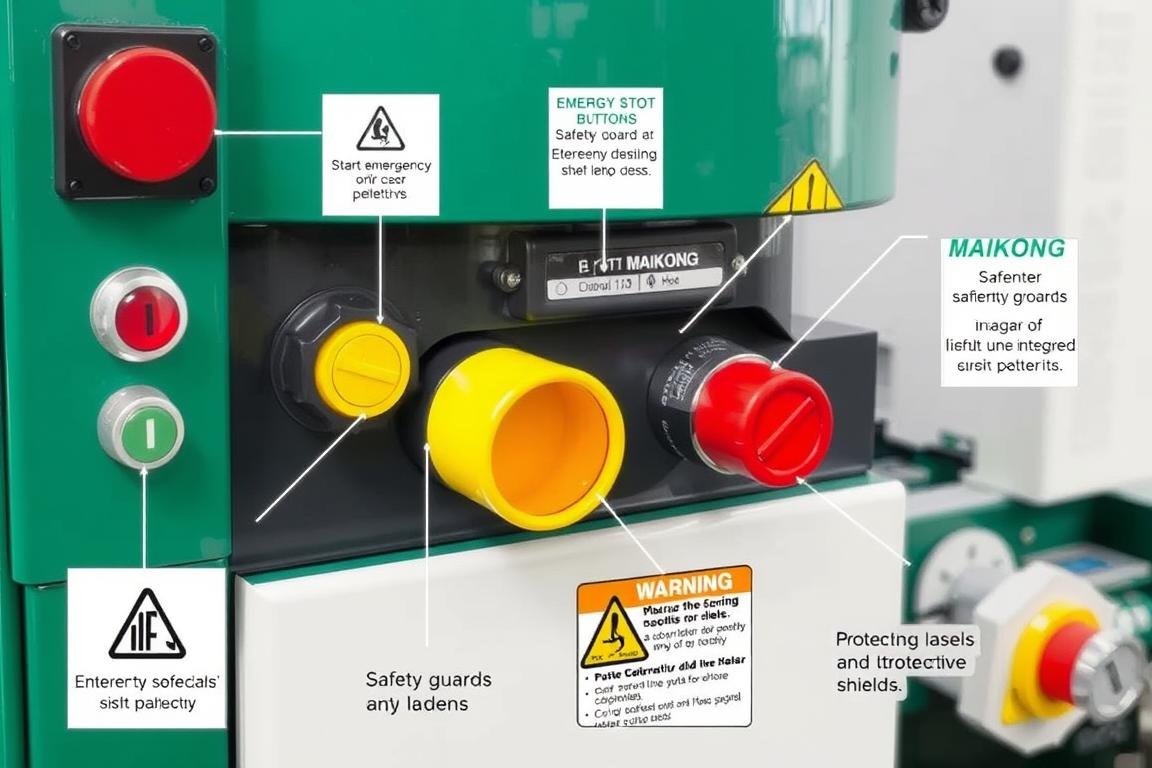

MAIKONG implements comprehensive pelletizer machine safety measures in all our equipment designs, including:

- Emergency Stop Systems: Strategically positioned emergency stop buttons that immediately halt all machine operations.

- Safety Interlocks: Access panels and maintenance doors equipped with interlocks that prevent operation when open.

- Machine Guarding: Physical barriers that prevent access to moving components during operation.

- Thermal Insulation: Heat-generating components are properly insulated to prevent accidental contact.

- Comprehensive Labeling: Clear warning labels and operational instructions in multiple languages including English.

- Overload Protection: Automatic systems that prevent damage from material jams or excessive load.

- Operator Training Materials: Detailed documentation and video resources for proper operational procedures.

Safety Certification

All MAIKONG pelletizer machines comply with international safety standards including CE certification and ISO 13849 safety requirements for machinery. Our equipment undergoes rigorous testing to ensure operator safety and mechanical reliability under all operating conditions.

Prioritize Safety in Your Pelletizing Operations

Request our comprehensive safety manual and operator training resources to ensure your team follows best practices for pelletizer operation.

Frequently Asked Questions About Pelletizers

What factors should I consider when selecting a pelletizer for my operation?

Key considerations include your production volume requirements, material characteristics (hardness, moisture content, etc.), desired pellet specifications (size, density), available power supply, space constraints, and budget. Our technical team can help assess these factors to recommend the most suitable model for your specific needs.

What maintenance is required for MAIKONG pelletizer machines?

Regular maintenance includes inspection of cutting blades, die plates, and bearings; lubrication of moving components; cleaning of material pathways; and inspection of electrical systems. MAIKONG provides detailed maintenance schedules and procedures in our operation manuals. Typical maintenance intervals range from daily inspections to monthly component checks, with major service recommended every 2,000 operating hours.

What is the difference between a strand pelletizer and an underwater pelletizer?

Strand pelletizers cool extruded material in water baths before cutting into pellets, making them suitable for most thermoplastics and offering excellent pellet uniformity. Underwater pelletizers cut molten material directly in a water chamber, providing advantages for heat-sensitive materials and higher production rates. MAIKONG offers both types to accommodate different material requirements and production objectives.

Are spare parts readily available for MAIKONG pelletizers in South Africa?

Yes, MAIKONG maintains a comprehensive inventory of spare parts for all our pelletizer models, with distribution centers serving South Africa. Common wear components such as cutting blades, die plates, and bearings are available for immediate shipment. For specialized components, our efficient supply chain ensures delivery within 7-10 business days. We also provide detailed parts catalogs and maintenance kits for preventive maintenance programs.

What warranty coverage is provided with MAIKONG pelletizers?

New MAIKONG pelletizers include a comprehensive 24-month warranty covering manufacturing defects and component failures under normal operating conditions. Reconditioned machines come with a 6-month warranty. Extended warranty options are available for up to 5 years. Our warranty includes technical support and replacement parts, with service available throughout South Africa.

Contact MAIKONG for Your Pelletizer Requirements

Get Expert Assistance

Our technical consultants are available to discuss your specific pelletizing requirements, recommend appropriate equipment, and provide detailed quotations tailored to your operation.

- WhatsApp Support: +86 13510907401 for immediate technical assistance

- Email: Lucy@pelletmachine.co.za for inquiries and quotations

- Website: https://pelletmachine.co.za for product information

Request a Quotation

Ready to Enhance Your Production Capabilities?

Contact us today to discuss your pelletizing requirements and discover how MAIKONG’s advanced technology can optimize your operations.