South Africa Top pellet machine, animal feed pellet machine Manufacturer

Why Specialized Rabbit Pellet Production Matters

Rabbit farming success depends heavily on nutrition management. While traditional feeding methods might seem economical initially, they create significant long-term challenges:

Challenges of Traditional Feeding

- Inconsistent nutrition leading to growth variations

- Higher feed waste from scattered loose materials

- Increased risk of contamination and disease

- Limited storage capability and shorter shelf life

- Difficulty in precise nutrition management

Benefits of Pelletized Rabbit Feed

- Uniform nutrition in every pellet prevents selective eating

- 99% feed utilization rate (vs. 92% with loose feed)

- Extended storage life through moisture reduction

- Reduced bacterial contamination through processing

- Complete control over feed formulation

Ready to Optimize Your Rabbit Feed Production?

Our technical team can help you select the right machine for your operation size.

MAIKONG: Leading Rabbit Pellet Machine Manufacturer

Based in SZ, GD, China, MAIKONG has established itself as a premier manufacturer of animal feed processing equipment. With over 30 years of industry experience, we’ve built a reputation for engineering excellence and customer-focused solutions.

Superior Supply Chain

Our integrated Chinese supply chain ensures consistent quality and competitive pricing. We source premium components including Siemens motors and high-grade stainless steel to manufacture machines that outperform and outlast competitors.

Advanced Manufacturing

Our state-of-the-art production facilities employ precision engineering techniques including high-precision aviation-grade gear grinding technology. Every machine undergoes rigorous quality testing before shipment.

Customization Capability

We understand that each rabbit farming operation has unique requirements. Our engineering team can customize any aspect of our machines to match your specific production needs, feed formulations, and facility constraints.

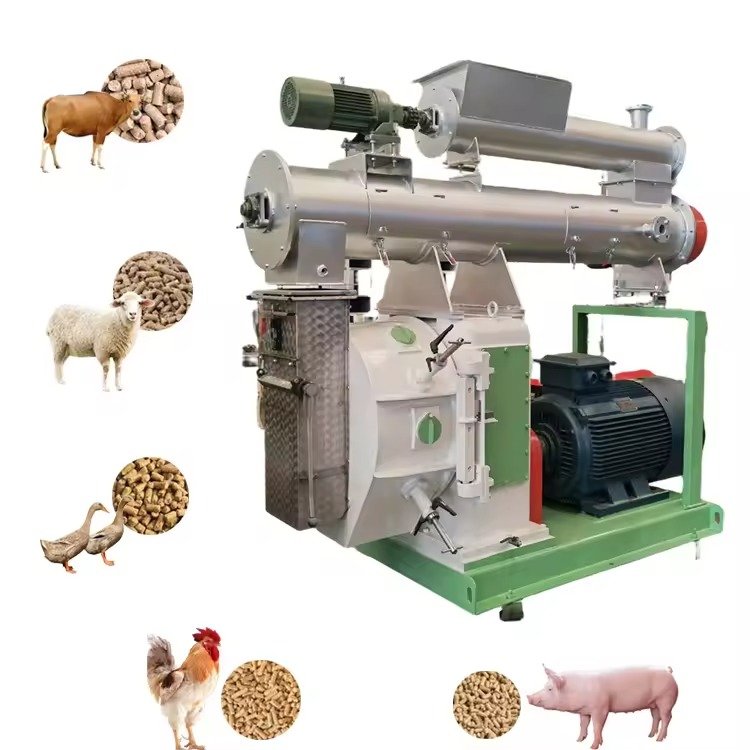

MK-Series Rabbit Pellet Making Machine Specifications

Our comprehensive range of rabbit pellet making machines accommodates operations of all sizes, from small farms producing 150 kg per day to large commercial facilities requiring tons of daily output.

| Model | Output (kg/h) | Motor Power (kW) | Pellet Diameter (mm) | Dimensions (m) | Weight (kg) |

| MK-SZLH125 | 50-80 | 3 | 2-12 | 0.66×0.32×0.68 | 90 |

| MK-SZLH150 | 100-150 | 4 | 2-12 | 0.78×0.32×0.75 | 120 |

| MK-SZLH210 | 200-400 | 7.5 | 2-12 | 0.97×0.43×0.95 | 210 |

| MK-SZLH230 | 300-500 | 11 | 2-12 | 1.15×0.48×1.05 | 280 |

| MK-SZLH260 | 500-600 | 15 | 2-12 | 1.25×0.52×1.1 | 350 |

Key Technical Features

Premium Ring Die System

Our machines feature high-quality stainless steel ring dies with customizable apertures between 1.5mm and 12mm. This allows for precise control over pellet size based on rabbit age and nutritional requirements.

Reliable Siemens Motors

All MAIKONG rabbit pellet machines are equipped with premium Siemens motors, ensuring consistent performance, energy efficiency, and exceptional durability even under continuous operation.

Precision Gear Transmission

Our main transmission system uses high-precision aviation-grade gear grinding technology, ensuring smooth operation with 15% higher output than belt-driven alternatives while maintaining lower noise levels.

Comprehensive Safety Features

Every machine includes safety pins for overload protection, automatic power-off when the door cover is opened, and fully enclosed transmission parts to ensure operator safety and equipment longevity.

Need Custom Specifications?

Our engineering team can customize any machine to meet your specific requirements.

Advantages of MAIKONG Rabbit Pellet Making Machines

Operational Benefits

- Energy-efficient design reduces power consumption by up to 15%

- Variable frequency control allows precise feed rate adjustment

- Stainless steel components prevent contamination and extend service life

- Compact design requires minimal floor space in your facility

- Low noise operation (under 85dB) improves working environment

- Simple maintenance procedures reduce downtime

Economic Advantages

- Reduce feed costs by up to 30% through in-house production

- Increase feed utilization rate to 99% (vs. 92% with loose feed)

- Extend feed storage life from 1 month to 3-6 months

- Utilize lower-cost alternative ingredients in custom formulations

- Improve rabbit growth rates and reduce time to market

- Quick ROI – typically 6-18 months depending on operation size

South African Market Advantages

MAIKONG machines are specifically optimized for the South African market, with features that address local farming challenges:

Dual Power Options

Our machines can be configured for both electric and diesel operation, providing flexibility during load shedding and in remote areas with unreliable electricity.

Local Material Compatibility

Specially designed to process South African raw materials including lucerne (alfalfa), maize, wheat bran, and local grasses with optimal efficiency.

Readily Available Spare Parts

We maintain comprehensive spare parts inventory with fast shipping to minimize any potential downtime in your operation.

Applications and Use Cases

Versatile Feed Production

MAIKONG rabbit pellet making machines excel in producing specialized feed for various rabbit farming applications:

Meat Rabbit Production

Create high-protein, growth-optimized pellets for meat rabbit varieties like New Zealand White and Californian breeds. Customize fat and protein content to maximize growth rates and meat quality.

Angora Wool Production

Formulate specialized pellets with enhanced protein and mineral profiles to support optimal wool growth and quality for Angora rabbits, improving fiber yield and texture.

Breeding Stock Nutrition

Produce reproductive-focused feed formulations with precise nutrient balances to support doe fertility, kit development, and buck performance in breeding operations.

Raw Material Flexibility

Our machines efficiently process a wide range of ingredients commonly used in South African rabbit farming:

Primary Ingredients

- Lucerne/Alfalfa (primary fiber source)

- Maize/Corn (energy source)

- Wheat bran (fiber and moderate protein)

- Grass and forage materials

- Soybean meal (protein supplement)

Supplements & Additives

- Mineral premixes for bone development

- Vitamin supplements for overall health

- Probiotics for digestive health

- Molasses (binding agent and palatability)

- Medicinal additives when required

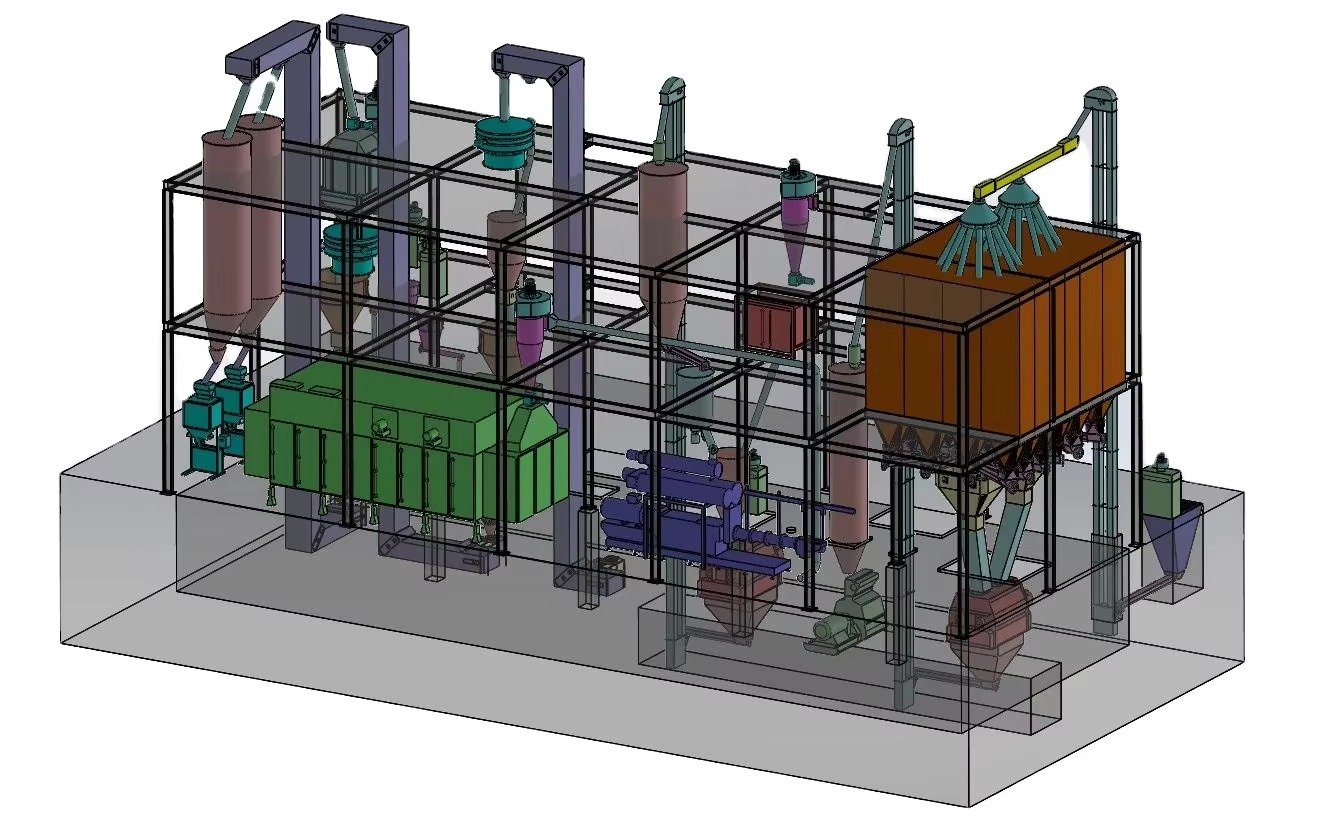

Integration Capabilities

MAIKONG rabbit pellet making machines can operate as standalone units or integrate into complete feed production lines:

Standalone Operation

Perfect for farms that prepare their own ingredient mix and need only the pelleting function. Our compact machines require minimal space and setup.

Small Complete Lines

Combine with our hammer mills, mixers, and cooling systems for a complete small-scale production line producing 150kg-500kg per day.

Industrial Integration

Seamlessly integrate into existing large-scale feed production facilities with our industrial models capable of tons per day output.

Pricing and Value Proposition

MAIKONG offers competitive pricing on all rabbit pellet making machines, with transparent cost structures that deliver exceptional value for South African farmers and feed producers.

| Production Scale | Recommended Model | Daily Output | Price Range (USD) | Typical ROI Period |

| Small Farm | MK-SZLH125/150 | 150-1200 kg | $7,000-12,000 | 12-18 months |

| Medium Farm | MK-SZLH210/230 | 1600-4000 kg | $15,000-25,000 | 10-14 months |

| Large Operation | MK-SZLH260/300 | 4000-5600 kg | $28,000-45,000 | 8-12 months |

| Commercial | MK-SZLH360/400 | 5600-9600 kg | $50,000-100,000 | 6-10 months |

Customization Impact on Pricing

We offer various customization options to meet your specific requirements:

Standard Inclusions

- Base machine with standard ring die

- Siemens motor and control panel

- Standard safety features

- Basic tools and operation manual

- Standard warranty package

Premium Customizations

- Additional ring dies (+$500-1500 per die)

- Dual power systems (electric/diesel) (+15-20%)

- Enhanced cooling systems (+$1000-3000)

- Automated control upgrades (+$2000-5000)

- Extended warranty packages (+5-10%)

Payment and Shipping Terms

What are the standard payment terms?

We offer flexible payment options:

- 40% deposit by T/T after contract signing, 60% balance before shipment

- 40% deposit by T/T after contract signing, 60% balance by L/C

- Custom payment terms available for established businesses

What is the typical delivery timeframe to South Africa?

Standard machines: 10-30 working days production + 20-30 days shipping

Customized machines: 30-45 working days production + 20-30 days shipping

Complete production lines: 30-90 days production + 30-45 days shipping

Request Detailed Quotation

Get a customized quote based on your specific production requirements.

Why Choose MAIKONG Rabbit Pellet Making Machines

Quality Assurance

All MAIKONG machines are manufactured under strict quality control systems and carry ISO9001-2000, CE, and SGS certifications. Each machine undergoes comprehensive testing before shipment to ensure perfect operation upon arrival.

Industry Experience

With over 30 years of specialized experience in feed processing equipment, MAIKONG brings unmatched expertise to rabbit pellet production. Our engineering team continuously refines our designs based on customer feedback and industry developments.

Global Reputation

MAIKONG equipment operates successfully in over 140 countries worldwide, including significant installations throughout Africa. Our machines have proven their reliability and performance in diverse operating environments.

Comprehensive Support for South African Customers

Our Commitment to Your Success

When you choose MAIKONG, you’re not just buying a machine – you’re gaining a long-term partner committed to your rabbit farming success:

Pre-Sale Consultation

Our technical team works with you to understand your specific requirements, production goals, and facility constraints before recommending the optimal solution for your operation.

Installation Support

We provide comprehensive installation guides, video tutorials, and real-time technical assistance to ensure your equipment is properly set up and optimized for your specific conditions.

Ongoing Technical Support

Our South Africa-focused support team is available via WhatsApp for immediate technical assistance, troubleshooting, and optimization advice throughout the life of your equipment.

Contact MAIKONG for Technical Support and Quotations

Technical Support

Our technical team is ready to answer your questions and provide expert guidance.

Request a Quotation

Get a detailed quote tailored to your specific production requirements.

Visit Our Website

Explore our complete range of feed processing equipment and production lines.

Ready to Transform Your Rabbit Feed Production?

Contact us today to discuss how MAIKONG’s rabbit pellet making machines can optimize your operation, reduce costs, and improve feed quality. Our team is ready to provide expert guidance tailored to South African farming conditions.