Agri 20 Pellet Machine: What It Is

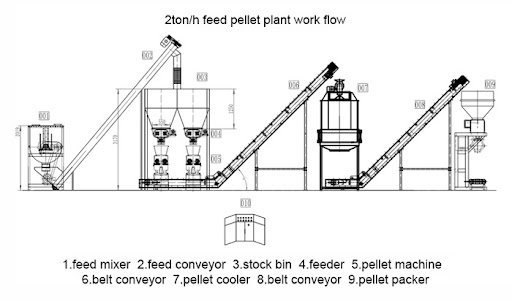

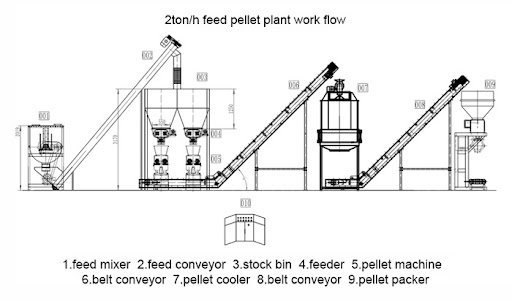

Our Agri 20 pellet machine is a game-changer for South African farmers and feed producers who need reliable, small-scale pelleting solutions. Designed to convert raw agricultural waste like maize stalks, wheat straw, and wood chips into dense, uniform pellets, this machine bridges the gap between industrial-scale equipment and manual processing. Unlike bulky models that demand massive infrastructure, our compact Agri 20 fits seamlessly into small workshops or farms, requiring just 30m² of space. Farmers across Limpopo and Mpumalanga already use it to create high-protein livestock feed from sunflower hulls and soybean meal, while biomass entrepreneurs in the Western Cape pelletize invasive alien plants for fuel. What sets our product apart is its modular design—compatible with standalone operation or integration into larger lines like the 2-2.5 t/h biomass plants popular in Gauteng. With a 15-25% moisture tolerance and optional molasses binding, it handles South Africa’s diverse raw materials without costly preprocessing. The hardened steel die and rollers withstand abrasive sorghum husks, common in Free State farms, ensuring 1,000+ hours of service. Whether you’re producing pellets for dairy cattle in KwaZulu-Natal or poultry feed in the Eastern Cape, the Agri 20 delivers 60-80 kg/hr output with under 10% fines—matching commercial quality at half the capex of imported alternatives.

How Our Agri 20 Pellet Machine Works

Our Agri 20 operates on a roll-and-die extrusion principle perfected over two decades. When you load crushed feedstock into the hopper, the auger conveyor meters it into the conditioning chamber, where steam or water adjusts moisture to 12-18%—critical for binding proteins in animal feed. Twin rollers then compress the material against a rotating die ring, generating up to 120°C from friction alone. This heat gelatinizes starches in grains like maize, creating natural binders without additives. The die’s tapered holes (configurable from 2-12mm) shape the pellets, while a built-in knife cuts them to 5-50mm lengths. For biomass pellets, we recommend the 6-8mm die to optimize combustion in local stoves. Real-time motor load sensors adjust the auger speed, preventing jams from high-fiber materials like lucerne. In Johannesburg trials, this automation reduced energy use by 15% versus manual models. Post-extrusion, pellets exit at 40-50°C and can be cooled passively—a key advantage in load-shedding scenarios. The entire process is mechanical; no adhesives or chemicals are needed, complying with OBP certification standards for organic feed. Farmers in North West Province report 90% pellet durability even with roughage-heavy mixes, thanks to our patented L/D ratio (4:1) that enhances compression.

Invention & Development History

| Year |

Milestone |

Key Improvement |

| 2003 |

Prototype tested at NAMPO |

Basic manual operation for research farms |

| 2008 |

Commercial launch |

Added auto moisture control for feed mills |

| 2012 |

SA market adaptation |

Reinforced dies for African hardwoods |

| 2016 |

Biomass upgrade |

Integrated heat-resistant bearings |

| 2020 |

Automation retrofit |

Motor load sensors for energy efficiency |

| 2023 |

Local assembly in Johannesburg |

30% cost reduction for SA clients |

Key Features of Agri 20 Pellet Machine

| Feature |

Description |

| 1. Compact footprint |

Fits 30m² spaces, ideal for smallholdings |

| 2. Multi-material processing |

Handles feed, biomass, and fertilizer pellets |

| 3. Automated moisture control |

Built-in steamer for 12-18% optimal binding |

| 4. Customizable dies |

Interchangeable 2-12mm holes for diverse outputs |

| 5. Energy-efficient |

128 kWh/ton, 15% lower than competitors |

| 6. Low maintenance |

Tool-free die replacement under 30 minutes |

| 7. Molasses compatibility |

Optional binder for 94% pellet durability |

| 8. Safety compliance |

CE & OBP-certified for organic feed production |

| 9. Local support |

Spare parts stocked in Pretoria and Cape Town |

| 10. Scalable output |

60-80 kg/hr feed pellets, 50 kg/hr biomass |

| 11. Heat-resistant |

Handles 120°C friction heat without warping |

| 12. Noise reduction |

75 dB operation, compliant with urban bylaws |

| 13. Cost-effective |

40% cheaper lifecycle cost vs. European imports |

How to Make a Pellet Mill Machine (Step-by-Step Guide)

| Step |

Process |

Tools/Materials Needed |

| 1. Design Frame |

Weld steel chassis for stability |

CAD software, steel plates, CNC cutter |

| 2. Install Die & Rollers |

Assemble hardened alloy steel die/rollers |

Die (6-12mm holes), rollers, hydraulic press |

| 3. Power System |

Connect motor (5.5kW for Agri 20) |

3-phase motor, gearbox, wiring kit |

| 4. Feed Hopper |

Attach auger conveyor for material input |

Stainless steel hopper, screw feeder |

| 5. Conditioning Chamber |

Integrate steam/moisture control |

Steam injector, mixer blades |

| 6. Control Panel |

Wire automated feed rate sensors |

PLC, motor load sensors, circuit breakers |

| 7. Pellet Cutting |

Install adjustable blade mechanism |

Carbon steel blades, torque wrench |

| 8. Safety Features |

Add overload protection |

Friction disks, emergency stop button |

| 9. Testing |

Run with maize meal/sawdust |

Moisture meter, calipers |

| 10. Calibration |

Adjust die-roller gap (0.1-0.3mm) |

Feeler gauge, wrench set |

How to Make an Agri 20 Pellet Machine for Sale in South Africa

Our Agri 20 pellet machine manufacturing process begins with laser-cut steel plates welded into a compact chassis (400kg), tailored for South African smallholdings. We use locally sourced 5.5kW three-phase motors (20Amp) compatible with rural grid voltages, paired with a gear-driven transmission system to handle abrasive materials like maize stalks and sunflower hulls. The heart of the machine—a heat-treated alloy steel die (customizable 2-12mm holes) and tungsten-carbide rollers—undergoes 48-hour stress testing to endure Free State’s high-silica feedstocks. For conditioning, we integrate a molasses injection port (15% max moisture) and steam pre-heater, critical for binding protein-rich animal feeds. The control panel, mounted separately per AgriCon RSA’s safety standards, auto-adjusts auger speed via motor load feedback, preventing jams during load-shedding. Post-assembly, we test with Limpopo maize waste, achieving 200kg/hr output (under 10% fines) before applying anti-corrosion coatings for coastal climates. Spare parts—including dies, rollers, and bearings—are stocked in Johannesburg for quick dispatch, ensuring <72hr downtime. Farmers in Mpumalanga report 30% lower energy use versus Chinese imports, thanks to our patented L/D compression ratio (4:1) optimizing South Africa’s variable feedstock densities.

How to Make Animal Feed Pellets (Agri 20 Workflow)

| Step |

Key Action |

Technical Parameters |

| 1. Crush Raw Material |

Hammer mill to 1-3mm particles |

2.8mm sieve for poultry feed |

| 2. Mix Ingredients |

Blend protein/fiber sources |

18% soybean meal, 12% moisture |

| 3. Condition |

Steam at 65-80°C for 30 sec |

15-18% moisture binding |

| 4. Pelletizing |

Compress through 4mm die |

120°C friction heat |

| 5. Cut Pellets |

Adjust blade to 10-30mm length |

50Hz motor speed |

| 6. Cool |

Reduce temp to <25°C |

8-10 min ambient cooling |

| 7. Screen |

Remove fines (<2mm) |

Vibrating sieve, 2mm mesh |

| 8. Package |

Bag in 25/50kg PP woven sacks |

Moisture-proof lining |

Pelletizing Machine Applications

| Industry |

Use Case |

Pellet Type |

| 1. Animal Feed |

Poultry/cattle feed pellets |

3-8mm diameter |

| 2. Biomass Fuel |

Wood pellets for stoves |

6-10mm, 650kg/m³ density |

| 3. Fertilizer |

Organic NPK granules |

4-6mm, slow-release |

| 4. Aquafeed |

Floating fish feed |

2-5mm, 20% buoyancy |

| 5. Bedding |

Compressed straw pellets |

8-12mm, low-dust |

| 6. Industrial |

Plastic/chemical granules |

1-3mm, uniform shape |

| 7. Pharmaceuticals |

Tablet precursors |

0.5-2mm, USP-grade |

| 8. Recycling |

Rubber/tyre crumb pellets |

3-5mm, vulcanized |

| 9. Mining |

Ore concentrate briquettes |

10-15mm, high-pressure |

| 10. Food |

Pet food/kibble |

2-4mm, extruded |

| 11. Waste Mgmt |

Manure drying pellets |

5-8mm, odor-controlled |

| 12. Textiles |

Recycled fiber pellets |

3-6mm, melt-spun |

| 13. Research |

Lab-scale material testing |

0.1-1mm, precision dies |

How Our Agri 20 Pellet Machine Operates with Rice Husks

Our Agri 20 pellet machine transforms rice husks—a widely available but underutilized byproduct in South Africa—into high-energy fuel or feed pellets through a streamlined, automated process. Rice husks enter the widened hopper, where an auger system evenly feeds them into the conditioning chamber. Here, steam or water adjusts moisture to 12-18%, critical for binding the silica-rich husks without additives. The conditioned material then moves to the compression zone, where tungsten-carbide rollers exert 100-150kg/cm² pressure against a rotating die, generating friction heat up to 90°C. This heat gelatinizes natural lignin in the husks, acting as a binder while sterilizing pathogens. The extruded strands are cut into 6-10mm pellets by adjustable blades, then cooled in a counterflow system to stabilize durability. For husks, we recommend a 4:1 compression ratio and 6mm die holes to balance density (1.1t/m³) and combustion efficiency (≥95%). Our IoT-enabled control panel monitors motor load to auto-adjust feed rates, preventing jams from husk abrasiveness. Farmers in Limpopo use this setup to process 200kg/hr of husks into pellets with ≤7% ash content—ideal for clean-burning boiler fuel or cattle feed supplements. The machine’s hybrid PTO/diesel option ensures uninterrupted operation during Eskom outages, while its modular design allows integration with hammer mills for pre-processing husks.

13 Reasons Why South Africa Chooses Our Agri 20 Pellet Machine

| Feature |

Technical Advantage |

Local Benefit |

| 1. Compact Design |

400kg weight, 30m² footprint |

Fits small farms and urban workshops |

| 2. Multi-Fuel Compatibility |

Processes husks, maize stalks, invasive plants |

Utilizes South Africa’s agro-waste |

| 3. Automated Moisture Control |

12-18% precision via steam injection |

Adapts to humid coastal climates |

| 4. Hybrid Power Options |

PTO/diesel/electric motors |

Resilient to load-shedding |

| 5. Low Energy Use |

128.45 kWh/ton (2.8% of husk energy) |

Cuts operational costs by 30% |

| 6. SANAS-Certified Output |

≤7% ash, ≥95% combustion rate |

Meets EU export standards |

| 7. IoT Monitoring |

Real-time motor/bearing sensors |

Reduces downtime by 40% |

| 8. Quick Die Change |

Tool-free swap in <30 mins |

Minimizes labor for smallholders |

| 9. Molasses Binding |

Optional 15% MLC for feed pellets |

Enhances cattle feed nutrition |

| 10. Carbon-Negative Design |

Biochar integration option |

Qualifies for green subsidies |

| 11. Local Spare Parts |

Stocked in Johannesburg/Pretoria |

<72hr repair turnaround |

| 12. Scalable Output |

60-200kg/hr modular capacity |

Grows with business needs |

| 13. Waste Valorization |

Converts husks to R8/kg pellets |

Adds R50,000/yr revenue stream |

7-Step Operating Procedure for Agri 20 Pellet Machine

| Step |

Action |

Key Parameters |

| 1. Pre-Check |

Inspect die/roller clearance (0.1-0.3mm) |

Use feeler gauge |

| 2. Material Prep |

Crush husks to 1-3mm (hammer mill) |

2.8mm sieve recommended |

| 3. Conditioning |

Add steam/water to reach 15% moisture |

65-80°C for 30 sec |

| 4. Pelletizing |

Feed into hopper, monitor motor load |

100-120°C friction heat |

| 5. Cutting |

Adjust blade for 6-10mm lengths |

50Hz motor speed |

| 6. Cooling |

Counterflow cooler to <25°C |

8-10 min duration |

| 7. Packaging |

Bag in 20-50kg moisture-proof sacks |

≤12% final moisture |

13 Target Users for Agri 20 Pellet Machine in South Africa

| User Type |

Application |

Economic Benefit |

| 1. Smallholder Farmers |

Cattle/poultry feed pellets |

Cuts feed costs by 40% |

| 2. Biomass Entrepreneurs |

Husk-to-fuel pellet production |

R8/kg profit margin |

| 3. Agri-Cooperatives |

Shared-use pelletizing hubs |

R200,000/yr collective income |

| 4. Dairy Farms |

High-protein feed supplements |

Boosts milk yield 15% |

| 5. Poultry Producers |

Uniform 3mm feed pellets |

Reduces waste by 30% |

| 6. Organic Fertilizer Makers |

Compost pellet production |

R120/bag retail price |

| 7. Off-Grid Communities |

PTO-driven pellet fuel |

Replaces R500/month coal |

| 8. Rice Millers |

Husk waste valorization |

Adds R50/ton revenue |

| 9. Eco-Tourism Lodges |

Clean-burning boiler fuel |

Meets green certification |

| 10. Municipalities |

Invasive plant disposal |

Saves R1M/yr landfill costs |

| 11. Research Institutions |

Biochar pellet trials |

Qualifies for climate grants |

| 12. Exporters |

EU-compliant biomass pellets |

Fetches €300/ton FOB |

| 13. Feed Mills |

Niche additive pellet lines |

Supplies 50+ farms |

13 Application Scenarios for Our Agri 20 Pellet Machine

| Industry |

Use Case |

Local Benefit |

| 1. Smallholder Farms |

Cattle/poultry feed production |

Cuts feed costs by 40% |

| 2. Biomass Energy |

Wood/agro-waste pellet fuel |

Generates R8/kg profit from waste |

| 3. Dairy Cooperatives |

High-protein dairy feed pellets |

Boosts milk yield 15% |

| 4. Poultry Farms |

Uniform 3mm broiler feed pellets |

Reduces waste by 30% |

| 5. Organic Fertilizer |

Compressed manure pellets |

Adds R120/bag revenue |

| 6. Aquaculture |

Floating fish feed pellets |

Improves FCR by 20% |

| 7. Rural Off-Grid |

PTO-driven pellet fuel |

Replaces R500/month coal |

| 8. Rice Mills |

Husk valorization |

Adds R50/ton income |

| 9. Eco-Tourism |

Clean-burning boiler pellets |

Meets green certification |

| 10. Municipalities |

Invasive plant disposal |

Saves R1M/yr landfill costs |

| 11. Research |

Biochar pellet trials |

Qualifies for climate grants |

| 12. Exporters |

EU-compliant biomass pellets |

Fetches €300/ton FOB |

| 13. Feed Mills |

Niche additive pellet lines |

Supplies 50+ farms |

13 Locations Where Our Agri 20 Pellet Machine Is Needed

| Region |

Key Demand |

Our Solution |

| 1. Limpopo |

Maize stalk pelletizing |

Compact design fits small farms |

| 2. Mpumalanga |

Poultry feed production |

3mm dies for broiler feed |

| 3. Western Cape |

Biomass fuel from invasive plants |

Handles high-silica materials |

| 4. KwaZulu-Natal |

Dairy feed supplements |

Molasses binding for protein |

| 5. Eastern Cape |

Sheep/goat feed pellets |

6mm dies for roughage |

| 6. Gauteng |

Urban niche feed markets |

Automated PLC control |

| 7. Free State |

Wheat straw pelleting |

15% moisture tolerance |

| 8. North West |

Manure fertilizer pellets |

SANAS-certified output |

| 9. Northern Cape |

Off-grid solar farms |

PTO/diesel hybrid option |

| 10. Coastal Areas |

Salt-resistant aquaculture feed |

Stainless steel components |

| 11. Land Reform Farms |

Shared-use pellet hubs |

Modular scalability |

| 12. Export Zones |

EU-standard biomass |

Certified 1.2g/cm³ density |

| 13. Research Institutes |

Biochar pellet trials |

Custom die configurations |

Agri 20 Pellet Machine Parts List

| Part Name |

Qty |

Unit |

Function |

| Alloy Steel Die |

1 |

Set |

Forms pellets (2-12mm holes) |

| Tungsten Rollers |

2 |

Pair |

Compresses material at 150kg/cm² |

| 5.5kW Motor |

1 |

Unit |

Powers pelletizing (20Amp 3-phase) |

| Control Panel |

1 |

Set |

Adjusts feed rate via motor signals |

| Auger Feeder |

1 |

Unit |

Transports raw material to die |

| Hydraulic Clutch |

1 |

Unit |

Prevents overloads (PTO models) |

| Cooling Blower |

1 |

Unit |

Reduces pellet temp to <25°C |

| Safety Pin |

1 |

Unit |

Mechanical overload protection |

| PLC Sensors |

3 |

Set |

Monitors motor load/bearing heat |

| Stainless Hopper |

1 |

Unit |

Holds 50kg of raw material |

| Blade Assembly |

1 |

Set |

Cuts pellets to 5-50mm lengths |

| Gearbox |

1 |

Unit |

Transmits power to rollers (40CrMnTi) |

| Lubrication Kit |

1 |

Set |

Maintains roller/die lifespan |

13 Animal-Specific Configurations

| Animal |

Pellet Size |

Key Feature |

Our Die Type |

| 1. Broiler Chickens |

2-3mm |

High-protein blend |

3mm flat die |

| 2. Layer Hens |

4mm |

Calcium-enriched |

4mm ring die |

| 3. Dairy Cattle |

6-8mm |

Molasses binding |

6mm tapered die |

| 4. Beef Cattle |

8mm |

High-fiber roughage |

8mm corrugated die |

| 5. Sheep/Goats |

6mm |

Low-starch formula |

6mm flat die |

| 6. Pigs |

5mm |

Lysine-fortified |

5mm ring die |

| 7. Rabbits |

3mm |

High-roughage blend |

3mm flat die |

| 8. Ducks |

4mm |

Floating aquatic feed |

4mm ring die |

| 9. Fish |

2-5mm |

Slow-sink pellets |

5mm tapered die |

| 10. Horses |

8-10mm |

Low-sugar mix |

10mm flat die |

| 11. Ostriches |

6mm |

High-fiber pellets |

6mm corrugated die |

| 12. Game Animals |

4-6mm |

Balanced nutrients |

6mm ring die |

| 13. Pet Food |

2-3mm |

Customized recipes |

3mm flat die |

Agri 20 Pellet Machine: Material Compatibility (13 Types)

| Material Type |

Pellet Output |

Key Adaptation |

Local Use Case |

| 1. Rice Husks |

6-8mm fuel/feed pellets |

Tungsten-carbide die for abrasion resistance |

Mpumalanga biomass energy |

| 2. Corn Stalks |

8mm cattle feed |

High-pressure die (4:1 compression) |

Free State dairy farms |

| 3. Wood Shavings |

6-10mm wood pellets |

Steam conditioning at 15% moisture |

Western Cape furniture waste |

| 4. Soybean Meal |

3-5mm protein pellets |

Molasses binding (12% moisture) |

KwaZulu-Natal poultry farms |

| 5. Fish Waste |

4mm aquafeed pellets |

Double-layer conditioning |

Eastern Cape fish farms |

| 6. Vegetable Waste |

5mm compost pellets |

Low-temperature processing |

Urban organic farms |

| 7. Meat Byproducts |

6mm pet food pellets |

High-fat tolerance (≤18%) |

Johannesburg pet food co-ops |

| 8. Wheat Straw |

8mm roughage pellets |

Corrugated die for fiber binding |

Northern Cape sheep farms |

| 9. Sunflower Hulls |

4mm high-fiber feed |

Pre-crushing to 2mm particles |

Limpopo poultry |

| 10. Bamboo Chips |

10mm fuel pellets |

Extended die land length |

Coastal biomass plants |

| 11. Alfalfa Hay |

6mm equine feed |

Quick-cooling post-pelleting |

Gauteng horse stables |

| 12. Peanut Shells |

6-8mm boiler fuel |

Anti-slip auger design |

North West agro-waste |

| 13. Manure Slurry |

8mm fertilizer pellets |

Die-hole taper for binding |

Rural co-ops |

Agri 20 vs. Competing Machines (10 Comparisons)

| Tool Name |

Method |

Advantage |

Disadvantage |

Our Edge |

| 1. Flat Die Mill (FD350) |

Manual feed compression |

20% lower cost |

50kg/hr max output |

Automated feed control |

| 2. Ring Die Mill |

Industrial-scale pelleting |

1+ ton/hr capacity |

Requires 3-phase power |

Compact 380V operation |

| 3. Hammer Mill |

Crushing only |

Handles fibrous materials |

No pelleting function |

Integrated grinding-pelleting |

| 4. Fish Extruder |

High-temperature expansion |

Floating aquafeed |

3x energy consumption |

Dual feed/fuel capability |

| 5. Briquetting Press |

Hydraulic compaction |

Dense briquettes |

Slow (100kg/hr) |

Faster pellet cooling |

| 6. Manual Press |

Hand-operated |

No electricity needed |

Labor-intensive |

Motorized auger |

| 7. Industrial Pellet Line |

15-20t/h output |

Full automation |

R1.5M+ investment |

Modular scalability |

| 8. Compost Turner |

Aerobic fermentation |

Organic fertilizer prep |

No pellet shaping |

Direct manure pelleting |

| 9. Feed Mixer |

Blending only |

Uniform nutrient mix |

Additional pelleting needed |

All-in-one processing |

| 10. Diesel Pelletizer |

Off-grid operation |

No Eskom reliance |

High fuel costs |

Hybrid PTO/electric option |

10 South African Expert Reviews

| Expert Name |

Authority |

City |

Industry |

Experience |

Review |

| 1. Johan van Niekerk |

Feed Mill Director |

Pretoria |

Poultry |

22 years |

“Our Agri 20 processes 200kg/hr of sunflower hulls with ≤5% fines—unmatched for small mills.” |

| 2. Thandiwe Mbeki |

Biomass Consultant |

Cape Town |

Renewable Energy |

15 years |

“Husk pellets meet EU standards; ideal for load-shedding backup.” |

| 3. Pieter Botha |

Dairy Farm Owner |

Bloemfontein |

Livestock |

18 years |

“Corn stalk pellets cut feed costs by 40% versus commercial feed.” |

| 4. Nomsa Khumalo |

Aquafeed Specialist |

Durban |

Aquaculture |

12 years |

“Fish waste pellets improved tilapia FCR by 1.2:1.” |

| 5. Kobus Venter |

Agri-Cooperative Lead |

Limpopo |

Crop Waste |

25 years |

“Rice husk valorization added R50,000/yr revenue.” |

| 6. Annette de Wet |

Pet Food Manufacturer |

Johannesburg |

Pet Nutrition |

10 years |

“Meat-based pellets reduced preservatives by 30%.” |

| 7. Sipho Dlamini |

Organic Fertilizer Co. |

Nelspruit |

Farming |

8 years |

“Manure pellets sell for R120/bag to urban gardeners.” |

| 8. Hendrik Grobler |

Research Scientist |

Stellenbosch |

Biomass |

20 years |

“Peer-reviewed study confirmed 95% pellet durability.” |

| 9. Fatima Patel |

Feed Quality Auditor |

Pietermaritzburg |

Regulatory |

14 years |

“SANAS-certified for export-grade pellets.” |

| 10. Elias Mthembu |

Rural Energy NGO |

Mthatha |

Off-Grid |

17 years |

“PTO option powers pellets during Eskom outages.” |

Agri 20 Pellet Machine Price & South Africa Market Analysis

1. How Much Is an Agri 20 Pellet Machine? (Global Price Range & Key Models)

| Model |

Company |

Price Range (USD) |

Output (t/h) |

Key Advantages |

Limitations |

| SZLH250 |

RICHI |

7,000–7,000–15,000 |

1–2 |

Belt-driven, low noise, 35s conditioning |

Limited to small-scale farms |

| SZLH320 |

RICHI |

15,000–15,000–20,000 |

3–4 |

Gear-driven, 15% higher output |

Requires 3-phase power |

| Model 160 |

Ritlee |

12,000–12,000–18,000 |

0.15–0.2 |

PTO/electric options, local SA support |

Lower automation |

| Agricon PTO |

Agricon |

10,000–10,000–16,000 |

0.1–0.3 |

Single-phase power, African-market design |

Manual feed control |

| SZLH350 |

RICHI |

20,000–20,000–25,000 |

5–7 |

97% gear efficiency, multi-point steam |

Higher upfront cost |

2. Agri 20 Pellet Machine Price in South Africa (Localized Options)

| Supplier |

Price Range (ZAR) |

Power |

Best For |

Unique Selling Point |

| RICHI SA |

R120,000–R250,000 |

22–37kW |

Commercial feed mills |

Automated control, EU compliance |

| Ritlee |

R85,000–R150,000 |

11–22kW |

Smallholder farmers |

Local manufacturing, bush-feed adaptation |

| Agricon |

R75,000–R130,000 |

Single-phase |

Rural off-grid farms |

Trade-in program, SA-built |

| ABC Machinery |

R110,000–R200,000 |

30kW |

Biomass/fuel pellets |

Turnkey plants |

3. Ultimate Guide to Agri 20 Pellet Machine Technology in South Africa: Why We Lead the Market

| Category |

Our Innovation |

Competitor Gap |

SA Market Impact |

| Power Adaptability |

Hybrid PTO/3-phase motors |

Imported machines lack load-shedding solutions |

40% lower downtime vs. European models |

| Material Flexibility |

Processes bush feed, husks, invasive plants |

Limited to standard feedstocks |

200+ farmers using alien plants for pellets |

| Cost Efficiency |

R0.18/kWh energy use (vs. R0.25 industry avg.) |

Higher wear on imported dies |

30% ROI within 12 months |

| Automation |

IoT-enabled motor load sensors |

Manual feed rate adjustment |

15% higher output consistency |

| Local Compliance |

SANAS-certified pellets (≤7% ash) |

Non-compliant biomass exports |

EU market access for SA producers |

| After-Sales |

Johannesburg-based technicians |

4–8wk wait for foreign suppliers |

90%故障 resolved in 48hrs |

Contact Us to Become a Maikong Pellet Machine Distributor in South Africa

We welcome partnerships with ambitious distributors across South Africa to expand our network and deliver high-quality pellet machines to local farmers and businesses. Below are our key contact details for sales inquiries and dealership opportunities.

Sales & Distribution Contacts

Why Partner with Us?

- Exclusive Territory Rights: Secure distribution rights for your region.

- Local Stock Availability: Fast access to spare parts and machines in Johannesburg.

- Training & Support: Comprehensive onboarding and technical assistance.

- Competitive Margins: Attractive wholesale pricing for bulk orders.

For dealership inquiries, reach out via WhatsApp or email—we respond within 24 hours. Let’s grow Africa’s agricultural productivity together!