The MAIKONG lucerne pellet machine represents cutting-edge technology for transforming alfalfa and other forage materials into high-quality feed and fuel pellets. Engineered with precision in our SZ, GD manufacturing facilities, these machines deliver exceptional performance for South African agricultural businesses seeking reliable, efficient pelletizing solutions. With customizable configurations, superior components, and comprehensive technical support, MAIKONG stands as your trusted partner in lucerne pellet production.

MAIKONG: Your Premier Lucerne Pellet Machine Manufacturer

MAIKONG has established itself as a leading manufacturer of high-performance pellet machinery, serving the global market from our advanced production facilities in SZ, GD, China. With access to China’s premier supply chains and state-of-the-art manufacturing equipment, we deliver lucerne pellet machines that combine premium quality with competitive pricing.

Our commitment to excellence extends beyond manufacturing. We offer comprehensive customization options, allowing you to tailor your lucerne pellet machine to your specific production requirements. Whether you’re processing pure alfalfa or mixed forage materials, MAIKONG delivers solutions that maximize efficiency, durability, and return on investment.

Ready to Upgrade Your Pellet Production?

Our technical team is available to discuss your specific requirements and recommend the ideal lucerne pellet machine configuration for your operation.

Contact via WhatsApp

Superior Technical Features of MK-Lucerne Pellet Machine

MAIKONG’s lucerne pellet machines incorporate advanced engineering and premium components to deliver exceptional performance and durability. Our commitment to technical excellence ensures that your investment delivers reliable operation and superior pellet quality for years to come.

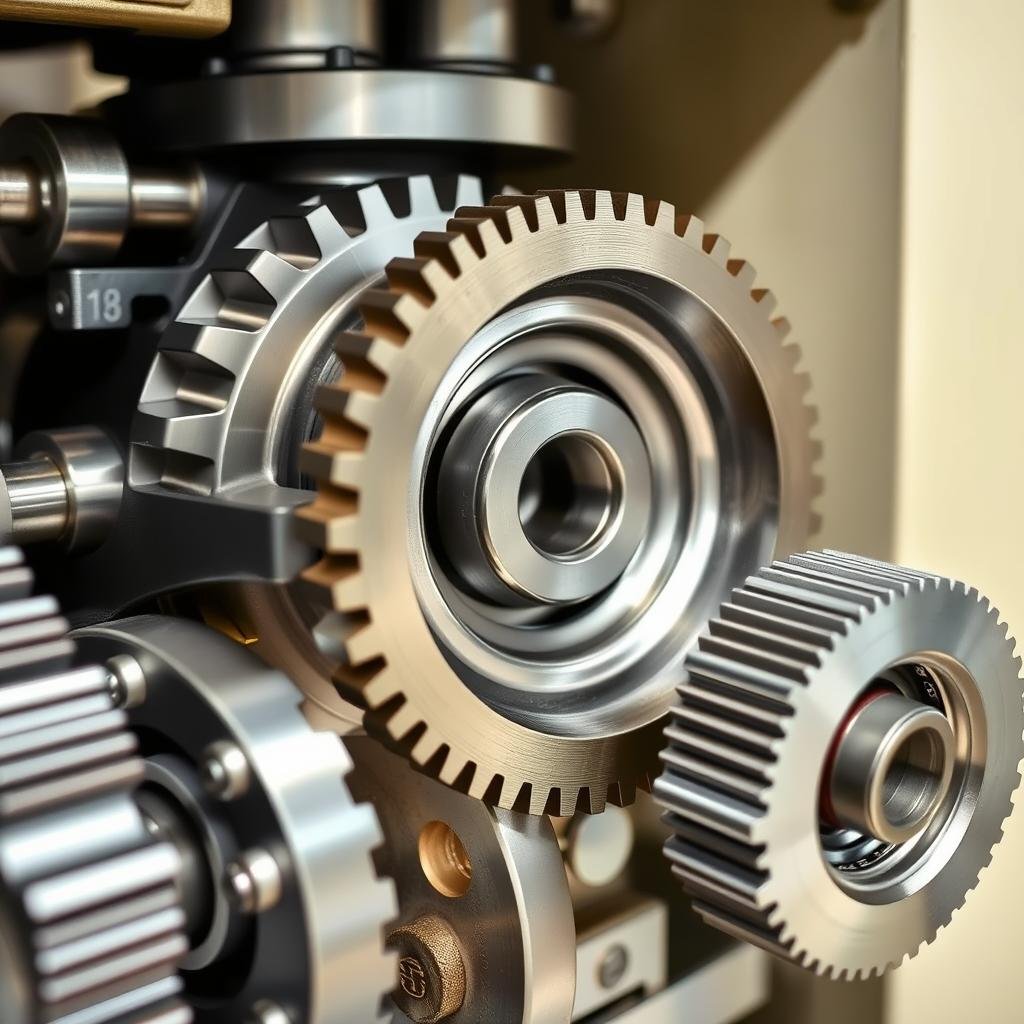

Advanced Gear Transmission System

The transmission system of our lucerne pellet machine employs precision-engineered gear technology that provides significant advantages over conventional belt-driven systems:

- Occupies minimal space while distributing force evenly across components

- Simple structure for easier operation and maintenance

- 15% higher output efficiency compared to belt-driven alternatives

- High-precision aviation-grade gear grinding technology ensures smooth operation

- Reduced noise levels for improved working environment

Versatile Ring Die Options

Our lucerne pellet machines come equipped with premium ring dies that can be customized to your specific production requirements:

- Available in various apertures ranging from φ1.5mm to φ12mm

- Multiple thickness options to optimize for different raw materials

- Manufactured from high-grade stainless steel for extended service life

- Easy replacement system for minimal downtime during changeovers

- Optimized hole patterns for maximum production efficiency with lucerne material

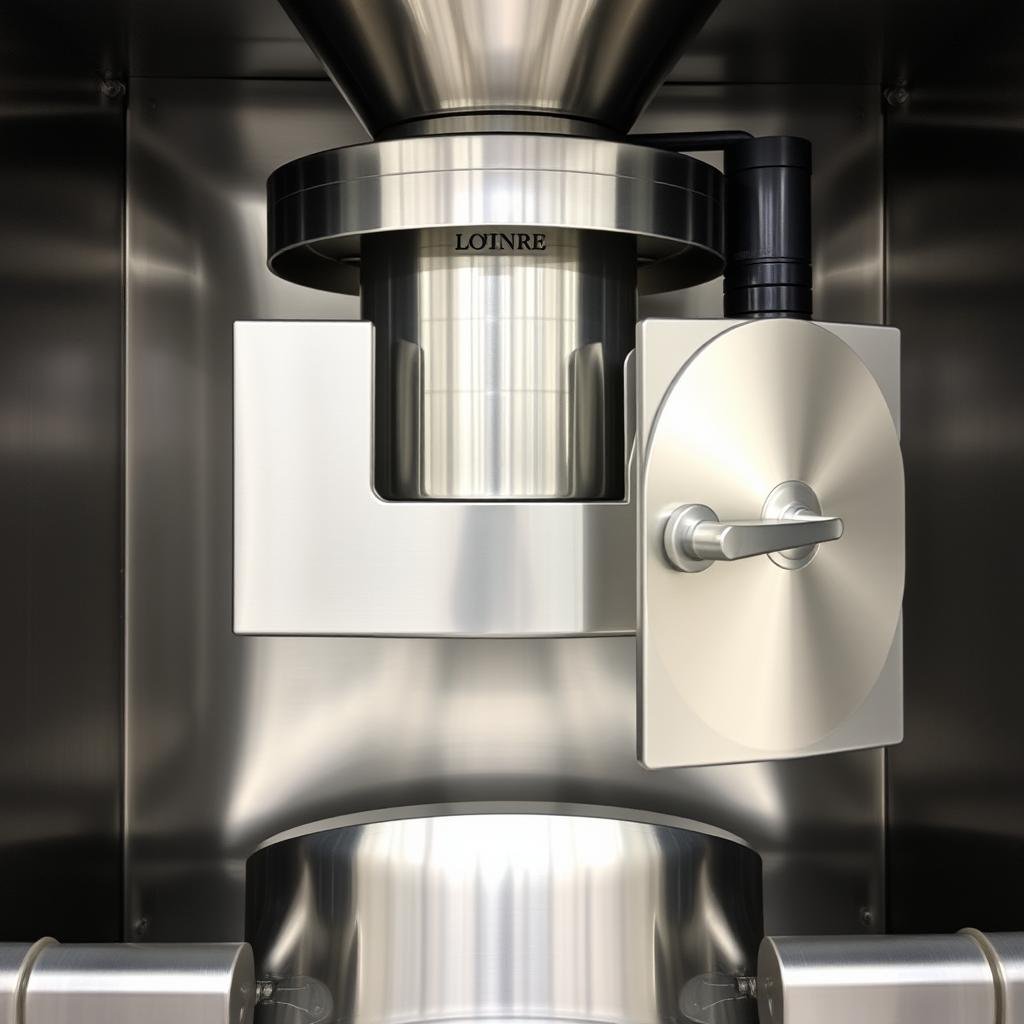

Premium Siemens Motors

MAIKONG exclusively uses genuine Siemens motors in our lucerne pellet machines, providing numerous benefits:

- Superior energy efficiency reducing operational costs

- Exceptional reliability with minimal maintenance requirements

- Low noise operation for improved working conditions

- Adjustable feeding speed for precise production control

- Extended service life compared to standard motors

Food-Grade Stainless Steel Components

Critical components of our lucerne pellet machines are constructed from premium stainless steel:

- Feeding auger, conditioner, and door cover made from SUS304 stainless steel

- Prevents contamination of raw materials due to equipment corrosion

- Significantly extended service life compared to standard materials

- Easier cleaning and maintenance for optimal hygiene

- Resistant to wear from abrasive materials like lucerne

Precision Cutter Device

Our lucerne pellet machines feature a dual-cutter system for precise pellet length control:

- Equipped with two high-grade steel cutters for clean, precise cuts

- Adjustable cutting mechanism for controlling finished pellet length

- Designed for minimal wear even with abrasive materials

- Easy access for maintenance and replacement

- Consistent pellet size for professional-grade final product

Intelligent Feeding System

The feeding system in our lucerne pellet machines offers precise control for optimal production:

- Stepless frequency conversion motor for infinitely variable speed control

- Consistent material flow for uniform pellet quality

- Automatic feed rate adjustment based on system load

- Reduced risk of blockages and system overloads

- Digital control interface for precise operation

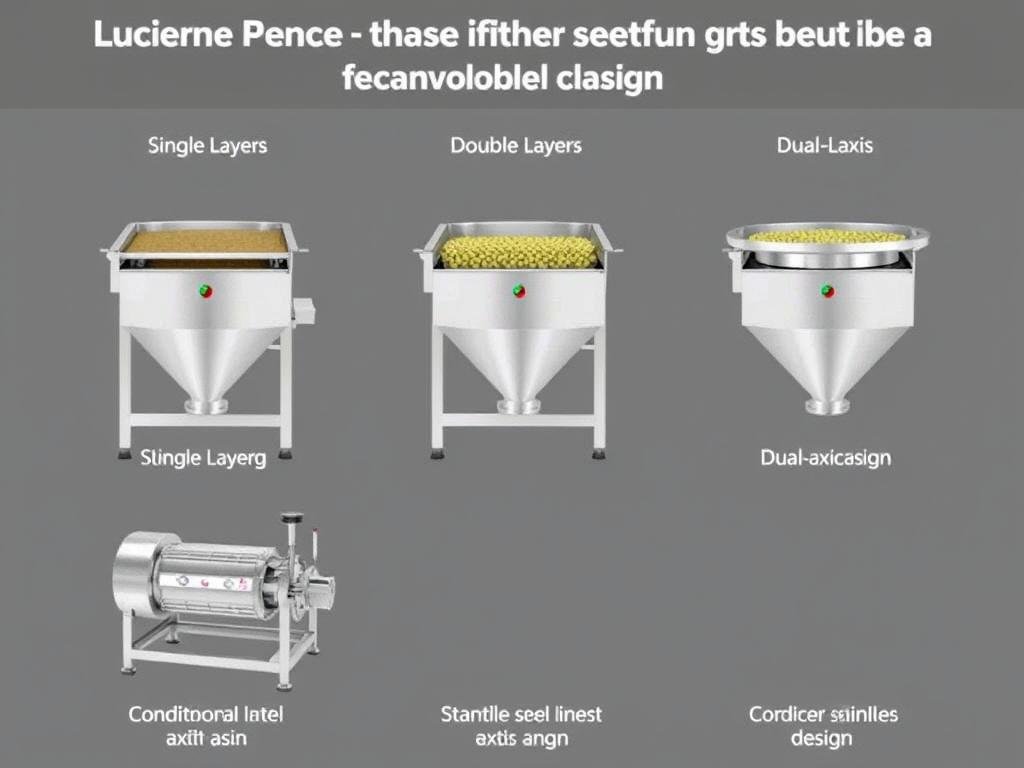

Customizable Conditioner Options

MAIKONG offers multiple conditioner configurations to match your specific production requirements:

- Single-layer conditioner for basic processing needs

- Double-layer conditioner for enhanced material preparation

- Three-layer conditioner for complex material blends

- Dual-axis differential conditioner for premium pellet quality

- Stainless steel construction for food-grade production

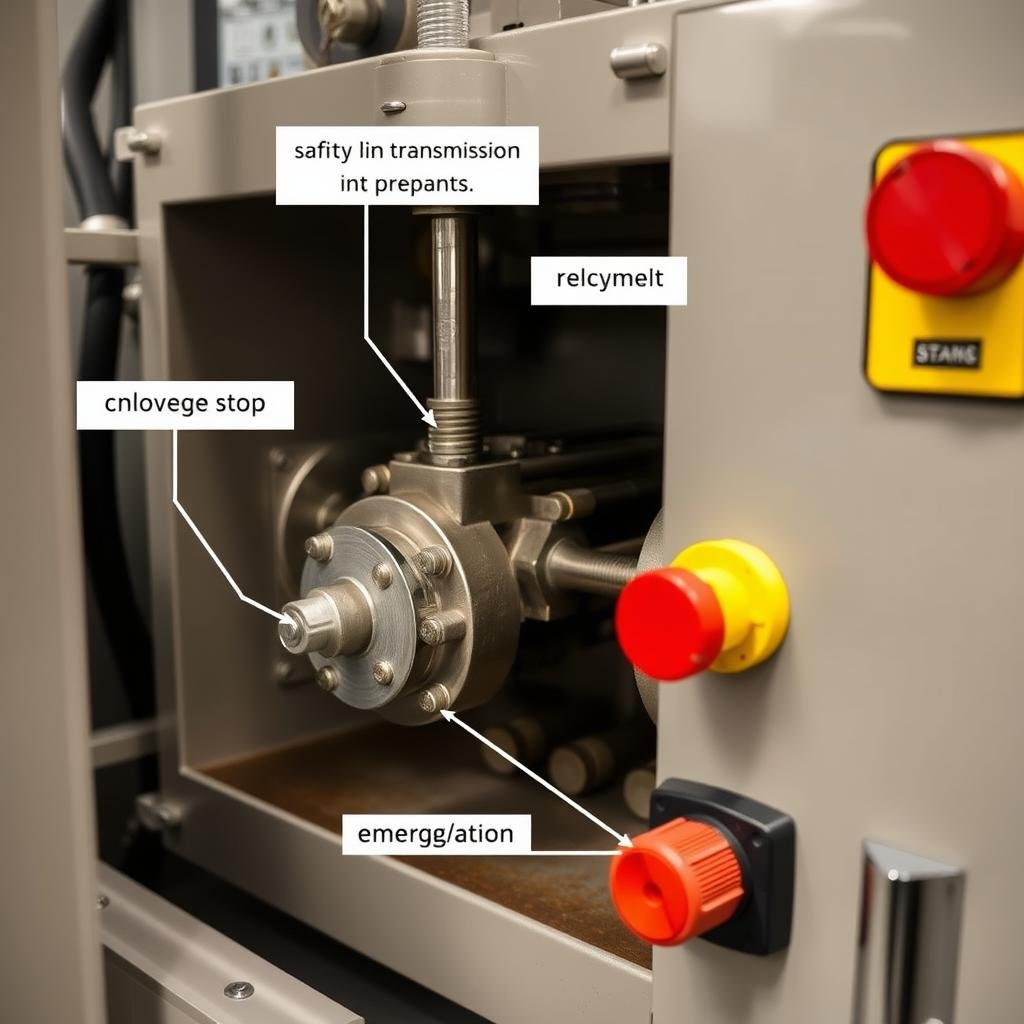

Comprehensive Safety Features

Our lucerne pellet machines incorporate multiple safety systems to protect both operators and equipment:

- Safety pin system that breaks under overload conditions to prevent damage

- Door cover equipped with travel switch that automatically powers off the main motor when opened

- Fully enclosed transmission parts to prevent operator injury

- Emergency stop buttons positioned for quick access

- Overload protection systems to prevent motor burnout

Need Technical Specifications?

Our engineering team can provide detailed technical information and customization options for your specific lucerne processing requirements.

Email Our Technical Team

MK-Lucerne Pellet Machine Specifications and Parameters

MAIKONG offers a comprehensive range of lucerne pellet machine models to accommodate various production requirements. From small agricultural operations to large-scale industrial applications, we have the perfect solution for your lucerne pelletizing needs.

| Model |

Output (t/h) |

Main Motor Power (kw) |

Feeder Power (kw) |

Conditioner Power (kw) |

Ring Die Diameter (mm) |

Finished Pellet Diameter (mm) |

| MK-SZLH250 |

1~1.5 |

22 |

1.1 |

1.5 |

250 |

2~12 |

| MK-SZLH320 |

3~4 |

37 |

1.5 |

2.2 |

320 |

2~12 |

| MK-SZLH350 |

5~6 |

55 |

1.5 |

3 |

350 |

2~12 |

| MK-SZLH420 |

10~12 |

110 |

1.5 |

7.5 |

420 |

2~12 |

| MK-SZLH508 |

15~16 |

160 |

2.2 |

11 |

508 |

2~12 |

| MK-SZLH558 |

20~22 |

185 |

2.2 |

11 |

558 |

2~12 |

| MK-SZLH678 |

30~33 |

250 |

2.2 |

11 |

673 |

2~12 |

| MK-SZLH768 |

38~40 |

315 |

2.2 |

11 |

762 |

2~12 |

Standard Equipment Configuration

- Ring die material: Premium stainless steel

- Door cover of granulation room: 6mm/SUS304

- Feed chute: 3mm/SUS304

- Gear box: HT250 high-strength alloy

- Gear: 42CrMo hardened steel

- Gear shaft: 20CrMnTi precision-machined

- Spindle: 42CrMo heat-treated

- Bearings: Imported premium quality

- Oil seals: German/Taiwan precision components

- Drive: Serpentine spring coupling system

Lucerne Pellet Machine Pricing Factors for South African Buyers

The cost of a MAIKONG lucerne pellet machine varies based on several key factors. Understanding these variables helps you select the most cost-effective solution for your specific requirements.

Production Capacity

Our lucerne pellet machines range from 1-2 T/H for small operations to 38-40 T/H for industrial-scale production. Higher capacity models naturally command higher prices due to more robust components and larger motors.

Ring Die Specifications

The ring die is a critical component affecting both price and performance. Factors include aperture size (φ2mm~φ8mm), material quality (carbon steel vs. stainless steel), and thickness. Premium stainless steel dies offer extended lifespan but at higher initial cost.

Customization Requirements

MAIKONG offers extensive customization options including specialized conditioners, unique ring die configurations, custom door opening mechanisms, and special paint finishes. Each customization affects the final price based on complexity and materials required.

Component Quality

We use premium components including Siemens motors, imported bearings, and high-grade stainless steel. While these increase initial investment, they significantly reduce maintenance costs and extend equipment lifespan, providing better long-term value.

Energy Efficiency Features

Optional energy-saving features like variable frequency drives and optimized gear ratios may increase upfront costs but deliver substantial operational savings. For operations with high electricity costs, these features typically pay for themselves within 1-2 years.

After-Sales Support Package

MAIKONG offers various service packages including installation assistance, operator training, and extended warranties. These value-added services enhance your investment protection but may affect the total package price.

Price Range Guide: MAIKONG lucerne pellet machines typically range from 7,000 USD for basic models to 100,000 USD for high-capacity industrial systems with advanced features. Contact our sales team for a precise quotation based on your specific requirements.

Request a Customized Quotation

Our sales team will provide a detailed quotation based on your specific production requirements and optional features.

Get Your Quote

Applications and Benefits of MAIKONG Lucerne Pellet Machine

The versatile MAIKONG lucerne pellet machine offers numerous applications and benefits for South African agricultural businesses. Understanding these advantages helps you maximize your return on investment.

Raw Material Versatility

While optimized for lucerne (alfalfa), our pellet machines can process a wide range of materials:

- Lucerne/alfalfa in various forms (fresh, dried, baled)

- Other forage grasses (timothy, clover, ryegrass)

- Agricultural residues (straw, hay, corn stalks)

- Wood chips and sawdust for wood pellet machine applications

- Mixed feed ingredients for complete animal nutrition

Key Benefits of Lucerne Pellet Production

Improved Storage & Transport

Converting loose lucerne into dense pellets offers significant logistical advantages:

- Reduces volume by up to 80% compared to loose material

- Increases density from 80-120 kg/m³ to 650-700 kg/m³

- Extends shelf life by reducing moisture content

- Minimizes storage space requirements

- Reduces transportation costs significantly

Enhanced Nutritional Value

The pelleting process improves the nutritional profile of lucerne:

- Preserves protein content and essential nutrients

- Improves digestibility through conditioning process

- Reduces waste during feeding (less than 5% vs. 10-15% for loose feed)

- Prevents selective feeding by animals

- Allows precise nutrient formulation with additives

Dual-Purpose Production

MAIKONG lucerne pellet machines offer versatile production capabilities:

- Produce premium animal feed pellets for livestock

- Create biomass fuel pellets for renewable energy

- Switch between production types with minimal adjustments

- Process various raw materials with the same equipment

- Adapt to changing market demands quickly

Market Applications

Animal Feed Production

Lucerne pellets serve as premium feed for various livestock:

- Dairy cattle feed for improved milk production

- Beef cattle feed for efficient weight gain

- Horse feed for performance and health

- Sheep and goat nutrition

- Rabbit and small animal feed

Biomass Fuel Production

The same equipment can produce renewable energy pellets:

- Clean-burning fuel for industrial boilers

- Residential heating pellets

- Co-firing with coal in power plants

- Carbon-neutral energy alternative

- Utilization of agricultural waste materials

“The wood pellet making machine technology we’ve incorporated into our lucerne pellet machines ensures exceptional durability and consistent pellet quality, even when processing challenging materials like lucerne with its high fiber content.”

– MAIKONG Engineering Team

Complete Lucerne Pellet Production Lines

Beyond individual machines, MAIKONG offers comprehensive turnkey solutions for lucerne pellet production. Our integrated systems ensure optimal performance at every stage of the production process.

Standard Lucerne Pellet Production Process

- Raw Material Preparation: Cleaning, drying, and initial processing of lucerne

- Grinding: Size reduction using hammer mills to optimal particle size

- Mixing: Blending with additives or other ingredients if required

- Conditioning: Steam treatment to improve binding properties

- Pelleting: Compression into dense pellets using our lucerne pellet machine

- Cooling: Reducing temperature and moisture for stable storage

- Screening: Removing fines and ensuring uniform pellet size

- Packaging: Weighing and bagging for distribution

Equipment Included in Complete Production Lines

Pre-Processing Equipment

- Bale breakers for handling compressed lucerne

- Cleaning screens for removing foreign materials

- Dryers for moisture reduction

- MK-series hammer mills for size reduction

- Material conveyors and elevators

Core Processing Equipment

- Mixing units for blending ingredients

- Conditioning chambers for steam treatment

- MK-SZLH series lucerne pellet machines

- Counter-flow coolers for pellet stabilization

- Screening systems for pellet classification

Post-Processing Equipment

- Automatic packaging systems

- Weighing and bagging stations

- Dust collection systems

- Quality control equipment

- Warehouse management solutions

Production Line Capacity Options

| Scale |

Capacity |

Total Power |

Site Requirements |

Installation Cycle |

Estimated Cost (USD) |

| Small |

1-2 T/H |

47-75 KW |

300-500m² |

7-15 Days |

10,000-50,000 |

| Medium |

3-5 T/H |

53-165 KW |

300-700m² |

15-20 Days |

50,000-120,000 |

| Large |

8-10 T/H |

125-410 KW |

800-2000m² |

45-60 Days |

150,000-300,000 |

| Industrial |

15-20 T/H |

358-620 KW |

1500-3000m² |

60-90 Days |

250,000-580,000 |

For those seeking to integrate our lucerne pellet machine with existing equipment or looking for a used wood pellet machine for sale, MAIKONG offers flexible solutions to accommodate your specific requirements and budget constraints.

Design Your Custom Production Line

Our engineering team can design a complete lucerne pellet production line tailored to your specific requirements and budget.

Discuss Your Project

Frequently Asked Questions About Lucerne Pellet Machines

What is the price range for MAIKONG lucerne pellet machines?

MAIKONG lucerne pellet machines typically range from 7,000 to 100,000 USD depending on capacity, features, and customization requirements. Small to medium capacity machines (1-5 T/H) generally range from 7,000-50,000 USD, while larger industrial models (10-40 T/H) range from 50,000-100,000 USD. For precise pricing based on your specific requirements, we recommend contacting our sales team directly.

What raw materials can be processed with your lucerne pellet machine?

Our lucerne pellet machines are versatile and can process a wide range of materials beyond lucerne/alfalfa, including:

- Various forage grasses (timothy, clover, ryegrass)

- Agricultural residues (straw, hay, corn stalks)

- Wood materials (similar to a wood pellet making machine)

- Mixed feed ingredients for complete animal nutrition

- Other biomass materials with proper preparation

If you’re uncertain whether your specific material can be processed, we offer free material testing services to determine compatibility and optimal machine configuration.

What is the typical ROI period for a lucerne pellet machine?

The return on investment for a MAIKONG lucerne pellet machine typically ranges from 6-18 months depending on several factors:

- Local raw material costs and availability

- Market prices for finished pellets in your region

- Production scale and operational hours

- Energy costs in your location

- Labor costs and operational efficiency

Our business consultants can help you develop a detailed ROI analysis based on your specific operational parameters and local market conditions.

How does the MAIKONG lucerne pellet machine compare to a standard wood pellet machine?

While our lucerne pellet machines share some technology with our wood pellet machine line, they feature several important differences:

- Specialized conditioning systems optimized for fibrous materials

- Modified compression ratios suitable for lower-density input materials

- Enhanced feeding systems to prevent bridging of lightweight materials

- Customized die configurations for optimal lucerne pellet formation

- Versatility to process both feed and fuel materials

Many of our customers successfully use our machines for both lucerne and wood pelleting with appropriate die changes and parameter adjustments.

What after-sales support does MAIKONG provide for South African customers?

MAIKONG provides comprehensive after-sales support for our South African customers:

- Remote installation guidance and commissioning support

- Comprehensive operator training via video conferencing

- 24/7 WhatsApp technical support for urgent issues

- Regular maintenance schedules and troubleshooting guides

- Prompt spare parts delivery with expedited shipping options

- Extended warranty options for additional peace of mind

Our dedicated support team ensures that your operation maintains maximum productivity with minimal downtime.

Why Choose MAIKONG for Your Lucerne Pellet Machine

MAIKONG stands as your premier partner for high-quality lucerne pellet machines and complete production solutions. With our advanced manufacturing facilities in SZ, GD, access to China’s superior supply chains, and commitment to excellence, we deliver pelleting equipment that combines premium quality with competitive pricing.

Manufacturing Excellence

Our state-of-the-art production facilities and rigorous quality control ensure that every lucerne pellet machine meets the highest standards of performance and durability. We use premium materials and components, including genuine Siemens motors and imported bearings, to deliver equipment that stands the test of time.

Customization Capabilities

We understand that every operation has unique requirements. That’s why we offer extensive customization options for our lucerne pellet machines, allowing you to tailor the equipment to your specific production needs. From specialized dies to custom conditioning systems, we can create the perfect solution for your application.

Comprehensive Support

Our commitment to your success extends beyond equipment delivery. We provide comprehensive technical support, operator training, and maintenance guidance to ensure your lucerne pellet machine operates at peak efficiency. With MAIKONG, you gain not just a supplier, but a long-term partner in your pelleting operations.

Whether you’re processing lucerne for animal feed or seeking a versatile solution that can also function as a wood pellet machine, MAIKONG delivers the technology, quality, and support you need to succeed. Contact us today to discuss your specific requirements and discover how our lucerne pellet machines can enhance your production capabilities.