Technical Specifications of MAIKONG Chicken Feed Pellet Machines

MAIKONG offers a comprehensive range of chicken feed pellet machine models to suit operations of all sizes. Our machines are engineered for maximum efficiency, durability, and ease of maintenance in the South African agricultural environment.

Technical diagram of MAIKONG’s chicken feed pellet machine components

| Model |

Power (kW) |

Capacity (kg/h) |

Pellet Size (mm) |

Dimensions (mm) |

Weight (kg) |

| MK-125 |

3 |

50-80 |

2-8 |

660×320×680 |

90 |

| MK-150 |

4 |

100-150 |

2-8 |

780×320×750 |

120 |

| MK-210 |

7.5 |

200-400 |

2-8 |

970×430×950 |

210 |

| MK-230 |

11 |

300-500 |

2-8 |

1150×480×1050 |

280 |

| MK-260 |

15 |

500-600 |

2-8 |

1250×520×1100 |

350 |

| MK-300 |

18.5 |

600-700 |

2-8 |

1350×580×1300 |

650 |

| MK-400 |

30 |

1000-1200 |

2-8 |

1670×630×1550 |

850 |

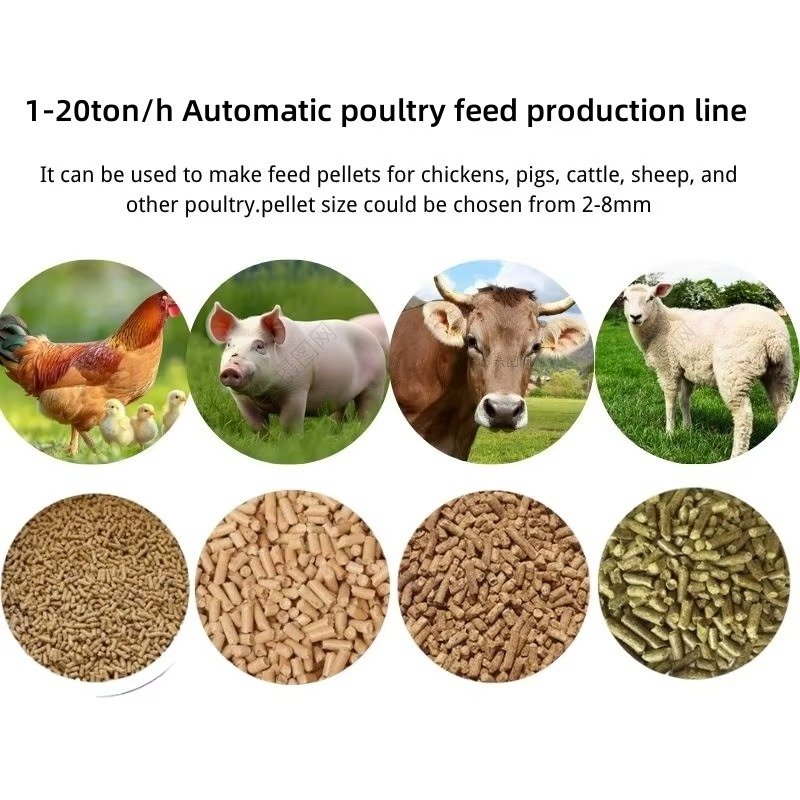

Customizable Pellet Size

Produce pellets from 2-8mm diameter to suit different poultry growth stages and nutritional requirements.

Advanced Flat Die System

Our precision-engineered flat die system ensures consistent pellet quality with minimal power consumption.

User-Friendly Controls

Simple operation with intuitive controls designed for farm environments and varying operator skill levels.

Customization Options for Your Chicken Feed Pellet Machine

At MAIKONG, we understand that every poultry operation has unique requirements. Our chicken feed pellet machine models can be customized to meet your specific needs, ensuring optimal performance and efficiency.

Die Customization

Choose from various die hole diameters (2-8mm) to produce pellets perfectly sized for your specific poultry requirements.

Power Options

Select from electric motors, diesel engines, or PTO drives based on your farm’s infrastructure and power availability.

Capacity Customization

From small 50kg/h units to industrial 1200kg/h systems, we offer the perfect capacity for your operation’s scale.

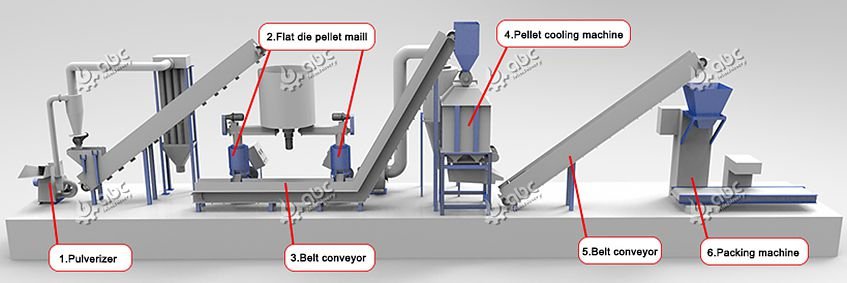

Complete Production Line Integration

Beyond standalone chicken feed pellet machine units, MAIKONG offers complete production line solutions that include:

- Feed hammer mills for ingredient grinding

- Horizontal mixers for homogeneous blending

- Pellet coolers for optimal moisture reduction

- Screening systems for pellet quality control

- Packaging systems for efficient storage

- Customized layout design for your facility

Complete MAIKONG chicken feed production line

OEM & Custom Branding Available

MAIKONG offers OEM manufacturing and custom branding options for distributors and large-scale agricultural businesses. Contact our team to discuss your specific requirements for customized equipment solutions.

Custom Solution Consultation

Speak with our engineering team about customizing a chicken feed pellet machine or complete production line for your specific requirements.

Email Our Customization Team

Comprehensive Maintenance & Support Services

MAIKONG’s commitment to your success extends beyond delivering high-quality chicken feed pellet machine equipment. We provide industry-leading support services to ensure your operation runs smoothly and efficiently.

MAIKONG’s expert technicians provide comprehensive maintenance support

24/7 Technical Support

Our dedicated technical team is available around the clock via WhatsApp to address any operational questions or troubleshooting needs.

Spare Parts Availability

We maintain a comprehensive inventory of genuine MAIKONG spare parts to minimize downtime and ensure long-term operation.

Maintenance Training

Comprehensive operator training ensures your team can perform routine maintenance and optimize machine performance.

How often should I replace the die and rollers on my chicken feed pellet machine?

Die and roller replacement intervals depend on usage intensity and materials processed. For typical poultry feed production, we recommend inspecting these components every 500-800 operating hours. With proper maintenance, dies typically last 1,000-1,500 hours before replacement, while rollers may last 1,500-2,000 hours. Our technical team can provide specific guidance based on your operation’s unique conditions.

What daily maintenance is required for optimal performance?

Daily maintenance for your MAIKONG chicken feed pellet machine includes:

- Checking and adjusting the roller-die gap

- Inspecting and cleaning the feeding system

- Lubricating all specified points according to the maintenance schedule

- Cleaning the die surface after operation

- Checking for any unusual noises or vibrations

Our comprehensive maintenance manual provides detailed instructions for all required procedures.

How can I maximize the lifespan of my chicken feed pellet machine?

To maximize equipment lifespan:

- Follow the recommended maintenance schedule precisely

- Ensure proper material preparation (correct moisture content and particle size)

- Avoid overloading the machine beyond rated capacity

- Keep the machine clean and protected from environmental elements

- Use only genuine MAIKONG spare parts for replacements

- Ensure operators are properly trained on correct usage procedures

With proper care, MAIKONG chicken feed pellet machine equipment typically provides 10+ years of reliable service.