In South Africa’s competitive poultry industry, feed quality directly impacts your bottom line. MAIKONG’s advanced broiler pellet machine technology transforms raw materials into high-quality, uniform feed pellets that improve digestion, reduce waste, and maximize growth rates. With over 20 years of specialized manufacturing experience, we deliver reliable feed processing solutions tailored to South Africa’s unique agricultural demands.

What Is a Broiler Pellet Machine and Why It’s Essential for Modern Poultry Farming

MAIKONG’s high-efficiency broiler pellet machine in operation

A broiler pellet machine is specialized equipment designed to compress and form mixed feed ingredients into cylindrical pellets that provide complete nutrition for broiler chickens. Unlike traditional mash feeds, pelletized feed offers significant advantages in digestibility, nutrient absorption, and growth performance.

Key Benefits of Using MAIKONG Pellet Machines for Broiler Feed Production

- Improved feed conversion ratio by up to 15%

- Reduced feed waste through uniform pellet size

- Enhanced digestibility through starch gelatinization

- Elimination of harmful pathogens during conditioning

- Decreased selective feeding behaviors in broilers

- Increased daily weight gain for faster market readiness

- Lower labor costs through automated feeding systems

- Reduced dust and improved barn air quality

- Better feed storage stability and shelf life

- Customizable pellet size for different growth stages

Ready to Improve Your Broiler Feed Quality?

Our technical team can help you select the right pellet machine for your production scale.

Request Free Consultation

MAIKONG: Your Trusted Broiler Pellet Machine Partner in South Africa

MAIKONG’s state-of-the-art manufacturing facility with 20+ years of expertise

For over two decades, MAIKONG has been at the forefront of pellet machine technology in South Africa. Our specialized focus on feed processing equipment has made us the preferred supplier for poultry farms, feed mills, and agricultural cooperatives across the country.

Why South African Poultry Producers Choose MAIKONG

Local Expertise

Our team understands South Africa’s unique agricultural challenges, from varying raw material quality to specific energy requirements.

Proven Reliability

MAIKONG machines are engineered for the demanding conditions of continuous commercial operation with minimal maintenance.

Comprehensive Support

From installation to operator training and ongoing technical assistance, we provide complete support throughout your equipment lifecycle.

“MAIKONG’s broiler pellet machines have transformed our feed production efficiency. The uniform pellets have improved our feed conversion ratios significantly, and their technical support has been exceptional.”

— Leading Poultry Producer, Western Cape

Technical Specifications and Features of MAIKONG Broiler Pellet Machines

Detailed component breakdown of MAIKONG broiler pellet machine

MAIKONG offers a comprehensive range of broiler pellet machines designed to meet various production capacities. From small-scale operations producing 100kg/hour to industrial systems handling 20+ tons per hour, our equipment is engineered for optimal performance and durability.

| Model |

Capacity (kg/h) |

Power (kW) |

Pellet Size (mm) |

Dimensions (mm) |

Weight (kg) |

| MKPM-150B |

90-150 |

4.0 |

2-8 |

800×350×740 |

120 |

| MKPM-200B |

200-300 |

7.5 |

2-8 |

1050×480×990 |

210 |

| MKPM-300B |

400-600 |

15.0 |

2-10 |

1240×540×1070 |

320 |

| MKPM-400B |

800-1000 |

30.0 |

2-12 |

1700×750×1400 |

720 |

Advanced Engineering Features

Precision Die and Roller System

Our machines feature high-quality alloy steel dies and precision-engineered rollers that ensure consistent pellet formation while minimizing wear. The optimized compression ratio delivers excellent pellet durability with lower energy consumption.

Intelligent Temperature Control

MAIKONG’s advanced conditioning system precisely controls steam addition and material retention time, ensuring optimal starch gelatinization and protein denaturation for maximum feed digestibility.

Energy-Efficient Drive System

Our proprietary drive technology reduces power consumption by up to 15% compared to conventional systems while maintaining production capacity, significantly lowering your operational costs.

User-Friendly Control Interface

Intuitive control panels with digital displays allow operators to easily monitor and adjust critical parameters including die temperature, motor load, and production rate in real-time.

User-friendly digital control system for precise operation

Need Technical Specifications for Your Project?

Our engineers can provide detailed technical documentation and customized solutions.

WhatsApp Technical Support

Complete Broiler Feed Production Line Solutions

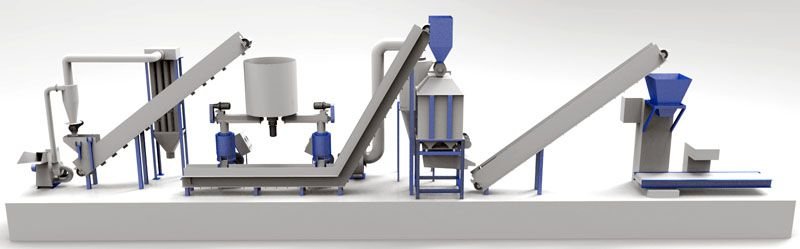

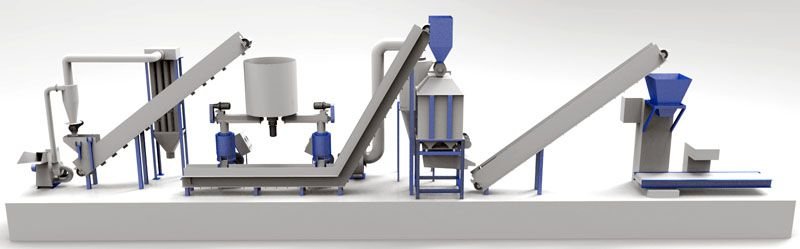

Integrated broiler feed production line from raw material to finished pellets

While the broiler pellet machine is the core component, MAIKONG provides complete feed production solutions that optimize every stage of the process. Our integrated systems ensure seamless material flow, consistent quality, and maximum efficiency.

Essential Components of a Complete Broiler Feed Production Line

Raw Material Processing

- Hammer mills for precise particle size control

- Cleaning and screening equipment

- Material handling and conveying systems

Mixing and Conditioning

- Horizontal paddle mixers for uniform blending

- Liquid addition systems for oils and enzymes

- Steam conditioning for improved pellet quality

Post-Pelleting Processing

- Counter-flow coolers for temperature stabilization

- Crumblers for starter feed production

- Screening and packaging systems

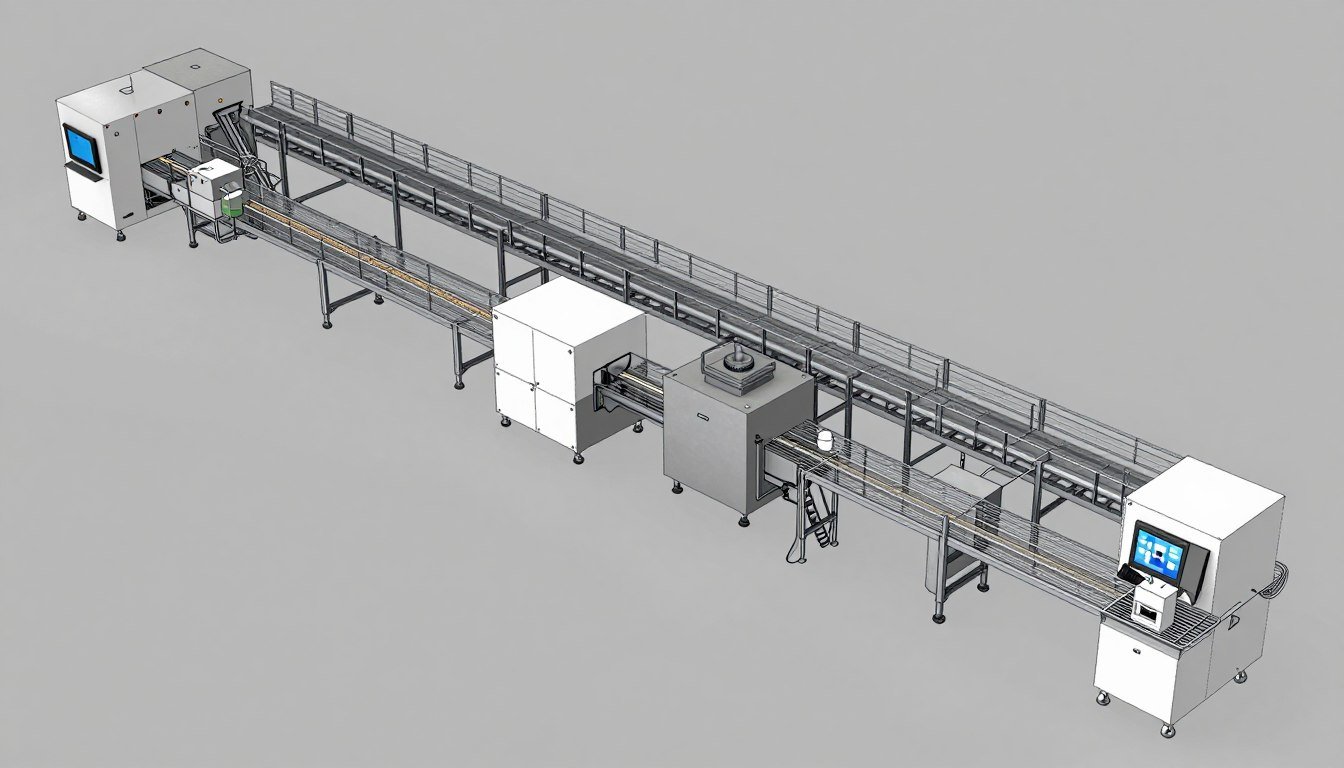

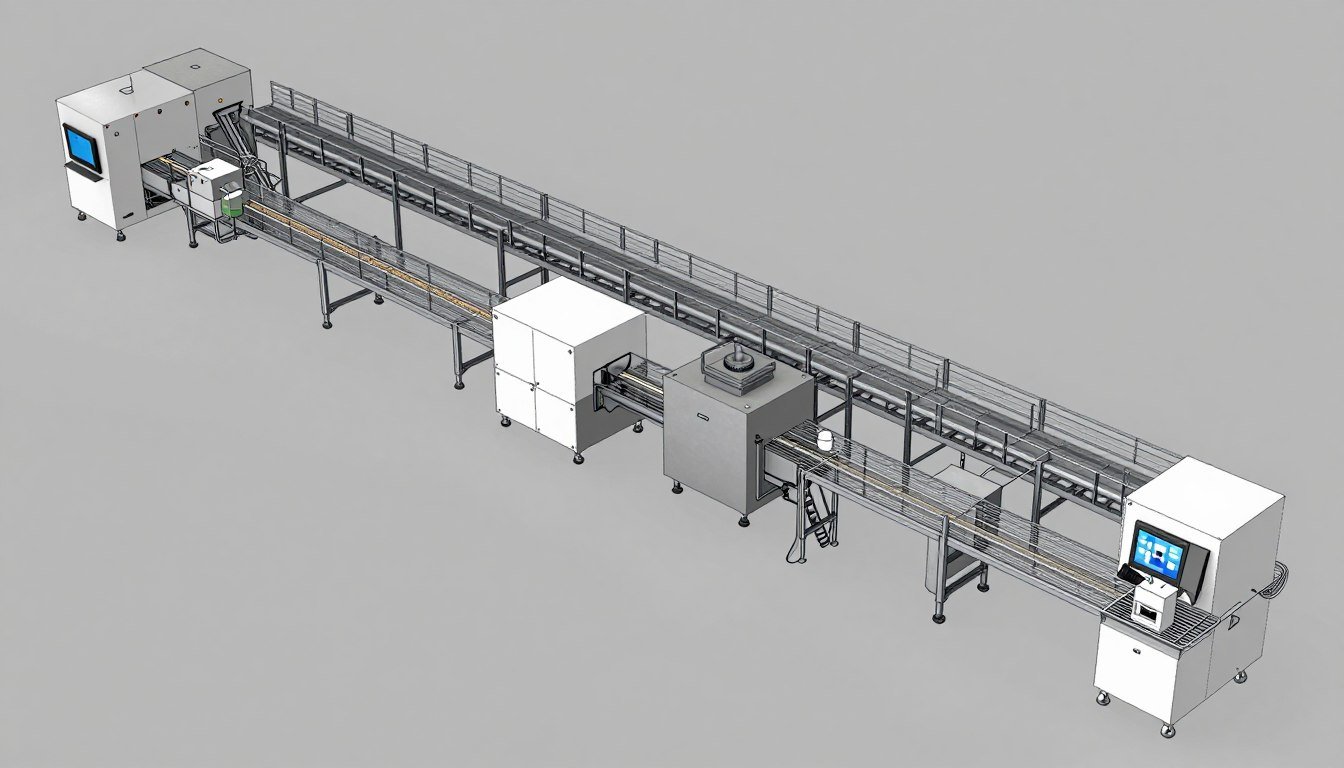

Customized Production Line Configurations

MAIKONG designs feed production systems based on your specific requirements, considering factors such as:

- Available raw materials and their characteristics

- Desired production capacity and operating schedule

- Space constraints and facility layout

- Energy availability and efficiency requirements

- Automation level and operator expertise

- Future expansion plans and scalability needs

Custom 3D layout design for optimized production flow

Planning a New Feed Mill or Upgrading Existing Equipment?

Our design team can create a customized solution that maximizes efficiency and ROI.

Email for Custom Design

Optimizing Broiler Feed Quality with MAIKONG Technology

Uniform, high-quality broiler feed pellets produced by MAIKONG equipment

The physical quality of broiler feed pellets directly impacts bird performance. MAIKONG’s advanced pelleting technology ensures optimal pellet durability, density, and nutrient preservation through precise control of critical processing parameters.

Key Processing Parameters for Superior Broiler Feed

| Parameter |

Impact on Feed Quality |

MAIKONG Advantage |

| Particle Size |

Affects pellet binding and digestibility |

Precision grinding systems with adjustable fineness control |

| Conditioning Temperature |

Influences starch gelatinization and pathogen reduction |

Multi-stage conditioning with precise temperature control |

| Die Specification |

Determines pellet size, shape, and compression ratio |

Custom die designs optimized for specific formulations |

| Cooling Efficiency |

Affects pellet hardness and moisture content |

Counter-flow cooling with adjustable retention time |

Formulation-Specific Processing Adjustments

Different feed formulations require specific processing adjustments to achieve optimal pellet quality. MAIKONG’s technical team provides expert guidance on:

- Adjusting die specifications for high-fiber formulations

- Optimizing conditioning parameters for protein-rich diets

- Calibrating compression ratios for various grain types

- Managing fat addition strategies for energy-dense feeds

- Preserving heat-sensitive additives and enzymes

- Balancing throughput with pellet quality requirements

MAIKONG technical specialist optimizing machine parameters

MAIKONG Technical Support Advantage

Our team provides ongoing technical support via WhatsApp, offering real-time troubleshooting and optimization advice. For any technical questions, simply add our support WhatsApp: +86 135 1090 7401.

Customization Options for Your Broiler Pellet Machine

Custom-engineered broiler pellet machine with client-specific modifications

MAIKONG specializes in tailoring our broiler pellet machines to meet the specific requirements of South African poultry producers. Our engineering team works closely with clients to develop customized solutions that address unique operational challenges and production goals.

Available Customization Options

Performance Customization

- Custom die configurations for specific formulations

- Enhanced conditioning systems for difficult ingredients

- Modified drive systems for varying power requirements

- Specialized cooling solutions for hot climates

Integration Customization

- Custom feeding and discharge systems

- Specialized material handling solutions

- Integration with existing equipment

- Custom control systems and automation

Operational Customization

- Alternative power configurations (diesel/PTO options)

- Mobile and stationary designs

- Enhanced wear parts for abrasive materials

- Custom safety features and operator interfaces

OEM and White Label Options

MAIKONG offers comprehensive OEM manufacturing services for distributors, agricultural equipment suppliers, and feed industry partners. Our flexible manufacturing capabilities include:

- Custom branding and color schemes

- Specialized packaging and documentation

- Modified specifications to meet market requirements

- Co-development of market-specific features

MAIKONG engineering team collaborating on custom design solutions

Need a Customized Solution?

Contact our engineering team to discuss your specific requirements and challenges.

Request Custom Quote

South African Success Stories: MAIKONG Broiler Pellet Machines in Action

Commercial poultry operation in Western Cape using MAIKONG equipment

Our broiler pellet machines have been successfully implemented across South Africa, helping poultry producers optimize their feed production and improve profitability. Here are some real-world examples of how MAIKONG equipment has transformed feed operations:

Case Study: Large-Scale Integration

Client: Commercial Poultry Operation, Gauteng

Challenge: Existing feed mill with outdated pelleting equipment experiencing high maintenance costs and inconsistent pellet quality.

Solution: MAIKONG implemented a MKPM-400B pellet machine with custom integration into the existing production line, including retrofitted conditioning and cooling systems.

Results:

- 30% increase in production capacity

- 15% reduction in energy consumption per ton

- Pellet durability improved from 82% to 94%

- Maintenance downtime reduced by 65%

Case Study: Small-Scale Efficiency

Client: Independent Broiler Farm, Eastern Cape

Challenge: High feed costs from purchased commercial feed and inconsistent quality affecting bird performance.

Solution: MAIKONG supplied a complete small-scale feed production system centered around the MKPM-200B pellet machine with integrated grinding and mixing equipment.

Results:

- Feed cost reduction of 22% compared to purchased feed

- Improved feed conversion ratio by 0.15 points

- ROI achieved within 14 months of operation

- Ability to adjust formulations based on available raw materials

“The MAIKONG broiler pellet machine has been a game-changer for our operation. The ability to produce our own high-quality feed has not only reduced our costs but also improved our birds’ performance significantly. The technical support from the MAIKONG team has been exceptional.”

— Farm Manager, KwaZulu-Natal

Comprehensive Maintenance and Support for Your Broiler Pellet Machine

MAIKONG technical specialist performing preventive maintenance

MAIKONG’s commitment to our customers extends well beyond the initial sale. We provide comprehensive technical support and maintenance services to ensure your broiler pellet machine delivers consistent performance and maximum operational life.

Our Support Services Include:

Installation & Commissioning

- Professional installation supervision

- Comprehensive system testing

- Initial calibration and optimization

- Operator training and certification

Ongoing Technical Support

- 24/7 WhatsApp technical assistance

- Remote diagnostics and troubleshooting

- Process optimization consultation

- Formulation-specific processing advice

Maintenance & Parts

- Genuine MAIKONG replacement parts

- Preventive maintenance programs

- Wear part optimization strategies

- Emergency repair service

Preventive Maintenance Recommendations

Regular maintenance is essential for optimal performance and longevity of your broiler pellet machine. MAIKONG provides detailed maintenance schedules and guidelines tailored to your specific equipment and operating conditions.

| Maintenance Task |

Frequency |

Benefit |

| Die and roller inspection |

Daily |

Ensures consistent pellet quality and prevents excessive wear |

| Bearing lubrication |

Weekly |

Prevents premature bearing failure and reduces energy consumption |

| Belt tension check |

Monthly |

Maintains proper power transmission and extends belt life |

| Complete system inspection |

Quarterly |

Identifies potential issues before they cause downtime |

WhatsApp Technical Support

MAIKONG provides immediate technical assistance via WhatsApp. Our experienced technicians can help troubleshoot issues, optimize performance, and provide maintenance guidance in real-time. Add our technical support WhatsApp: +86 135 1090 7401

Choose MAIKONG for Your South African Broiler Pellet Machine Needs

MAIKONG pellet machines ready for delivery to South African customers

With over 20 years of specialized experience in feed processing equipment, MAIKONG has established itself as South Africa’s trusted partner for high-quality broiler pellet machines and complete feed production solutions. Our commitment to excellence, technical innovation, and customer support has made us the preferred choice for poultry producers across the country.

Why Make MAIKONG Your Feed Equipment Partner:

- Proven reliability in South African operating conditions

- Comprehensive technical support and training

- Extensive customization capabilities

- Industry-leading energy efficiency

- Complete turnkey solutions from design to installation

- Genuine parts and maintenance services

- Competitive pricing and flexible financing options

- Continuous innovation and technology development

Ready to Optimize Your Broiler Feed Production?

Contact MAIKONG today to discuss your specific requirements and discover how our broiler pellet machines can transform your operation.

Visit our website for more information: https://pelletmachine.co.za/

Frequently Asked Questions About Broiler Pellet Machines

What size broiler pellet machine is right for my operation?

The appropriate machine size depends on your daily feed requirements, operating schedule, and growth plans. As a general guideline, calculate your maximum daily feed requirement and choose a machine that can produce this amount in 6-8 hours of operation. MAIKONG offers models ranging from 100kg/hour to 20+ tons/hour to suit operations of all sizes.

What power options are available for MAIKONG broiler pellet machines?

MAIKONG offers multiple power configurations including three-phase electric, diesel engine, PTO drive, and hybrid systems. Our technical team can recommend the most suitable option based on your location’s power availability, reliability, and cost considerations.

How does pelleted feed improve broiler performance compared to mash?

Pelleted feed typically improves feed conversion ratio by 5-15% compared to mash through several mechanisms: reduced selective feeding, decreased feed wastage, improved digestibility through starch gelatinization, and increased feed intake. These benefits translate to faster growth rates, more uniform flocks, and ultimately higher profitability.

What maintenance is required for a broiler pellet machine?

Regular maintenance includes daily inspection of dies and rollers, weekly lubrication of bearings and moving parts, monthly checking of belt tension and alignment, and quarterly comprehensive inspection of all systems. MAIKONG provides detailed maintenance schedules and training to ensure optimal performance and longevity.