In South Africa’s competitive poultry industry, efficient feed production is the cornerstone of profitability. MAIKONG’s 4-ton broiler pellet machine represents the pinnacle of feed processing technology, designed specifically for high-volume operations that demand reliability, efficiency, and consistent pellet quality. With over 20 years of manufacturing expertise, we’ve engineered our machines to withstand the unique challenges of the South African agricultural environment while delivering superior performance that directly impacts your bottom line.

Why Our Broiler Pellet Machine 4 Ton Transforms Poultry Operations

The MAIKONG 4-ton broiler pellet machine delivers transformative benefits that directly address the challenges faced by South African poultry operations. Our high-capacity system processes up to 4 tons of feed per hour, dramatically reducing production time while maintaining optimal pellet quality. This efficiency translates to lower operational costs and increased production capacity – critical advantages in today’s competitive market.

Superior Feed Quality for Better Bird Performance

Our advanced die and roller technology ensures consistent pellet density and durability, resulting in reduced feed waste and improved feed conversion ratios. The precision engineering of our broiler pellet machine maintains nutritional integrity throughout the pelleting process, contributing to healthier birds and faster growth rates.

Engineered for South African Conditions

Unlike imported machines that struggle with local power fluctuations and climate conditions, MAIKONG’s 4-ton broiler pellet machine is specifically designed for the South African environment. Our robust construction and adaptive control systems ensure reliable operation even during challenging conditions, minimizing costly downtime.

Ready to Revolutionize Your Feed Production?

Join the growing number of South African poultry operations upgrading to MAIKONG’s high-efficiency feed processing technology.

Request Your Custom Quote Today

Technical Specifications of Our Premium Broiler Pellet Machine 4 Ton Model

The MAIKONG broiler pellet machine 4 ton model combines cutting-edge technology with robust construction to deliver industry-leading performance. Every component is engineered for durability and efficiency, ensuring your investment delivers maximum return through years of reliable operation.

| Specification |

Details |

| Production Capacity |

3-4 tons per hour |

| Main Motor Power |

110-160 kW |

| Die Diameter |

508mm |

| Pellet Diameter Range |

2-12mm (adjustable) |

| Machine Weight |

Approximately 2,900kg |

| Dimensions (L×W×H) |

2800×1600×2200mm |

| Control System |

PLC with touchscreen interface |

| Lubrication System |

Automatic centralized lubrication |

Advanced Features for Optimal Performance

- Precision-engineered die and roller assembly for consistent pellet quality

- Variable frequency drive for optimal energy efficiency

- Advanced force-feeding system for uniform material distribution

- Automatic die and roller gap adjustment

- Overload protection system to prevent equipment damage

- High-efficiency cooling system for continuous operation

- Quick-change die system for minimal downtime during maintenance

Need Technical Specifications for Your Specific Application?

Our engineering team can provide detailed specifications and customization options tailored to your production requirements.

Email Our Technical Team

Versatile Applications of Our Broiler Pellet Machine 4 Ton Model

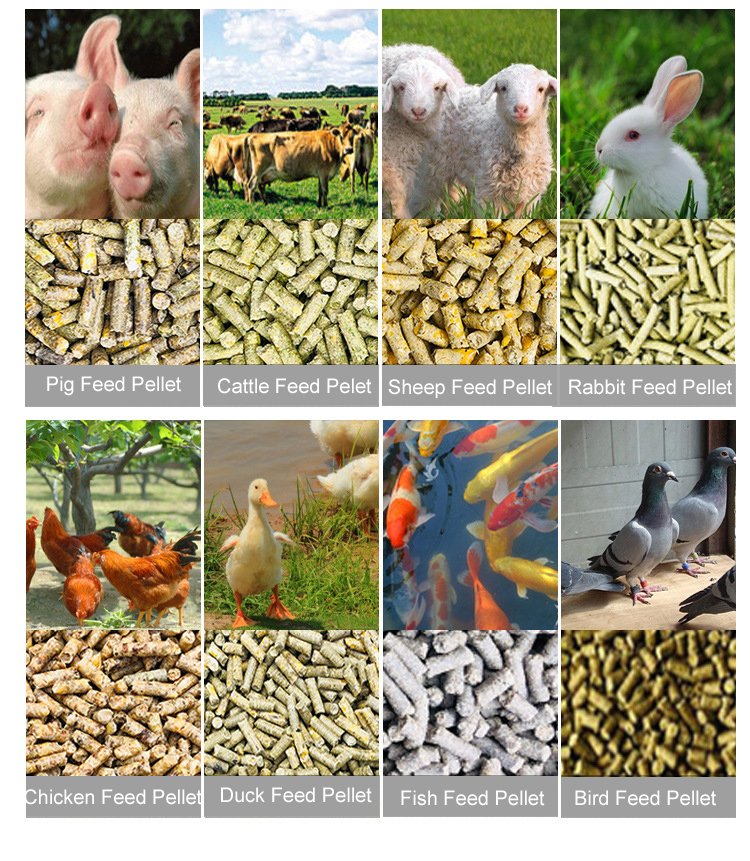

While designed primarily for broiler feed production, the MAIKONG 4-ton broiler pellet machine excels across a wide range of applications. Its versatile design and adjustable parameters make it suitable for various feed formulations and pellet specifications, providing exceptional value for diversified agricultural operations.

Broiler Feed Production

Optimized for high-volume broiler operations, our machine produces uniform, high-quality pellets that maximize feed conversion and growth rates. The adjustable die system accommodates different pellet sizes for starter, grower, and finisher feeds.

Layer Feed Processing

The precision control systems allow for the careful processing of layer feed formulations, preserving critical nutrients while creating pellets with ideal hardness and durability for optimal egg production performance.

Multi-Species Feed Production

Beyond poultry, our 4-ton pellet machine efficiently processes feed for cattle, sheep, pigs, and other livestock, making it an ideal solution for diversified farming operations or commercial feed mills serving multiple markets.

Feed Processing Capabilities

| Feed Type |

Recommended Pellet Size |

Production Capacity |

Key Benefits |

| Broiler Starter |

2-2.5mm |

3.5-4 tons/hour |

Improved digestibility, reduced waste |

| Broiler Grower |

3-3.5mm |

3.5-4 tons/hour |

Optimal feed conversion, uniform growth |

| Broiler Finisher |

3.5-4mm |

3.5-4 tons/hour |

Maximum weight gain, improved meat quality |

| Layer Feed |

3-4mm |

3-3.5 tons/hour |

Enhanced egg production, shell quality |

| Cattle Feed |

6-10mm |

3-3.5 tons/hour |

Reduced sorting, improved rumination |

Complete Feed Production Solutions Beyond the Broiler Pellet Machine

At MAIKONG, we understand that a broiler pellet machine is just one component of an efficient feed production system. That’s why we offer comprehensive solutions that integrate seamlessly with your existing setup or provide complete turnkey installations for new operations.

Our Comprehensive Product Range

Feed Pellet Machines

- Poultry Feed Pellet Machines

- Cattle Feed Pellet Machines

- Pig Feed Pellet Machines

- Sheep Feed Pellet Machines

- Ruminant Feed Pellet Machines

Explore Feed Pellet Machines

Wood Pellet Machines

- Sawdust Pellet Mills

- Biomass Pellet Mills

- Straw Pellet Machines

- Wood Chip Pellet Machines

- Industrial Wood Pellet Lines

Explore Wood Pellet Machines

Fertilizer Pellet Machines

- Organic Fertilizer Pelletizers

- Compound Fertilizer Machines

- Manure Pellet Machines

- Bio-Fertilizer Processing Lines

- Industrial Fertilizer Plants

Explore Fertilizer Machines

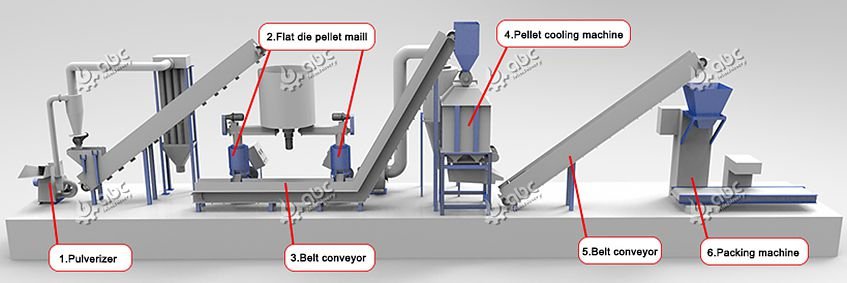

Complete Production Lines

MAIKONG offers turnkey solutions for complete feed production facilities. Our engineering team designs integrated systems that optimize workflow, maximize efficiency, and ensure consistent product quality throughout the entire production process.

Pre-Processing Equipment

- Raw material receiving systems

- Storage silos and bins

- Cleaning and sorting equipment

- Grinding and milling systems

- Precision batching and weighing

- Mixing and conditioning units

Post-Processing Equipment

- Cooling and drying systems

- Screening and sorting equipment

- Quality control instrumentation

- Packaging and bagging systems

- Storage and handling solutions

- Automation and control systems

Need a Complete Feed Production Solution?

Our engineering team can design a custom system tailored to your specific production requirements and facility constraints.

Discuss Your Project on WhatsApp

Customization Options for Your Broiler Pellet Machine 4 Ton

At MAIKONG, we understand that every feed operation has unique requirements. Our broiler pellet machine 4 ton models can be customized to meet your specific production needs, raw material characteristics, and facility constraints.

Die and Roller Customization

- Custom die hole patterns and sizes

- Specialized alloy compositions for different materials

- Optimized compression ratios for specific formulations

- Wear-resistant coatings for extended service life

Control System Options

- Basic manual control systems

- Semi-automated operation interfaces

- Fully automated PLC control systems

- Remote monitoring and diagnostics capabilities

Integration Features

- Custom input/output configurations

- Specialized material handling adaptations

- Facility-specific mounting and installation

- Compatibility with existing equipment

OEM and White Label Options

MAIKONG offers comprehensive OEM manufacturing services for distributors, equipment suppliers, and feed industry brands. Our state-of-the-art production facilities can manufacture broiler pellet machines and complete feed processing lines to your exact specifications, with your branding and design requirements.

OEM Partnership Benefits

- Access to proven, reliable equipment designs

- Customized branding and appearance

- Flexible production quantities

- Comprehensive technical documentation

- Dedicated support for your technical team

- Competitive pricing for distribution markets

OEM Requirements

- Minimum order quantities apply

- Lead time of 30-45 days for customized units

- Technical specification alignment required

- Distribution territory agreements

- Compliance with local certification standards

- After-sales service capability

Interested in OEM or Customization Options?

Contact our business development team to discuss your specific requirements and explore partnership opportunities.

Email for OEM Inquiries

Comprehensive Support for Your Broiler Pellet Machine Investment

When you choose a MAIKONG broiler pellet machine 4 ton model, you’re not just purchasing equipment – you’re gaining a dedicated partner committed to your operational success. Our comprehensive support services ensure you maximize the return on your investment through optimal performance and minimal downtime.

Installation and Commissioning

- Professional installation by factory-trained technicians

- Comprehensive site preparation guidance

- Thorough system testing and calibration

- Integration with existing equipment and systems

- Operator training during commissioning

Training and Knowledge Transfer

- Hands-on operator training programs

- Maintenance staff technical training

- Comprehensive operation manuals

- Troubleshooting guides and resources

- Process optimization consultation

Ongoing Technical Support

MAIKONG provides responsive technical support through multiple channels to ensure your broiler pellet machine operates at peak efficiency. Our technical team is available to assist with troubleshooting, maintenance advice, and optimization recommendations.

WhatsApp Technical Support: For immediate assistance with technical issues, add our support team on WhatsApp: +86 135 1090 7401. Our engineers can provide real-time guidance, including video consultations for complex issues.

Maintenance Support

- Preventive maintenance schedules

- Wear part replacement guidance

- Performance optimization advice

- Troubleshooting assistance

- Software updates and upgrades

Spare Parts Service

- Genuine factory replacement parts

- Fast shipping options for critical components

- Comprehensive parts inventory

- Wear part kits for scheduled maintenance

- Long-term parts availability guarantee

Choose MAIKONG for Your Broiler Pellet Machine 4 Ton Needs

With over 20 years of specialized experience in pellet machine manufacturing, MAIKONG has established itself as South Africa’s premier provider of high-capacity feed processing equipment. Our broiler pellet machine 4 ton models represent the culmination of decades of engineering refinement, customer feedback, and technological advancement.

By choosing MAIKONG, you’re partnering with a company that understands the unique challenges of South African poultry operations and has developed equipment specifically optimized for local conditions. Our commitment to quality, reliability, and customer success drives everything we do – from initial design to ongoing support.

4.8

Customer Satisfaction

Equipment Reliability

4.8/5

Production Efficiency

4.7/5

Value for Investment

4.7/5

Ready to Upgrade Your Feed Production Capabilities?

Contact MAIKONG today to discuss your specific requirements and discover how our broiler pellet machine 4 ton models can transform your operation.

Email: Lucy@pelletmachine.co.za

Website: https://pelletmachine.co.za/