South Africa Top pellet machine, animal feed pellet machine Manufacturer

Diesel vs. Electric Animal Feed Pellet Machine: Solving South Africa’s Load Shedding Challenges

December 22, 2025

The Impact of Load Shedding on South African Feed Production

Load shedding continues to disrupt South African agriculture, with feed production particularly vulnerable to power interruptions. When electricity fails, the entire production chain suffers—from grinding raw materials to the critical pelleting process. For livestock operations, this means potential feed shortages, compromised feed quality, and increased operational costs.

Load shedding disrupts feed production schedules, creating costly downtime for agricultural businesses

According to recent industry reports, agricultural operations experience an average of 4-6 hours of power outages during peak load shedding periods. For feed producers, this translates to:

- Production losses of 20-30% during affected periods

- Increased feed costs due to inefficient batch processing

- Potential equipment damage from sudden power interruptions

- Compromised feed quality when production processes are interrupted

Don’t Let Load Shedding Disrupt Your Feed Production

MAIKONG offers specialized solutions designed for South Africa’s energy challenges. Our experts can help you select the right power configuration for your operation.

Diesel vs. Electric Animal Feed Pellet Machine: A Comprehensive Comparison

When selecting an animal feed pellet machine for South African conditions, understanding the fundamental differences between diesel and electric models is crucial for making an informed decision that aligns with your operational needs.

Diesel-Powered Advantages

- Complete independence from the electrical grid

- Consistent operation during load shedding periods

- Mobility for remote farm locations without reliable electricity

- No need for expensive backup power systems

- Typically higher torque for processing difficult materials

Diesel-Powered Limitations

- Higher fuel and maintenance costs over time

- Greater noise levels during operation

- Regular fuel supply logistics required

- Environmental considerations (emissions)

- More complex maintenance requirements

Electric-Powered Advantages

- Lower operational costs when grid power is available

- Reduced noise levels for better working environment

- Simpler maintenance requirements

- Cleaner operation with no direct emissions

- More precise control of processing parameters

Electric-Powered Limitations

- Vulnerable to load shedding without backup systems

- Additional investment required for generators/inverters

- Potential for damage from power fluctuations

- Less suitable for remote locations with poor grid access

- Startup power requirements can be challenging

Operational Cost Comparison

| Factor | Diesel-Powered | Electric-Powered |

| Initial Investment | 15-25% higher | Lower base cost |

| Hourly Operating Cost | R120-180/hour | R60-90/hour (when grid available) |

| Maintenance Frequency | Every 200-300 operating hours | Every 500-600 operating hours |

| Annual Maintenance Cost | R15,000-25,000 | R8,000-15,000 |

| Expected Lifespan | 8-12 years | 10-15 years |

MAIKONG diesel animal feed pellet machine maintaining production during load shedding periods

The ideal solution often depends on your specific operational context. Many South African businesses are now adopting hybrid approaches or selecting models that can be adapted to both power sources as conditions change.

Need Help Choosing the Right Power Option?

Our technical team can analyze your production requirements and load shedding patterns to recommend the optimal solution.

MAIKONG’s Specialized Solutions for South African Conditions

With over two decades of experience in pellet machine manufacturing, MAIKONG has developed specialized configurations that address South Africa’s unique energy challenges. Our approach goes beyond simply offering standard diesel or electric models—we engineer solutions that provide operational continuity regardless of grid conditions.

Hybrid Power Systems

MAIKONG’s hybrid animal feed pellet machine allows seamless switching between power sources

Our innovative hybrid systems allow for seamless switching between power sources, providing the best of both worlds. These systems feature:

- Quick-change power transmission systems

- Automated switchover capabilities during power interruptions

- Optimized performance regardless of power source

- Reduced transition time between power modes

Load Shedding-Resistant Electric Models

For operations that prefer electric power, our load shedding-resistant models incorporate:

- Power stabilization systems to protect against surges

- Energy-efficient motors that reduce overall consumption

- Compatibility with solar and battery backup systems

- Soft-start technology to reduce startup power requirements

MAIKONG electric models can be integrated with renewable energy systems for uninterrupted operation

Heavy-Duty Diesel Configurations

Our diesel-powered systems are engineered specifically for South African conditions:

- Fuel-efficient engines that reduce operational costs

- Enhanced cooling systems for high-temperature environments

- Extended service intervals compared to standard models

- Dust protection features for harsh farm conditions

Small-Scale Solutions

Compact diesel and electric models producing 50-150 kg/hour, ideal for smaller livestock operations and game farms.

Medium Production

Mid-range systems producing 200-500 kg/hour, perfect for medium-sized farms and cooperative facilities.

Industrial Capacity

High-output models producing 600-1000+ kg/hour for commercial feed mills and large agricultural operations.

South African Success Stories: Overcoming Load Shedding Challenges

Case Study: Western Cape Dairy Operation

A large dairy farm in the Western Cape was experiencing significant production disruptions during Stage 4 load shedding, with feed shortages affecting milk production. After consulting with MAIKONG’s technical team, they implemented a hybrid animal feed pellet machine with quick-switch capabilities.

Results:

- Maintained 100% feed production continuity despite 6-hour daily outages

- Reduced operational costs by 22% compared to their previous generator-only backup

- Achieved ROI within 14 months through improved operational efficiency

Western Cape dairy operation maintaining feed production with MAIKONG’s hybrid solution

Case Study: Mpumalanga Poultry Cooperative

A cooperative of poultry farmers in Mpumalanga was struggling with inconsistent feed quality due to interrupted production cycles. MAIKONG provided a diesel-powered animal feed pellet machine with enhanced efficiency features.

Results:

- Standardized feed quality led to 8% improvement in poultry growth rates

- Reduced feed waste by 15% through consistent pellet production

- Enabled 24/7 production capability regardless of local grid conditions

Customization Options for South African Requirements

MAIKONG understands that every agricultural operation has unique requirements. Our customization capabilities ensure that your animal feed pellet machine is perfectly aligned with your specific needs:

Production Customization

- Output capacity tailored to your volume requirements

- Die configurations for specific feed formulations

- Pellet size options (3mm-8mm) for different livestock

- Custom feeding and discharge systems

Power System Customization

- Hybrid power configurations for operational flexibility

- Solar integration capabilities for sustainable operation

- Generator compatibility engineering

- Power stabilization systems for grid fluctuations

MAIKONG’s technical team customizing equipment to meet specific South African requirements

Need a Customized Solution?

Our engineering team can develop a tailored configuration that addresses your specific production requirements and energy challenges.

Technical Specifications: MAIKONG Animal Feed Pellet Machine Range

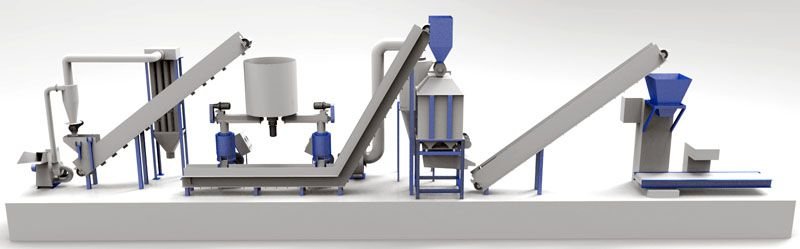

MAIKONG offers a comprehensive range of animal feed pellet machines suitable for various production scales, from small farm operations to industrial feed mills.

| Model | Power Options | Capacity (kg/h) | Pellet Size (mm) | Dimensions (m) | Suitable For |

| MK-125 | Electric 3kW / Diesel 4HP | 50-80 | 2-8 | 0.7×0.4×0.8 | Small farms, game reserves |

| MK-150 | Electric 4kW / Diesel 5.5HP | 100-150 | 2-8 | 0.8×0.4×0.9 | Medium farms, small cooperatives |

| MK-230 | Electric 11kW / Diesel 15HP | 300-500 | 2-10 | 1.2×0.6×1.1 | Large farms, commercial operations |

| MK-300 | Electric 18.5kW / Diesel 25HP | 600-800 | 2-12 | 1.4×0.7×1.3 | Feed mills, industrial applications |

| MK-400 | Electric 30kW / Diesel 40HP | 1000-1200 | 2-12 | 1.7×0.8×1.5 | Large commercial feed production |

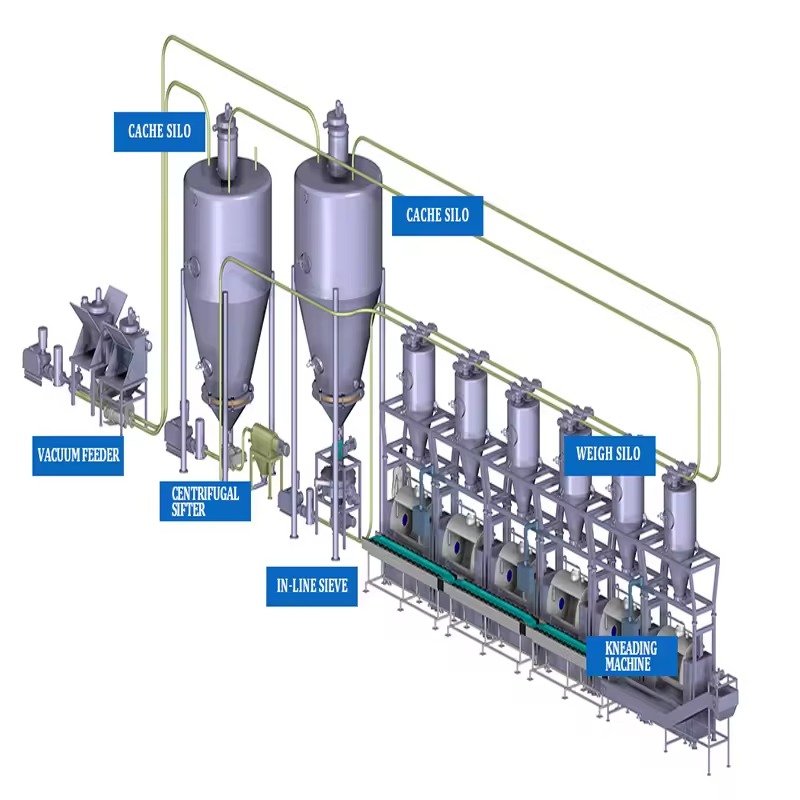

Technical diagram of MAIKONG animal feed pellet machine showing key components

All MAIKONG models feature:

- Hardened steel dies and rollers for extended service life

- Sealed bearing design to prevent contamination

- Safety systems including overload protection

- Easy maintenance access points

- Compatible with a wide range of raw materials including grains, grass, and agricultural by-products

Various feed pellet types produced by MAIKONG machines for different livestock requirements

Why Choose MAIKONG for South African Feed Production

MAIKONG’s state-of-the-art manufacturing facility

- 20+ Years of Expertise: Two decades of specialized experience in pellet machine technology

- South African Focus: Solutions specifically engineered for local conditions and challenges

- Comprehensive Support: Technical assistance via WhatsApp, email, and phone

- Customization Capabilities: Tailored solutions for specific operational requirements

- Quality Components: Premium materials ensuring durability in demanding environments

- Energy Efficiency: Optimized designs that reduce operational costs

Contact MAIKONG for Your South African Feed Production Solution

Ready to overcome load shedding challenges and optimize your feed production? MAIKONG’s team of experts is ready to help you select the ideal animal feed pellet machine configuration for your specific needs.

Technical Support

Get immediate assistance with technical questions and operational guidance.

Customization & Orders

Discuss custom requirements, place orders, or inquire about OEM opportunities.

Direct Contact

Speak directly with our South African team for immediate assistance.

MAIKONG’s technical team providing on-site support for equipment installation

Ready to Solve Your Load Shedding Challenges?

Contact MAIKONG today for a customized solution that ensures continuous feed production regardless of South Africa’s power situation.

Ensuring Feed Production Continuity in South Africa

The choice between diesel and electric animal feed pellet machines is critical for South African agricultural operations facing ongoing load shedding challenges. MAIKONG’s specialized solutions offer the reliability, efficiency, and adaptability needed to maintain production regardless of grid conditions.

With over 20 years of industry experience and a deep understanding of South Africa’s unique challenges, MAIKONG is committed to providing customized solutions that optimize your feed production capabilities while minimizing the impact of power interruptions.

Contact our team today to discuss how we can help you implement a load shedding-resistant feed production system tailored to your specific operational requirements.

Contact us online by Whatsapp: