South Africa Top pellet machine, animal feed pellet machine Manufacturer

Cost Analysis: Setting Up a Commercial Feed Mill in Lagos

December 25, 2025

Lagos Feed Mill Market: Demand and Opportunity

The feed production industry in Lagos continues to experience robust growth, driven by increasing protein consumption and expansion of commercial farming operations. Understanding the market dynamics is crucial before investing in a feed mill venture.

Modern commercial feed mill facility in Lagos

Growing Demand Factors

- Expanding poultry and livestock sectors requiring quality feed

- Rising aquaculture production with specialized feed needs

- Increasing consumer preference for protein-rich diets

- Government initiatives supporting agricultural development

- Growing awareness of feed quality’s impact on animal productivity

Market Challenges

- Fluctuating raw material prices affecting production costs

- Competition from established feed producers

- Infrastructure limitations in some areas

- Energy supply inconsistencies affecting operations

- Initial capital investment requirements

Initial Investment Breakdown for a Commercial Feed Mill

Setting up a commercial feed mill in Lagos requires careful financial planning. The initial investment varies based on production capacity, technology level, and automation degree. Below is a detailed breakdown of major cost components for establishing a medium-scale feed mill with 5-10 tons per hour capacity.

| Investment Component | Estimated Cost Range (NGN) | Percentage of Total Investment | Notes |

| Land Acquisition (1-2 acres) | 25,000,000 – 60,000,000 | 15-20% | Varies significantly by location within Lagos |

| Building Construction | 40,000,000 – 80,000,000 | 20-25% | Including production area, storage, and office space |

| Core Processing Equipment | 50,000,000 – 120,000,000 | 30-40% | Feed pellet machines, hammer mills, mixers, etc. |

| Material Handling Systems | 15,000,000 – 35,000,000 | 10-15% | Conveyors, elevators, silos, bagging systems |

| Utilities Setup | 8,000,000 – 20,000,000 | 5-8% | Power generators, water systems, electrical installations |

| Quality Control Laboratory | 5,000,000 – 15,000,000 | 3-5% | Testing equipment and facilities |

| Vehicles & Logistics | 10,000,000 – 25,000,000 | 5-8% | Delivery trucks, forklifts, loaders |

| Permits & Licensing | 2,000,000 – 5,000,000 | 1-2% | Regulatory approvals and certifications |

| Initial Working Capital | 15,000,000 – 40,000,000 | 10-15% | Raw materials, staff salaries, operations for 3-6 months |

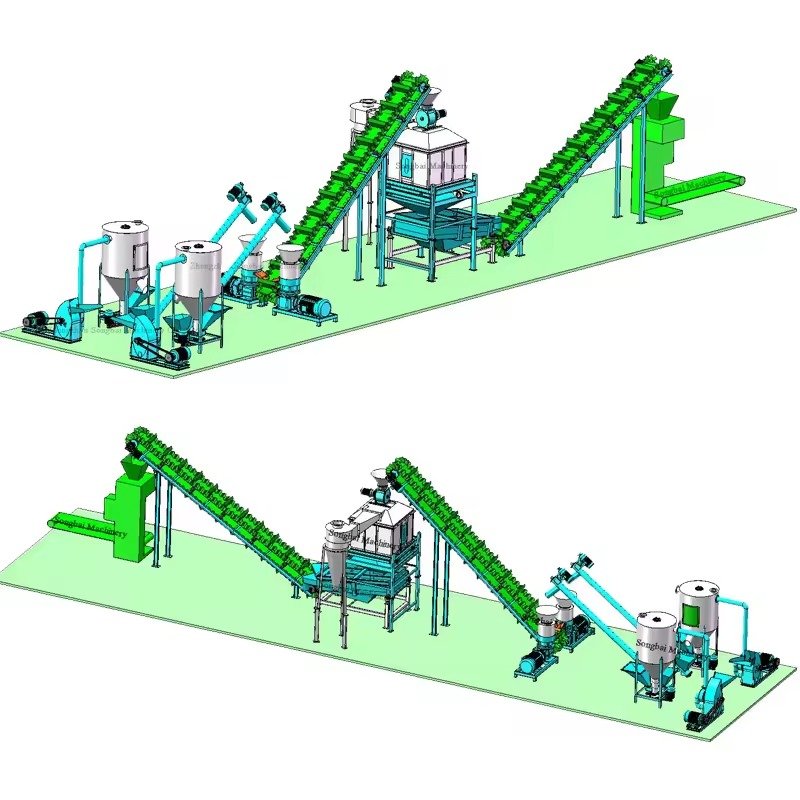

MAIKONG feed pellet machine installation in a Lagos facility

Need Personalized Equipment Cost Estimates?

MAIKONG offers detailed quotations for feed mill equipment tailored to your production requirements and budget. Our experts can help optimize your investment for maximum efficiency and return.

Essential Equipment for Your Lagos Feed Mill

The heart of any successful feed mill operation is its equipment. Selecting the right machinery based on your production goals, feed types, and budget is crucial for operational efficiency and product quality. MAIKONG offers a comprehensive range of feed processing equipment designed specifically for Nigerian operating conditions.

Core Processing Equipment Categories

Grinding Equipment

Hammer mills and crushers that reduce raw materials to optimal particle sizes for different animal feed requirements. Available in capacities from 1-20 tons per hour.

High ROI

Mixing Systems

Horizontal and vertical mixers ensuring uniform distribution of ingredients, vitamins, and additives. Precision mixing technology for consistent feed quality.

Quality Control

Pelleting Systems

Feed pellet machines that compress mixed ingredients into digestible, uniform pellets. Available in various capacities with customizable die configurations.

Value Addition

Material Handling

Conveyors, elevators, and pneumatic systems for efficient material movement throughout the production process, minimizing manual handling and contamination risks.

Cooling & Drying

Counter-flow coolers and dryers that reduce moisture content and temperature of processed feed, ensuring proper storage stability and shelf life.

Packaging Solutions

Weighing, bagging, and sealing systems that ensure accurate packaging weights and proper product presentation for market distribution.

Explore MAIKONG’s Feed Processing Equipment

From individual machines to complete production lines, MAIKONG offers tailored solutions for every feed production need. Our equipment is designed for Nigerian operating conditions with easy maintenance and reliable performance.

Ongoing Operational Costs for Lagos Feed Mills

Beyond the initial investment, understanding the recurring operational costs is essential for sustainable feed mill management. These expenses significantly impact your pricing strategy and profit margins.

Daily operations in a Lagos feed production facility

Monthly Operational Expense Breakdown

| Expense Category | Estimated Monthly Cost (NGN) | Percentage of Operating Costs | Cost Reduction Strategies |

| Raw Materials | 25,000,000 – 60,000,000 | 60-70% | Bulk purchasing, direct sourcing from farmers, seasonal stockpiling |

| Electricity/Power | 2,000,000 – 5,000,000 | 8-12% | Energy-efficient equipment, solar supplements, optimized production scheduling |

| Labor | 1,500,000 – 4,000,000 | 5-10% | Automation, staff training for multi-tasking, productivity incentives |

| Maintenance | 800,000 – 2,000,000 | 3-5% | Preventive maintenance schedules, operator training, quality spare parts |

| Transportation/Logistics | 1,000,000 – 3,000,000 | 4-8% | Route optimization, vehicle maintenance, full-load policies |

| Packaging Materials | 800,000 – 2,500,000 | 3-6% | Bulk purchasing, supplier negotiations, standardized packaging |

| Administrative Expenses | 500,000 – 1,500,000 | 2-4% | Digital systems, outsourcing non-core functions, shared services |

| Quality Control | 300,000 – 1,000,000 | 1-3% | In-house testing capabilities, staff training, preventive measures |

“Investing in quality equipment initially can significantly reduce long-term operational costs through improved energy efficiency, reduced maintenance needs, and higher production yields.”

Efficiency Optimization Tips

- Implement preventive maintenance schedules to avoid costly breakdowns

- Train operators on optimal equipment usage to maximize efficiency

- Monitor energy consumption and identify optimization opportunities

- Develop relationships with reliable raw material suppliers

- Consider automation for repetitive, labor-intensive processes

MAIKONG Technical Support

Our dedicated technical team provides ongoing support to optimize your feed mill operations. From equipment maintenance to process optimization, we’re committed to maximizing your operational efficiency.

Contact our technical support team via WhatsApp for immediate assistance:

Return on Investment Analysis for Lagos Feed Mill Operations

Understanding the potential return on investment is crucial when planning a feed mill venture. Below we analyze typical ROI scenarios based on different production capacities and market conditions in Lagos.

Financial planning for feed mill investment

ROI Projections by Production Scale

Small-Scale Operation

Production Capacity: 1-3 tons/hour

Initial Investment: ₦70-150 million

Annual Revenue Potential: ₦120-250 million

Estimated Payback Period: 2.5-3.5 years

Profit Margin: 15-20%

Target Market: Local farms, small-scale poultry operations

Medium-Scale Operation

Production Capacity: 5-10 tons/hour

Initial Investment: ₦180-350 million

Annual Revenue Potential: ₦350-700 million

Estimated Payback Period: 2-3 years

Profit Margin: 18-25%

Target Market: Regional distributors, medium-sized farms

Large-Scale Operation

Production Capacity: 15+ tons/hour

Initial Investment: ₦500 million – 1 billion+

Annual Revenue Potential: ₦1-2 billion+

Estimated Payback Period: 1.5-2.5 years

Profit Margin: 20-30%

Target Market: National distribution, export markets, large integrators

Factors Affecting ROI Performance

Positive ROI Factors

- Equipment efficiency and reliability

- Product diversification (poultry, livestock, aqua feeds)

- Value-added services (nutritional consulting)

- Strategic location near raw materials or markets

- Quality control systems ensuring premium products

- Energy-efficient operations reducing costs

ROI Risk Factors

- Raw material price volatility

- Equipment downtime and maintenance issues

- Market competition and price pressures

- Regulatory changes affecting operations

- Energy supply inconsistencies

- Currency fluctuations for imported components

MAIKONG Financing Options

MAIKONG offers flexible payment terms and financing options for qualified businesses looking to establish or upgrade feed mill operations in Nigeria. Our team can help structure equipment purchases to align with your cash flow projections and ROI targets.

Contact our sales team to discuss financing options:

MAIKONG: Your Partner for Feed Mill Success in Lagos

With over 20 years of experience in feed processing equipment manufacturing, MAIKONG offers comprehensive solutions for establishing efficient and profitable feed mill operations in Lagos and throughout Nigeria.

MAIKONG complete feed production line installation

Our Specialized Feed Processing Equipment

Poultry Feed Solutions

Specialized equipment for producing high-quality poultry feeds with precise nutritional profiles for layers, broilers, and breeders.

Aqua Feed Systems

Advanced extruders and pelletizers designed specifically for floating and sinking fish feeds with optimal water stability.

Livestock Feed Lines

Complete production systems for cattle, sheep, goat, and pig feeds with customizable configurations based on nutritional requirements.

Why Choose MAIKONG for Your Lagos Feed Mill Project

MAIKONG Advantages

- Over 20 years of specialized experience in feed processing equipment

- Equipment designed specifically for Nigerian operating conditions

- Comprehensive technical support via WhatsApp and on-site visits

- Customization options for specific production requirements

- Reliable spare parts availability and maintenance support

- Energy-efficient designs reducing operational costs

- Scalable solutions allowing for future expansion

- Local presence with dedicated Nigerian support team

What production capacity is right for my Lagos feed mill?

The ideal production capacity depends on your target market, available investment, and growth plans. For new entrants, starting with 2-5 tons/hour capacity allows for manageable initial investment while serving a substantial customer base. MAIKONG’s technical team can conduct a detailed analysis of your specific requirements to recommend the optimal capacity configuration.

How long does it take to set up a complete feed mill in Lagos?

The timeline varies based on scale and complexity, but typically ranges from 3-6 months for small to medium operations and 6-12 months for larger facilities. This includes building construction, equipment installation, testing, and commissioning. MAIKONG provides project management support to ensure efficient implementation according to your timeline requirements.

What ongoing support does MAIKONG provide after installation?

MAIKONG offers comprehensive post-installation support including operator training, preventive maintenance programs, spare parts supply, troubleshooting assistance, and process optimization consulting. Our technical team is available via WhatsApp for immediate support, and we conduct regular follow-up visits to ensure optimal equipment performance.

Taking the Next Step in Your Feed Mill Journey

Establishing a commercial feed mill in Lagos represents a significant but potentially rewarding investment in Nigeria’s growing agricultural sector. With careful planning, quality equipment selection, and strategic operational management, feed production facilities can achieve strong returns while contributing to the country’s food security and agricultural development.

MAIKONG is committed to supporting your feed mill venture from initial planning through equipment selection, installation, and ongoing operations. Our team of experts understands the unique challenges and opportunities in the Nigerian market and can provide tailored solutions to ensure your success.

Ready to Start Your Feed Mill Project?

Contact MAIKONG today for a personalized consultation and detailed quotation for your feed mill equipment needs. Our experts will help you design a solution that maximizes efficiency and return on investment.

Visit our website for more information: https://pelletmachine.ng/

Contact us online by Whatsapp: