South Africa Top pellet machine, animal feed pellet machine Manufacturer

Feed Pellet Machine: The Complete Guide from South Africa’s Leading Manufacturer

January 22, 2026

Why Feed Pellets Matter for South African Livestock Production

Converting raw agricultural materials into pellets offers significant advantages for modern livestock operations. Our feed pellet machines help South African farmers maximize their feeding efficiency and profitability.

Key Benefits of Pelleted Feed

- Improved feed conversion rates and faster weight gain

- Reduced feed waste and selective feeding behavior

- Better digestibility and nutrient absorption

- Easier storage, transportation, and handling

- Extended shelf life with reduced risk of contamination

- Ability to incorporate diverse ingredients into uniform pellets

- Customizable formulations for different livestock needs

The Economics of Feed Pelleting

For South African livestock producers, investing in a feed pellet machine delivers compelling financial returns. By producing your own pelleted feed, you can:

- Reduce feed costs by up to 30% compared to commercial feeds

- Utilize locally available raw materials and by-products

- Customize nutritional content for optimal animal performance

- Minimize storage space requirements by 20-25%

- Create additional revenue by producing feed for neighboring farms

Ready to Transform Your Feed Production?

Discuss your specific requirements with our technical team and discover the ideal feed pellet solution for your operation.

Essential Components of a Quality Feed Pellet Machine

Understanding the key components of a feed pellet machine helps you make an informed purchasing decision. MAIKONG’s engineering excellence ensures each component meets the highest standards for durability and performance.

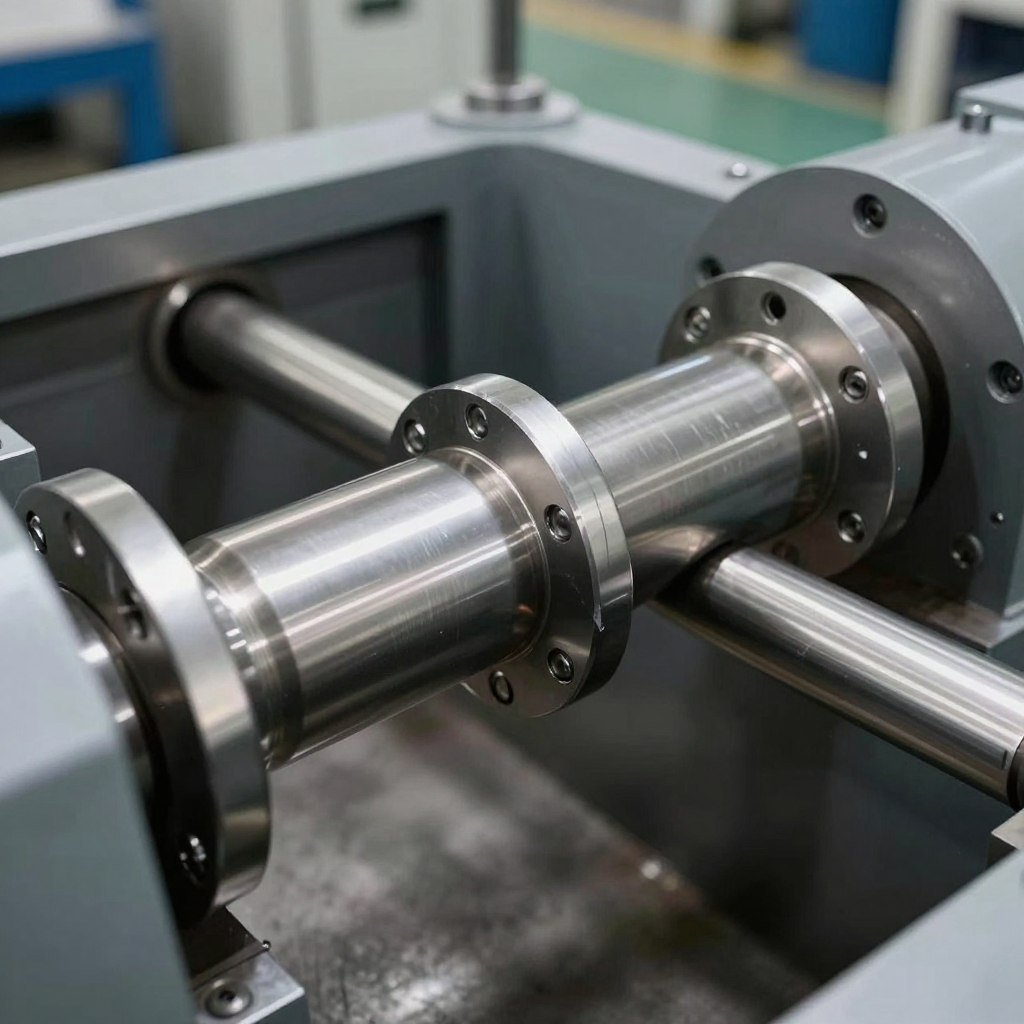

Die and Roller Assembly

The heart of any feed pellet machine, our precision-engineered dies and rollers are manufactured from premium alloy steel for extended service life. Available in multiple configurations to process various raw materials and produce pellets from 2-8mm in diameter.

Conditioning System

Our advanced conditioning chambers prepare raw materials with precise moisture and temperature control, significantly improving pellet quality and production efficiency. Proper conditioning reduces wear on dies while enhancing pellet durability.

Drive System

MAIKONG machines feature robust power transmission systems with options for both gear-driven and belt-driven configurations. Our motors range from 3kW for small operations to 30kW for industrial-scale production, all designed for reliability under continuous operation.

Feeding System

Precise material flow control ensures consistent pellet quality and prevents machine overloading. Our variable-speed feeding systems adapt to different material densities and production requirements.

Cutting Mechanism

Adjustable cutting blades ensure uniform pellet length regardless of diameter or production speed. Our precision-engineered cutting systems minimize fines and maximize finished product quality.

Control Systems

From basic manual controls to advanced PLC systems with digital monitoring, MAIKONG offers control solutions for every operation scale. Our user-friendly interfaces provide essential production data while protecting equipment through automated safety features.

Expert Technical Support Available

Have questions about feed pellet machine components? Our engineering team is ready to provide detailed technical information.

MAIKONG Feed Pellet Machine Models for South African Agriculture

MAIKONG offers a comprehensive range of feed pellet machines designed to meet diverse production requirements across South Africa’s agricultural sector. From small-scale farm operations to commercial feed mills, we provide solutions tailored to your specific needs.

| Model | Capacity (kg/h) | Power (kW) | Pellet Size (mm) | Ideal Application |

| MZLH-120 | 50-80 | 3 | 2-8 | Small farms, hobby operations |

| MZLH-150 | 100-150 | 4 | 2-8 | Small to medium farms |

| MZLH-200 | 150-200 | 7.5 | 2-8 | Medium-sized livestock operations |

| MZLH-250 | 200-300 | 11 | 2-8 | Commercial farms |

| MZLH-300 | 300-500 | 15 | 2-8 | Large farms, small feed mills |

| MZLH-400 | 500-700 | 22 | 2-10 | Commercial feed production |

| MZLH-500 | 800-1000 | 30 | 2-12 | Industrial feed mills |

Specialized Feed Pellet Machines by Livestock Type

Poultry Feed Pellet Machines

Our poultry feed pellet machines are optimized for producing the smaller diameter pellets and crumbles required for chicken, duck, and other poultry operations. These machines feature:

- Specialized dies for 2-4mm pellet production

- Precise control systems for consistent quality

- Optional crumbling attachments for starter feeds

- High-efficiency motors for reduced operating costs

Cattle and Ruminant Feed Pellet Machines

For cattle, sheep, and goat operations, our ruminant feed pellet machines handle fibrous materials efficiently while producing durable pellets that maintain their integrity during storage and feeding. Key features include:

- Heavy-duty construction for processing fibrous materials

- Specialized conditioning systems for improved digestibility

- Dies optimized for 6-12mm pellet production

- Enhanced power transmission for consistent operation

Find Your Ideal Feed Pellet Machine

Tell us about your operation, and our experts will recommend the perfect machine for your specific requirements.

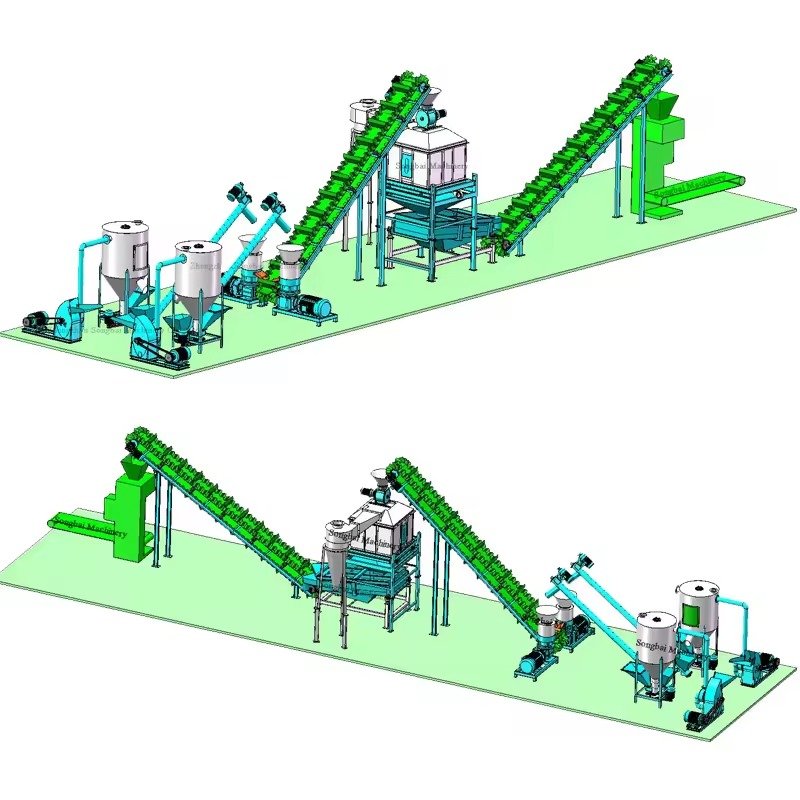

Complete Feed Pellet Production Lines

Beyond individual machines, MAIKONG designs and manufactures complete feed production lines that transform raw materials into finished, bagged feed pellets. Our turnkey solutions integrate seamlessly to maximize efficiency and product quality.

Essential Components in a Complete Feed Production Line

Raw Material Processing

Our hammer mills and grinders reduce raw materials to optimal particle sizes for pelleting. Available in capacities from 500kg to 5 tons per hour to match your production requirements.

Mixing Systems

Horizontal paddle mixers ensure homogeneous blending of ingredients, additives, and liquids. Our mixing systems achieve complete uniformity in 3-5 minutes, maximizing nutritional consistency.

Cooling and Drying

Counter-flow coolers reduce pellet temperature and moisture content to optimal levels for storage and handling. Our cooling systems preserve pellet quality while maximizing production efficiency.

Screening and Grading

Vibrating screens remove fines and ensure uniform product quality. Our screening systems maximize finished product yield while maintaining strict quality standards.

Packaging Solutions

Automated weighing and bagging systems ensure accurate packaging for retail or bulk distribution. Our packaging solutions handle bags from 5kg to 50kg with precision and efficiency.

Control Systems

Integrated PLC controls manage the entire production process from a single interface. Our control systems optimize efficiency while providing comprehensive production data.

What capacity feed production line is right for my operation?

The ideal capacity depends on your daily feed requirements, available space, and budget. As a general guideline:

- Small farms (50-100 animals): 100-200kg/hour

- Medium operations (100-500 animals): 200-500kg/hour

- Large farms (500+ animals): 500kg-1ton/hour

- Commercial feed production: 1-5 tons/hour

Our technical team can provide a detailed assessment based on your specific needs.

What space requirements should I consider for a complete production line?

Space requirements vary based on capacity and configuration. As a general guideline:

- Small systems (100-200kg/hour): 50-100m²

- Medium systems (200-500kg/hour): 100-200m²

- Large systems (500kg-1ton/hour): 200-400m²

- Industrial systems (1ton+/hour): 400m²+

Our design team can create custom layouts to maximize efficiency in your available space.

Design Your Custom Feed Production Line

From individual machines to complete turnkey solutions, MAIKONG has the expertise to design and implement the perfect system for your needs.

Customized Feed Pellet Solutions for South African Requirements

At MAIKONG, we understand that every feed production operation has unique requirements. Our engineering team works closely with clients to develop customized solutions that address specific challenges and opportunities in the South African market.

Customization Options

- Die and roller configurations for specific raw materials

- Power supply adaptations (380V, 220V, diesel, PTO)

- Capacity modifications to match production requirements

- Integration with existing equipment and facilities

- Special materials for food-grade applications

- Custom control systems and automation levels

- Specialized conditioning for difficult materials

Our Customization Process

- Detailed consultation to understand your specific requirements

- Technical assessment of raw materials and production goals

- Custom engineering and design proposal

- Manufacturing with rigorous quality control

- Factory testing to verify performance specifications

- Professional installation and commissioning

- Operator training and ongoing technical support

“MAIKONG worked closely with us to design a feed pellet system that perfectly matched our unique requirements for processing lucerne. Their customized solution has significantly improved our production efficiency and pellet quality.”

Discuss Your Custom Requirements

Our engineering team is ready to develop a tailored solution for your specific feed production needs.

Comprehensive Support for Your Feed Pellet Operation

MAIKONG’s commitment to your success extends beyond equipment sales. We provide comprehensive support services to ensure your feed pellet machine operates at peak efficiency throughout its service life.

Installation & Commissioning

Our experienced technicians ensure proper installation and startup of your equipment. We provide comprehensive commissioning services to verify all systems operate according to specifications.

Operator Training

Comprehensive training ensures your team can operate and maintain equipment safely and efficiently. We provide both theoretical and hands-on instruction tailored to your specific equipment configuration.

Maintenance Support

Regular maintenance maximizes equipment life and performance. Our service programs include scheduled maintenance visits, wear part replacement, and system optimization to minimize downtime.

Real-Time Technical Support

MAIKONG provides immediate technical assistance via WhatsApp. Our support team can troubleshoot issues, provide operating guidance, and coordinate spare parts delivery to minimize downtime.

For technical support, contact: +86 135 1090 7401

Spare Parts Program

MAIKONG maintains comprehensive spare parts inventory for all equipment models. Our spare parts program ensures:

- Genuine OEM parts manufactured to original specifications

- Fast delivery throughout South Africa

- Technical assistance for installation

- Customized wear part packages for your specific operation

Process Optimization

Our technical team helps optimize your feed production process for maximum efficiency and product quality. Services include:

- Formula development for specific livestock requirements

- Process parameter optimization for different raw materials

- Energy efficiency assessments and improvements

- Production capacity enhancement recommendations

Experience MAIKONG’s Superior Support

Join the growing community of satisfied MAIKONG customers throughout South Africa who rely on our expertise and support.

Partner with South Africa’s Leading Feed Pellet Machine Manufacturer

With over 20 years of manufacturing experience, MAIKONG has established itself as South Africa’s premier provider of feed pellet machines and complete production solutions. Our commitment to quality, innovation, and customer support has made us the trusted partner for agricultural operations throughout the region.

Why Choose MAIKONG

- 20+ years of specialized manufacturing experience

- Comprehensive product range from small farm units to industrial systems

- Custom engineering capabilities for unique requirements

- Robust after-sales support and technical assistance

- Extensive spare parts inventory for all models

- Proven performance in South African conditions

Get Started Today

Ready to transform your feed production operation? Contact MAIKONG today to discuss your requirements and discover the perfect feed pellet machine solution for your needs.

Email: Lucy@pelletmachine.co.za

Website: https://pelletmachine.co.za/

Request Your Custom Quote Today

Tell us about your feed production requirements, and we’ll provide a detailed proposal tailored to your specific needs.

Contact us online by Whatsapp: