South Africa Top pellet machine, animal feed pellet machine Manufacturer

Premium Alfalfa Pellet Machine for South African Businesses: MAIKONG’s Complete Guide

January 26, 2026

What is an Alfalfa Pellet Machine and How Does It Work?

An alfalfa pellet machine is specialized equipment designed to compress dried alfalfa (also known as lucerne in South Africa) into dense, uniform pellets. These machines transform loose, bulky alfalfa into compact, easy-to-handle pellets that offer improved storage, transportation, and feeding efficiency.

Working Principle of Alfalfa Pellet Mills

The pelleting process involves several key steps:

- Raw alfalfa is first dried to achieve optimal moisture content (approximately 15%)

- The dried material is ground into a fine powder using a hammer mill

- The powder is fed into the pellet machine’s conditioning chamber

- Rollers compress the material against a die (flat or ring type)

- The compression generates heat and pressure that binds the material

- Formed pellets are cut to desired length and discharged

- Fresh pellets are cooled to stabilize their structure

MAIKONG offers two main types of alfalfa pellet machines:

Flat Die Pellet Mills

- Ideal for small to medium production

- Lower initial investment

- Easier maintenance and die replacement

- Production capacity: 50-500 kg/hour

- Perfect for farm-scale operations

Ring Die Pellet Mills

- Suitable for medium to large production

- Higher durability for continuous operation

- Enhanced production efficiency

- Production capacity: 500-5000 kg/hour

- Ideal for commercial feed production

Key Benefits of MAIKONG Alfalfa Pellet Machines for South African Businesses

Advantages of Alfalfa Pelleting

- Reduces storage space by 80% compared to loose alfalfa

- Extends shelf life to 1-2 years with proper storage

- Minimizes transportation costs due to increased density

- Improves feed efficiency and reduces waste

- Creates value-added products from raw agricultural materials

- Enables precise nutritional formulation for livestock

- Reduces dust and improves handling safety

Challenges Without Proper Equipment

- Inconsistent pellet quality affects animal nutrition

- Excessive energy consumption with inefficient machines

- Frequent breakdowns lead to production delays

- Poor after-sales support impacts business continuity

- Inadequate customization for local materials

- High maintenance costs from inferior components

- Limited production capacity restricts business growth

Why South African Businesses Choose MAIKONG Alfalfa Pellet Machines

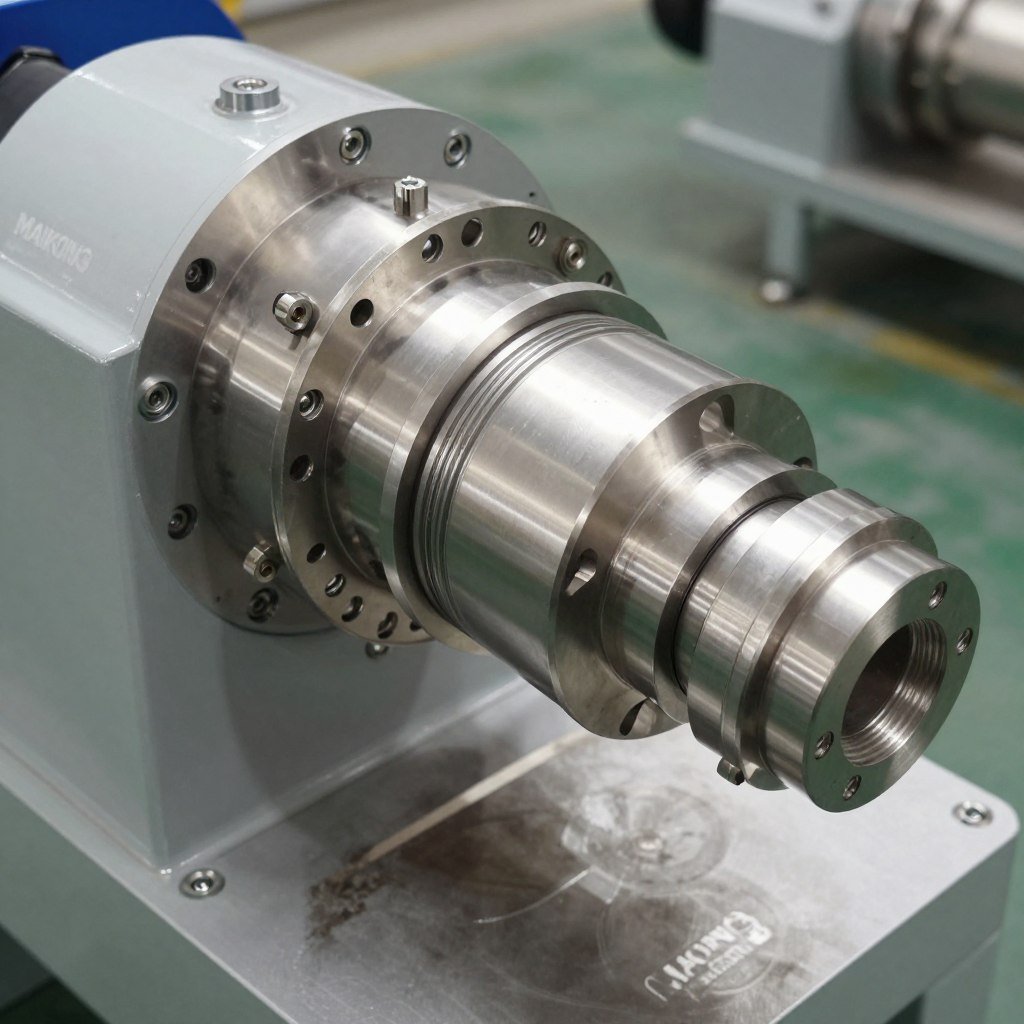

Durability & Reliability

Our machines feature hardened steel components and robust construction designed for the demanding conditions of continuous operation in South African agricultural environments.

Energy Efficiency

MAIKONG machines are engineered to minimize power consumption while maximizing output, reducing your operational costs and improving profitability.

Local Technical Support

We provide dedicated WhatsApp technical support and on-site assistance for South African customers, ensuring minimal downtime and maximum productivity.

Ready to Improve Your Alfalfa Processing Efficiency?

Contact our South African specialists today for a personalized consultation on the best alfalfa pellet machine for your specific needs.

MAIKONG’s 20+ Years of Expertise in Pellet Machinery

With over two decades of specialized experience in designing and manufacturing pellet machinery, MAIKONG has established itself as a trusted partner for South African agricultural businesses. Our journey began with a focus on understanding the unique requirements of different materials and operating environments, leading to continuous innovation in our alfalfa pellet machine designs.

Our Commitment to South African Customers

- Local Market Understanding: We’ve studied South African alfalfa varieties and processing requirements to optimize our machines for local conditions.

- Continuous Innovation: Our R&D team constantly improves designs based on customer feedback and technological advancements.

- Quality Assurance: Every machine undergoes rigorous testing before shipping to ensure reliable performance in the field.

- Comprehensive Support: From installation to operation training and maintenance, we provide end-to-end assistance.

- Customization Capabilities: We adapt our machines to meet specific requirements of South African agricultural operations.

“MAIKONG’s alfalfa pellet machie has transformed our feed production efficiency. The local technical support has been exceptional, helping us optimize our operation for South African conditions.”

MAIKONG’s Comprehensive Alfalfa Pellet Machine Range

MAIKONG offers a comprehensive range of alfalfa pellet machines to suit operations of all sizes in South Africa. From small farm models to large industrial units, our equipment is designed to deliver optimal performance with South African alfalfa varieties.

Small-Scale Alfalfa Pellet Machines

| Model | Output (kg/h) | Power (kW) | Die Diameter (mm) | Pellet Size (mm) | Ideal For |

| MK-150B | 50-100 | 5.5 | 150 | 2-8 | Small farms, hobby operations |

| MK-200B | 80-120 | 7.5 | 200 | 2-10 | Medium farms, small businesses |

| MK-230B | 120-200 | 11 | 230 | 2-12 | Commercial farms, feed retailers |

Industrial Alfalfa Pellet Machines

| Model | Output (kg/h) | Power (kW) | Die Type | Pellet Size (mm) | Ideal For |

| MK-350R | 500-800 | 37 | Ring Die | 2-12 | Feed manufacturers, medium enterprises |

| MK-420R | 1000-1500 | 90 | Ring Die | 2-12 | Large feed mills, commercial production |

| MK-520R | 2000-3000 | 132 | Ring Die | 2-12 | Industrial feed producers, exporters |

Note: All MAIKONG alfalfa pellet machines can be customized to meet specific South African requirements, including power supply configurations, production capacity adjustments, and integration with existing equipment.

Need Help Selecting the Right Model?

Our South African specialists can help you choose the perfect alfalfa pellet machine based on your production requirements, budget, and growth plans.

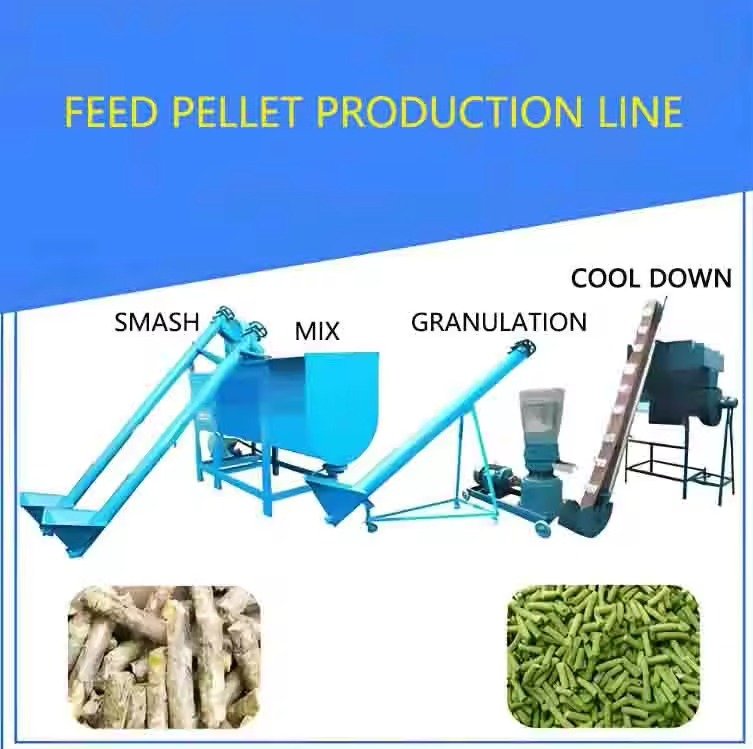

Complete Alfalfa Pellet Production Lines

Beyond individual machines, MAIKONG specializes in designing and installing complete alfalfa pellet production lines tailored to South African requirements. Our turnkey solutions include all necessary equipment from raw material handling to finished product packaging.

Components of a Complete Alfalfa Pellet Production Line

Pre-Processing Equipment

- Bale breakers for handling compressed alfalfa

- Hammer mills for grinding to optimal particle size

- Dryers for achieving ideal moisture content

- Mixers for blending additives if required

Core Pelleting System

- Conditioning chamber for optimal material preparation

- Main pellet mill (flat die or ring die)

- Advanced control systems for process management

- Safety systems for operator protection

Post-Processing Equipment

- Coolers for stabilizing fresh pellets

- Screeners for removing fines

- Packaging systems for bagging finished product

- Storage solutions for finished pellets

Production Line Capacity Options

| Production Scale | Capacity (tons/hour) | Power Requirement (kW) | Space Required (m²) | Ideal For |

| Small | 0.5-1 | 30-50 | 100-200 | Small agricultural cooperatives, medium farms |

| Medium | 1-3 | 50-150 | 200-500 | Commercial feed producers, large farms |

| Large | 3-10 | 150-500 | 500-1500 | Industrial feed manufacturers, exporters |

MAIKONG Advantage: Our engineering team provides complete project planning, installation supervision, and commissioning services for all production lines. We ensure your alfalfa pellet operation starts smoothly and operates efficiently from day one.

Applications of Alfalfa Pellets in South Africa

Understanding the end-use of alfalfa pellets helps in selecting the right alfalfa pellet machine for your specific needs. In South Africa, alfalfa pellets serve multiple valuable purposes:

Animal Feed Applications

- Dairy Cattle: High-protein supplement that improves milk production and quality

- Beef Cattle: Nutrient-dense feed that promotes healthy weight gain

- Horses: Premium forage with balanced nutrition and reduced dust

- Sheep and Goats: Excellent protein source for wool and meat production

- Poultry: Nutritional supplement that enhances egg quality

- Rabbits: Complete feed solution with optimal fiber content

Alternative Applications

- Biofuel Production: Renewable energy source with consistent burning properties

- Organic Fertilizer: Slow-release nutrient source for crop production

- Export Markets: Value-added agricultural product for international trade

- Pet Food Industry: Ingredient in premium small animal feeds

- Mushroom Cultivation: Substrate component for certain varieties

- Soil Amendment: Improves soil structure and fertility

Benefits of Alfalfa Pellets vs. Raw Alfalfa

| Characteristic | Raw Alfalfa | Alfalfa Pellets | Advantage |

| Storage Space | High (bulky) | Low (compact) | 80% space reduction |

| Shelf Life | 3-6 months | 1-2 years | Extended storage potential |

| Nutrient Loss | High | Minimal | Better nutritional value |

| Feeding Waste | 20-30% | 5-10% | Reduced feed costs |

| Transportation Cost | High | Low | Improved logistics |

Customization Options for South African Requirements

MAIKONG understands that South African agricultural operations have unique requirements. Our alfalfa pellet machines can be customized in numerous ways to meet your specific needs:

Material Adaptations

- Die configurations optimized for South African alfalfa varieties

- Roller designs adjusted for local material characteristics

- Feed system modifications for different input materials

- Multi-material capability for processing mixed feeds

Technical Customizations

- Power systems adapted to South African electrical standards

- Production capacity adjustments to match your requirements

- Control systems with local language interfaces

- Integration capabilities with existing equipment

Support Customizations

- Operator training programs in local languages

- Maintenance schedules adapted to local conditions

- Spare parts packages tailored to your operation

- Technical documentation customized for your team

Need a Customized Solution?

Contact our engineering team to discuss your specific requirements for an alfalfa pellet machine perfectly adapted to your South African operation.

Comprehensive Support for South African Customers

At MAIKONG, we believe that exceptional support is as important as high-quality equipment. Our comprehensive support services ensure that your alfalfa pellet machine operates at peak efficiency throughout its lifecycle.

Our Support Services Include:

Pre-Purchase Support

- Detailed technical consultations to determine your exact needs

- Production capacity planning and ROI calculations

- Site assessment and installation requirements analysis

- Custom solution development for unique applications

- Sample testing with your specific materials

Installation & Commissioning

- Professional installation supervision by experienced engineers

- Comprehensive commissioning and testing procedures

- Operator training programs with hands-on instruction

- Initial production optimization for maximum efficiency

- Quality control procedures implementation

Ongoing Technical Support

- Immediate WhatsApp technical assistance for troubleshooting

- Regular maintenance schedules and reminders

- Software updates and performance optimization

- Process improvement consultations

- Remote diagnostics capabilities

Parts & Maintenance

- Fast delivery of genuine spare parts to South Africa

- Preventive maintenance programs to minimize downtime

- Wear parts replacement guidance and training

- Equipment upgrade options as your business grows

- Extended warranty programs

MAIKONG WhatsApp Technical Support: Our dedicated technical team is available via WhatsApp to provide immediate assistance with any operational questions or issues. Simply add our technical support number: +86 135 1090 7401

Frequently Asked Questions About Alfalfa Pellet Machines

What is the ideal moisture content for alfalfa before pelleting?

The optimal moisture content for alfalfa before processing through an alfalfa pellet machine is between 12-15%. Too much moisture can cause clogging and poor pellet formation, while too little moisture can result in excessive wear on machine components and poor pellet binding. MAIKONG machines include moisture monitoring systems to help maintain optimal conditions.

How much power is required to run an alfalfa pellet machine?

Power requirements vary based on the machine’s capacity. Small farm models typically require 5.5-15kW, medium-sized commercial units need 22-90kW, and large industrial machines can require 132kW or more. MAIKONG offers solutions compatible with South African power infrastructure, including options for areas with unstable power supply.

What is the difference between flat die and ring die pellet machines?

Flat die machines have a horizontal rotating die with stationary rollers pressing material through it. They’re generally more suitable for smaller operations due to their lower cost and easier maintenance. Ring die machines have a vertical rotating die with rollers inside, offering higher production capacity and efficiency for commercial operations. MAIKONG offers both types to suit different production scales.

How long do the dies and rollers last before replacement?

Die and roller lifespan depends on several factors including material hardness, production volume, and maintenance practices. Typically, dies last for 1,000-1,500 production hours and rollers for 800-1,200 hours when processing alfalfa. MAIKONG uses premium hardened steel for extended component life and offers fast replacement part delivery to South Africa.

Can MAIKONG machines process other materials besides alfalfa?

Yes, MAIKONG alfalfa pellet machines are versatile and can process various materials including other forage grasses, straw, wood chips, and agricultural residues. Different die configurations may be required for optimal results with each material type. Our technical team can advise on the best setup for your specific material mix.

What maintenance is required for alfalfa pellet machines?

Regular maintenance includes daily cleaning, weekly lubrication checks, monthly bearing inspections, and periodic die and roller examination. MAIKONG provides detailed maintenance schedules, training, and support to ensure your machine remains in optimal condition. Our WhatsApp technical support can guide you through maintenance procedures step by step.

Why Choose MAIKONG for Your Alfalfa Pellet Machine Needs in South Africa

With over 20 years of specialized experience in pellet machinery manufacturing, MAIKONG has established itself as a trusted partner for South African agricultural businesses. Our commitment to quality, innovation, and customer support makes us the preferred choice for alfalfa pellet machines throughout South Africa.

The MAIKONG Advantage:

- South African Market Focus: Equipment designed specifically for local conditions and materials

- Comprehensive Product Range: Solutions for operations of all sizes, from small farms to industrial producers

- Superior Build Quality: Robust construction using premium components for exceptional durability

- Customization Capabilities: Machines tailored to your specific requirements and applications

- Dedicated Technical Support: Immediate assistance via WhatsApp and comprehensive after-sales service

- Complete Solution Provider: From individual machines to turnkey production lines

Ready to Transform Your Alfalfa Processing?

Contact MAIKONG today to discuss your alfalfa pellet machine requirements and discover how our solutions can enhance your agricultural operation.

Contact us online by Whatsapp: