South Africa Top pellet machine, animal feed pellet machine Manufacturer

Price Analysis: Factors Affecting Animal Feed Pellet Machine Costs in 2026

January 28, 2026

Market Overview: Animal Feed Pellet Machine Industry in 2026

The global market for feed processing equipment is projected to grow significantly by 2026, with South Africa representing a key growth region. Several factors are reshaping the animal feed pellet machine landscape, including technological advancements, sustainability requirements, and changing agricultural practices.

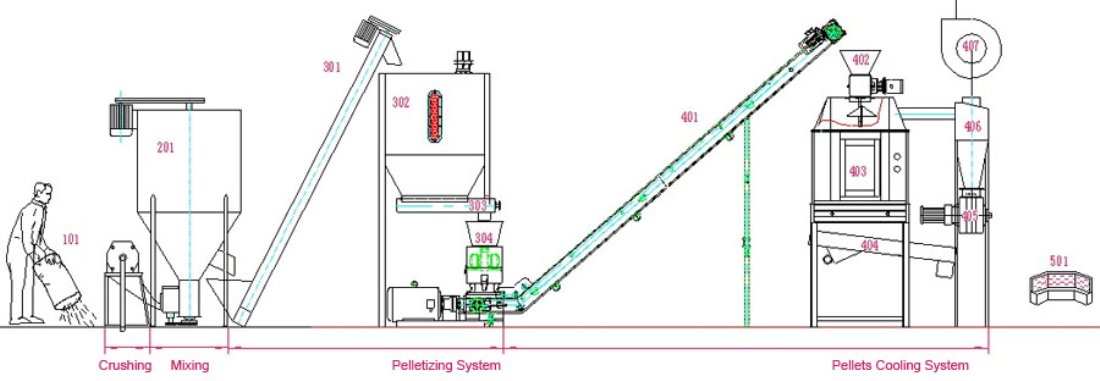

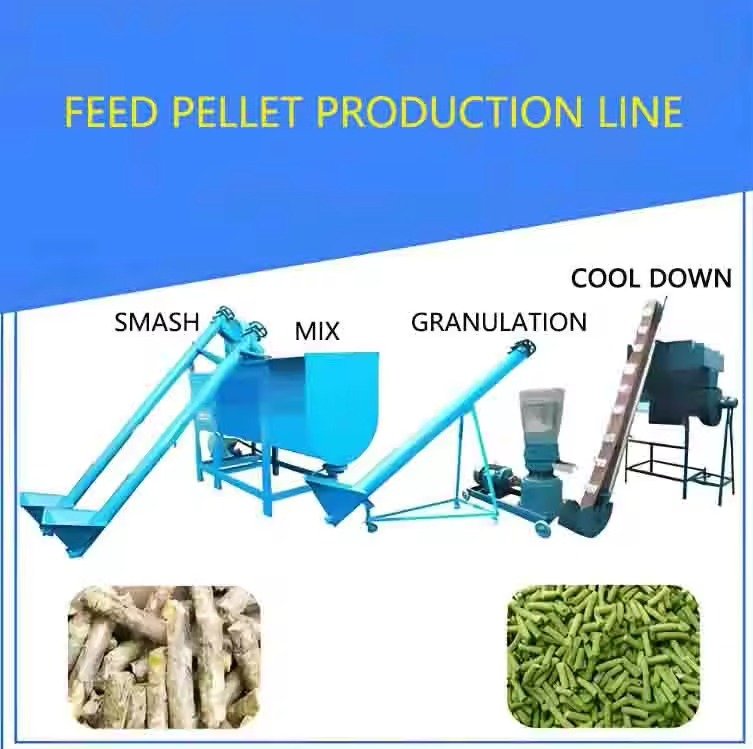

MAIKONG’s state-of-the-art production facility specializing in animal feed pellet machines

Current Market Trends

The feed pellet machine market is experiencing increased demand due to the growing livestock population and the shift toward efficient feeding systems. South African farmers are increasingly recognizing the economic benefits of pelleted feed, driving investment in quality production equipment.

Regional Demand Patterns

South Africa’s agricultural sector shows particular interest in medium to high-capacity feed pellet machines that balance production efficiency with energy consumption. The demand for customizable solutions that can process local raw materials has become a defining market characteristic.

Key Factors Influencing Animal Feed Pellet Machine Pricing

The cost of an animal feed pellet machine is determined by several interconnected factors. Understanding these elements helps buyers make more informed decisions and negotiate better terms with suppliers.

Production Capacity

The output capacity of a feed pellet machine significantly impacts its price. Machines range from small-scale units producing 50-100 kg/hour to industrial models capable of 1-3 tons per hour. Higher capacity machines require more robust components and advanced control systems, increasing costs proportionally.

Build Quality & Materials

Premium materials like stainless steel components and hardened dies significantly affect machine pricing. While higher-grade materials increase upfront costs, they typically offer better durability, reduced maintenance, and longer operational lifespans—factors that improve long-term ROI.

Technological Features

Modern feed pellet machines incorporate various technological advancements, from basic manual controls to sophisticated automated systems with digital monitoring. Advanced features like precision temperature control, automatic lubrication, and smart diagnostics add to the initial investment but enhance operational efficiency.

Energy Efficiency

With rising energy costs in South Africa, the power consumption of feed pellet machines has become a critical consideration. Energy-efficient models command premium prices but offer significant operational savings. The motor configuration and transmission system efficiency are key determinants of energy performance.

Customization Options

Tailored solutions designed for specific feed types or production requirements typically cost more than standard models. Customization may include specialized dies for particular pellet sizes, material-specific conditioning systems, or integration capabilities with existing production lines.

After-Sales Support

Comprehensive service packages, extended warranties, and readily available spare parts add value but also increase the total investment. For South African businesses, local technical support availability is particularly important given the specialized nature of these machines.

2026 Price Ranges for Different Animal Feed Pellet Machine Categories

The following analysis provides estimated price ranges for various categories of feed pellet machines available in the South African market in 2026. These figures represent base prices before customization or additional features.

| Machine Category | Production Capacity | Estimated Price Range (ZAR) | Suitable Application |

| Small-Scale Models | 50-200 kg/hour | R45,000 – R120,000 | Small farms, research facilities |

| Medium-Scale Models | 200-500 kg/hour | R120,000 – R350,000 | Medium-sized farms, small commercial operations |

| Commercial Models | 500-1000 kg/hour | R350,000 – R750,000 | Large farms, feed retailers |

| Industrial Models | 1-3 tons/hour | R750,000 – R1,800,000 | Feed mills, large commercial operations |

| Complete Production Lines | Varies (1-5+ tons/hour) | R1,800,000 – R5,000,000+ | Industrial feed manufacturers |

Need a Customized Price Quote?

Our team can provide detailed pricing information based on your specific production requirements and raw materials.

ROI Analysis for Animal Feed Pellet Machine Investments

Understanding the return on investment timeline is crucial when purchasing an animal feed pellet machine. The following analysis helps South African businesses evaluate the financial implications of their equipment investment.

Cost Savings Factors

- Reduced feed wastage (typically 15-25% improvement)

- Lower labor costs through automation

- Improved feed conversion ratios in livestock

- Ability to use lower-cost raw materials

- Reduced transportation and storage costs

- Potential for selling excess production

Typical Break-Even Timeline

Most South African businesses achieve ROI on their feed pellet machine investments within 12-36 months, depending on:

- Scale of operation and utilization rate

- Current feed costs and market prices

- Type and number of livestock

- Energy costs and operational efficiency

- Maintenance requirements and practices

“Our investment in a MAIKONG feed pellet machine paid for itself within 18 months through reduced feed costs and improved livestock performance. The ability to customize feed formulations for different growth stages has been particularly valuable.”

Customization Options and Their Impact on Animal Feed Pellet Machine Pricing

MAIKONG offers extensive customization options for our animal feed pellet machine range, allowing South African businesses to tailor equipment to their specific requirements. Understanding how these options affect pricing helps in making cost-effective decisions.

Die and Roller Configurations

Different die hole diameters (2-12mm) and roller hardness options allow for processing various feed materials. Custom die configurations typically add 5-15% to base machine costs but enable precise pellet size control for specific livestock requirements.

Power and Drive Systems

Options range from standard electric motors to diesel engines or PTO-driven systems for remote farm operations. Variable frequency drives add approximately 8-12% to costs but provide energy savings of up to 30% through optimized power consumption.

Control Systems

From basic manual controls to fully automated PLC systems with touch interfaces, control options significantly impact pricing. Advanced systems with remote monitoring capabilities typically increase base costs by 15-25% but reduce operator requirements and improve consistency.

Material Handling Components

Customized feeding systems, conditioners, and cooling equipment can be tailored to specific raw materials common in South African agriculture. These customizations generally add 10-20% to system costs but improve throughput and final product quality.

Integration Capabilities

Modifications for seamless integration with existing production equipment or facilities may add 5-15% to costs. However, these customizations maximize operational efficiency and minimize disruption during implementation.

Specialized Applications

Machines designed for specific feed types (e.g., lucerne, game feed, aquaculture feed) include material-specific optimizations. These specialized configurations typically command a 10-30% premium but deliver superior performance for their intended application.

Explore Customization Options

MAIKONG’s engineering team can develop tailored solutions for your specific feed production requirements.

The MAIKONG Advantage: Value-Added Features

With over 20 years of experience in designing and manufacturing feed processing equipment, MAIKONG offers several advantages that enhance the value proposition of our animal feed pellet machine range for South African businesses.

MAIKONG Value Proposition

- 20+ years of specialized manufacturing experience

- South Africa-specific designs optimized for local conditions

- Comprehensive technical support via WhatsApp and email

- Extended warranty options beyond industry standards

- Local spare parts availability reducing downtime

- Energy-efficient designs reducing operational costs

- Customization capabilities for specific feed requirements

- Ongoing R&D investment in pellet technology

Common Industry Challenges

- Limited technical support from overseas manufacturers

- Long lead times for spare parts and repairs

- Generic designs not optimized for South African materials

- High energy consumption increasing operational costs

- Restricted customization options

- Inconsistent pellet quality affecting livestock performance

- Limited durability in harsh operating environments

- Minimal after-sales service commitment

Technical Specifications of MAIKONG Animal Feed Pellet Machine Range

MAIKONG offers a comprehensive range of animal feed pellet machine models to meet diverse production requirements. Below are the technical specifications of our most popular models available to South African businesses.

| Model | Production Capacity | Power Requirement | Die Diameter | Dimensions (L×W×H) | Weight |

| MK-125 | 50-100 kg/hour | 3 kW | 125 mm | 0.66×0.32×0.68 m | 90 kg |

| MK-150 | 100-150 kg/hour | 4 kW | 150 mm | 0.78×0.32×0.75 m | 120 kg |

| MK-210 | 200-300 kg/hour | 7.5 kW | 210 mm | 0.97×0.43×0.95 m | 210 kg |

| MK-260 | 400-500 kg/hour | 15 kW | 260 mm | 1.25×0.52×1.1 m | 350 kg |

| MK-400 | 1000-1200 kg/hour | 30 kW | 400 mm | 1.67×0.63×1.55 m | 850 kg |

Available Pellet Sizes and Applications

Standard Pellet Diameters

- 2mm – Suitable for poultry starter feeds

- 3mm – Ideal for poultry grower feeds

- 4mm – Perfect for poultry finisher and small ruminant feeds

- 6mm – Recommended for cattle, sheep, and goat feeds

- 8mm – Optimal for cattle and horse feeds

- 10mm – Specialized for large livestock applications

Compatible Raw Materials

- Cereal grains (maize, wheat, barley)

- Protein sources (soybean meal, sunflower cake)

- Fibrous materials (lucerne, grass, straw)

- Agricultural by-products (bran, hulls)

- Mineral supplements and premixes

- Oil seeds and cakes

Frequently Asked Questions About Animal Feed Pellet Machine Pricing

What factors most significantly impact the price of an animal feed pellet machine?

The most significant price determinants are production capacity, build quality, and level of automation. Higher capacity machines with premium materials and advanced control systems command higher prices but typically offer better long-term value through improved durability and efficiency. For South African operations, we recommend balancing initial investment against projected throughput requirements and operational lifespan.

How do operating costs compare between different price tiers of feed pellet machines?

Higher-priced machines generally offer lower operating costs through better energy efficiency, reduced maintenance requirements, and longer component lifespans. Premium models typically consume 15-30% less energy per ton of feed produced compared to entry-level options. When calculating total cost of ownership, consider electricity costs, maintenance expenses, and expected die and roller replacement intervals.

What financing options are available for South African businesses purchasing feed pellet equipment?

MAIKONG works with several South African financial institutions offering agricultural equipment financing. Options include term loans, equipment leasing, and hire-purchase arrangements. Additionally, certain models may qualify for agricultural development incentives or sustainability grants. Our team can provide guidance on available financing options and connect you with appropriate financial partners.

How does customization affect the final price and delivery timeline?

Customization typically adds 5-30% to base machine costs depending on the extent of modifications required. Standard customizations like die size changes have minimal impact on delivery timelines (adding 1-2 weeks), while extensive modifications for specialized applications may extend delivery by 3-6 weeks. MAIKONG provides detailed customization quotes with transparent pricing and timeline implications.

What warranty and after-sales support is included in the purchase price?

All MAIKONG machines include a standard 12-month warranty covering manufacturing defects and component failures under normal operating conditions. Extended warranty options of 24 or 36 months are available at additional cost. Our after-sales support includes WhatsApp technical assistance, spare parts availability, and optional maintenance service contracts. For South African customers, we maintain a local inventory of critical spare parts to minimize potential downtime.

Contact MAIKONG for Personalized Animal Feed Pellet Machine Solutions

With over 20 years of experience in the feed processing equipment industry, MAIKONG is your trusted partner for high-quality animal feed pellet machine solutions in South Africa. Our team of experts is ready to assist you with personalized recommendations, detailed price quotes, and technical support.

Our Services

- Customized machine configurations

- Complete production line design

- Technical consultation and ROI analysis

- Installation and commissioning support

- Operator training programs

- Ongoing technical support

- Spare parts supply

- OEM manufacturing services

Contact Information

Our dedicated team is available to assist you with any inquiries about our animal feed pellet machine range and services.

For technical support, add our WhatsApp: +86 135 1090 7401

Email: Lucy@pelletmachine.co.za

Website: https://pelletmachine.co.za/

Ready to Optimize Your Feed Production?

Contact us today for a customized quote and expert consultation on the ideal feed pellet solution for your business.

Conclusion: Making an Informed Animal Feed Pellet Machine Investment

The market for animal feed pellet machine equipment continues to evolve, with pricing influenced by numerous factors including production capacity, build quality, technological features, and customization requirements. By understanding these price determinants, South African agricultural businesses can make more informed investment decisions that balance upfront costs with long-term operational benefits.

MAIKONG’s commitment to quality, customization, and local support makes us an ideal partner for South African businesses looking to optimize their feed production capabilities. With over two decades of industry experience and a deep understanding of the unique requirements of the South African agricultural sector, we provide solutions that deliver exceptional value and performance.

Contact our team today to discuss your specific requirements and discover how our animal feed pellet machine solutions can enhance your operation’s efficiency and profitability.

Contact us online by Whatsapp: