South Africa Top pellet machine, animal feed pellet machine Manufacturer

MAIKONG Factory Tour: How We Manufacture High-Quality Animal Feed Pellet Machine

January 31, 2026

MAIKONG: 20+ Years of Excellence in Animal Feed Pellet Machine Manufacturing

MAIKONG’s state-of-the-art manufacturing facility in South Africa

Since our founding, MAIKONG has been at the forefront of agricultural equipment innovation in South Africa. Our journey began with a simple mission: to provide African farmers and feed producers with reliable, efficient machinery that meets their unique needs. Today, we stand as a leading manufacturer of feed pellet machines with a reputation built on engineering excellence, durability, and outstanding customer support.

Our Manufacturing Philosophy

At MAIKONG, we believe that quality begins with understanding. Understanding the harsh conditions of African agriculture. Understanding the economic pressures facing our customers. Understanding the technical requirements for different feed materials. This knowledge forms the foundation of our manufacturing approach.

Local Expertise, Global Standards

Our team combines deep knowledge of South African agricultural requirements with international engineering standards. This unique perspective allows us to create animal feed processing equipment that performs exceptionally in local conditions while maintaining world-class quality.

Continuous Innovation

Our R&D department constantly works to improve our pellet machine designs, incorporating customer feedback and technological advancements. This commitment to innovation ensures our products remain at the cutting edge of feed processing technology.

Ready to explore our manufacturing capabilities?

Contact our technical team for a personalized consultation about your feed production needs.

Stage 1: Premium Raw Material Sourcing

Premium-grade materials awaiting processing in our quality control area

Every exceptional animal feed pellet machine begins with superior raw materials. At MAIKONG, we source only the highest quality steel, components, and materials to ensure durability and performance in demanding agricultural environments.

Material Selection Process

Our engineering team carefully selects materials based on specific requirements for each component. Critical wear parts such as dies and rollers are manufactured from specially hardened alloys that significantly extend service life when processing abrasive feed materials.

Our quality control team inspecting incoming materials

Quality Verification Standards

Before entering production, all materials undergo rigorous testing:

- Metallurgical composition analysis

- Hardness and tensile strength testing

- Dimensional accuracy verification

- Surface finish inspection

- Stress resistance evaluation

Only materials that pass our comprehensive quality checks move forward to the production floor, ensuring that every feed pellet machine we build starts with a solid foundation.

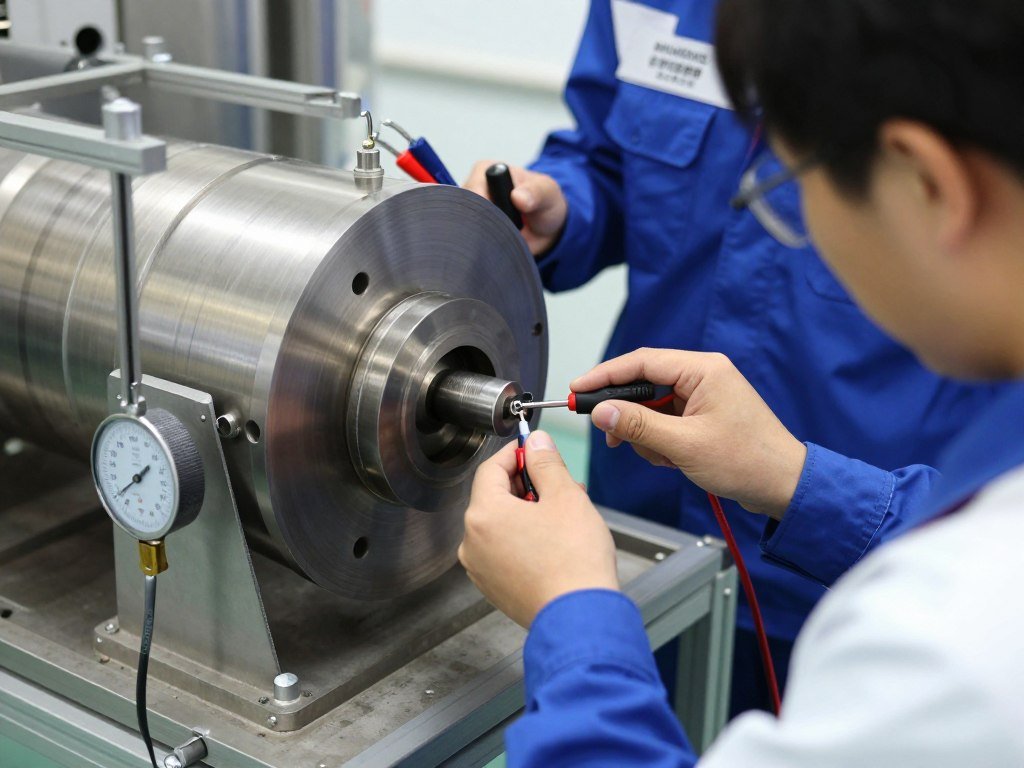

Stage 2: Precision Engineering and Component Manufacturing

CNC precision machining of critical pellet machine components

The heart of our manufacturing excellence lies in our precision engineering capabilities. MAIKONG utilizes advanced CNC machining centers and laser cutting technology to produce components with exacting tolerances.

Key Engineering Processes

CNC Machining

Our 5-axis CNC machines produce complex components with tolerances of ±0.01mm, ensuring perfect fit and function of critical parts like die plates and roller assemblies.

Laser Cutting

High-powered laser cutting systems create precise chassis components and structural elements, maintaining dimensional accuracy while eliminating material stress.

Die and Roller Production

Our specialized equipment produces hardened dies and rollers – the critical components that determine pellet quality and production efficiency.

Engineering Expertise in Action

What sets MAIKONG apart is our deep understanding of the mechanical principles behind efficient pellet formation. Our engineers continuously refine the critical geometries of dies and rollers to optimize for different feed materials and pellet sizes.

“The precision of the die and roller relationship is what determines both pellet quality and machine longevity. Our engineering team has perfected these critical components through years of research and field testing across various African agricultural conditions.”

Need custom die configurations for your specific feed materials?

Our engineering team can design custom solutions for your unique requirements.

Stage 3: Precision Assembly and Integration

Our skilled assembly technicians ensuring perfect component integration

Assembly is where individual components become a cohesive, functioning animal feed pellet machine. MAIKONG employs a systematic assembly process with multiple quality checkpoints to ensure every machine meets our exacting standards.

Our Assembly Process

Subassembly Integration

Before final assembly, key components like the pelletizing chamber, drive system, and control units undergo pre-assembly and testing. This modular approach ensures each system functions perfectly before integration into the complete machine.

Testing a pelletizing chamber subassembly before integration

Precision Alignment

The relationship between dies and rollers is critical for optimal pellet production. Our technicians use laser alignment tools to achieve perfect positioning, ensuring consistent pellet quality and minimizing wear on critical components.

- Chassis and frame assembly with jig verification

- Power transmission system integration

- Die and roller installation with precision alignment

- Control system integration and wiring

- Safety system installation and verification

Quality Verification During Assembly

Each assembly stage includes specific quality checks performed by both assembly technicians and dedicated quality control personnel. This dual-verification approach ensures no detail is overlooked.

Quality control verification during the assembly process

MAIKONG Assembly Advantage

Our assembly technicians average 8+ years of experience specifically with feed pellet machines. This specialized expertise allows them to identify and address potential issues before they affect machine performance.

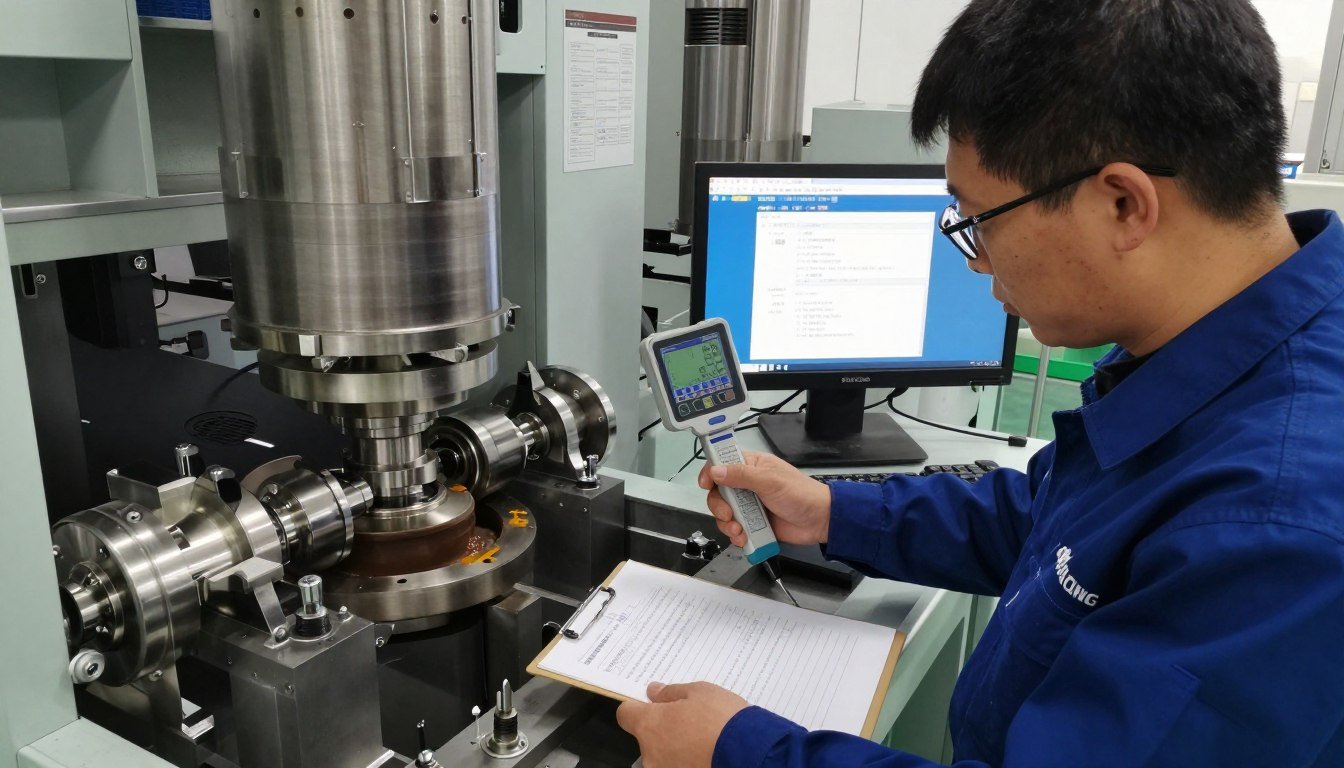

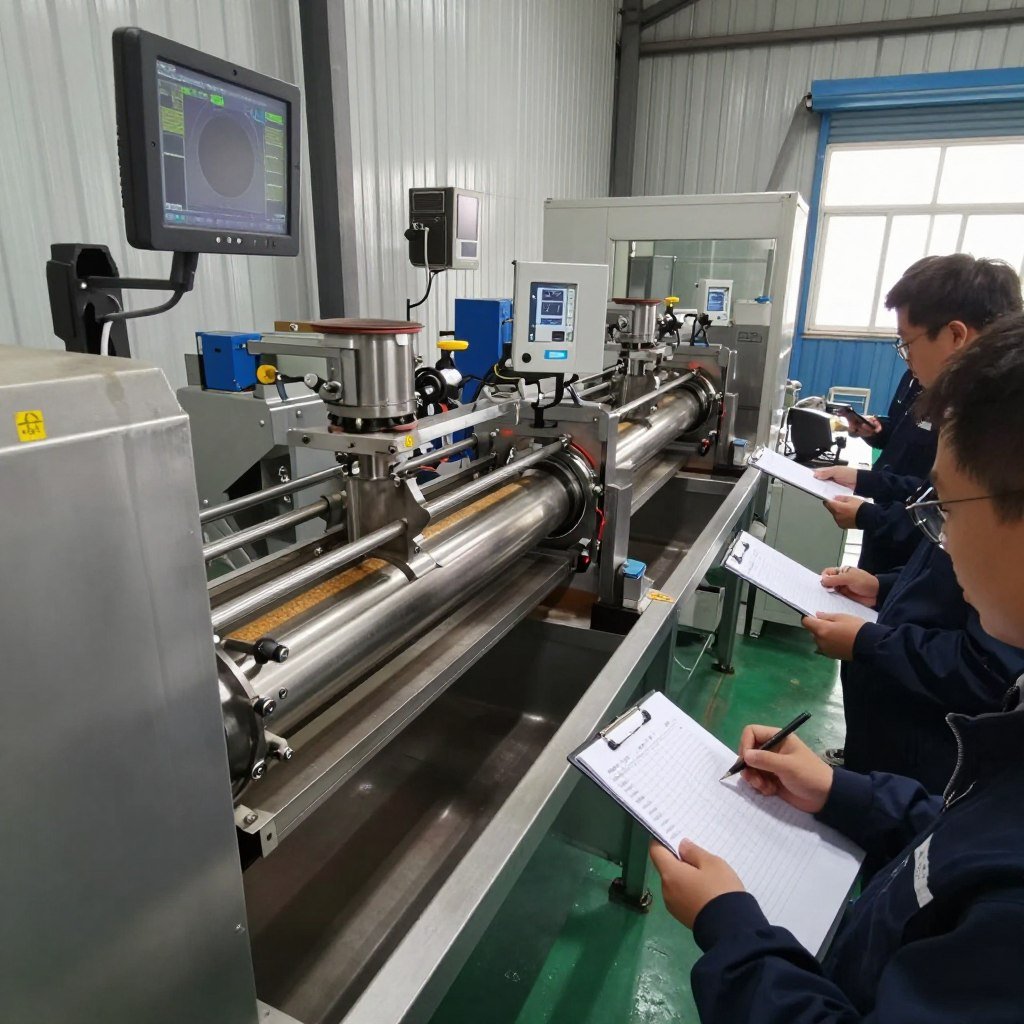

Stage 4: Rigorous Testing and Quality Assurance

Comprehensive performance testing of a completed feed pellet machine

At MAIKONG, we believe that thorough testing is essential to delivering reliable animal feed pellet machines. Every machine undergoes a comprehensive testing protocol before receiving approval for shipment.

Our Multi-Stage Testing Protocol

No-Load Testing

Initial testing verifies electrical systems, motor performance, and mechanical operation without material load, ensuring all systems function correctly.

Load Testing

Machines are tested with actual feed materials to verify production capacity, pellet quality, and consistent performance under real operating conditions.

Endurance Testing

Extended operation testing verifies reliability, temperature stability, and consistent performance over time, simulating real-world production environments.

Quality Metrics We Measure

| Test Parameter | Measurement Method | Acceptance Criteria |

| Pellet Production Rate | Timed collection and weighing | ±5% of rated capacity |

| Pellet Quality | Durability testing, moisture analysis | ≥95% durability index |

| Power Consumption | Power analyzer during operation | ±10% of specification |

| Temperature Stability | Thermal imaging during extended operation | ≤65°C at bearing points |

| Noise Level | Decibel measurement at 1m distance | ≤85dB during operation |

Want to see our testing process in action?

Schedule a virtual demonstration with our technical team to see how we ensure quality in every machine.

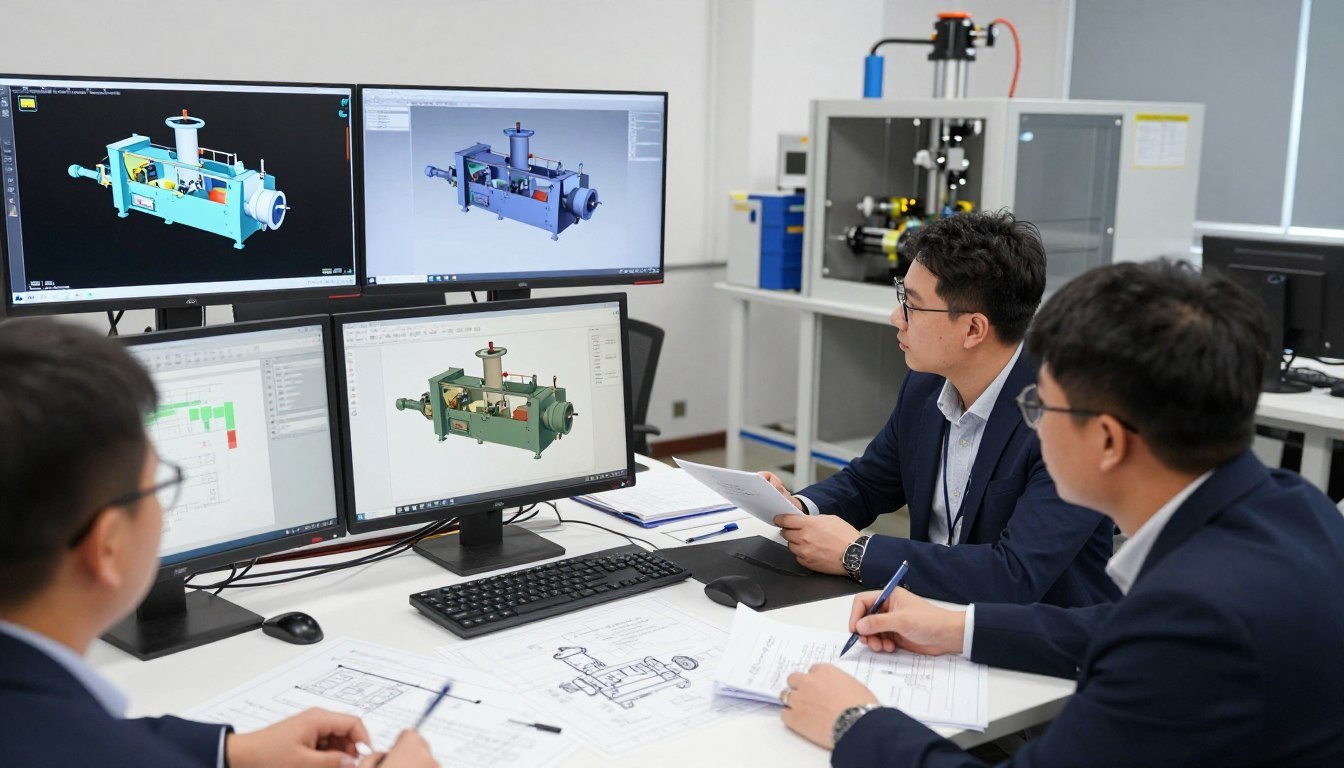

Customization Capabilities for Your Specific Needs

Our engineering team developing custom solutions for specific client requirements

At MAIKONG, we understand that different feed production operations have unique requirements. Our customization capabilities allow us to tailor our animal feed pellet machines to your specific needs.

Machine Customization Options

- Die Configuration: Custom die designs for specific feed materials and pellet sizes

- Production Capacity: Scaled solutions from small farm operations to large commercial facilities

- Power Systems: Electric, PTO, or diesel-powered options to suit your infrastructure

- Control Systems: From basic manual controls to advanced automated systems with remote monitoring

- Material Handling: Customized feeding and discharge systems for your facility layout

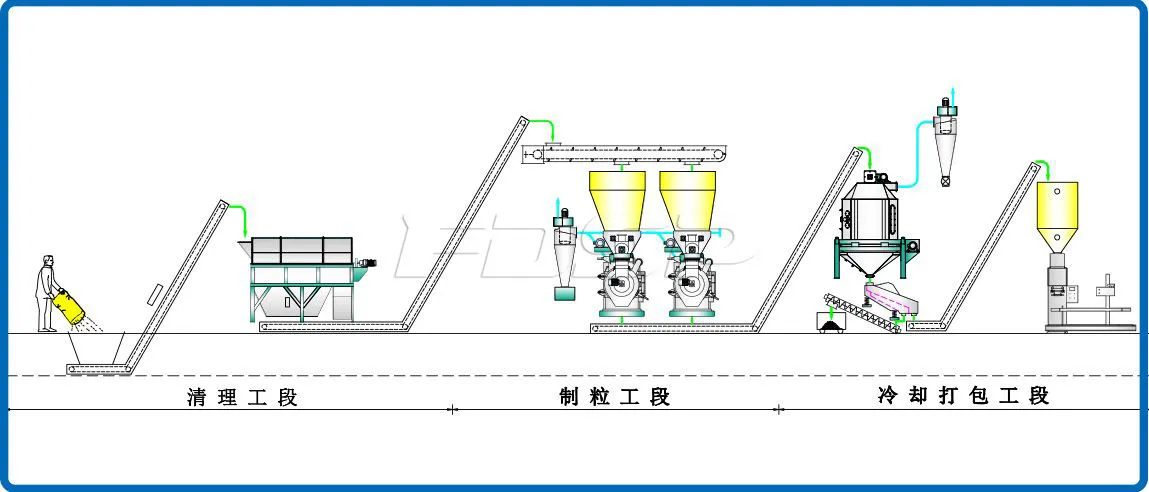

Complete Production Line Integration

Beyond individual machines, MAIKONG designs and manufactures complete feed pellet production lines including:

Complete feed production line designed and manufactured by MAIKONG

- Raw material handling systems

- Grinding and preparation equipment

- Mixing and conditioning systems

- Pelleting machines

- Cooling and drying equipment

- Screening and sorting systems

- Packaging solutions

Our Customization Process

- Consultation: We begin by understanding your specific requirements, materials, and production goals

- Analysis: Our engineering team analyzes your needs and develops customized specifications

- Design: Custom components and systems are designed using advanced CAD technology

- Prototype: For complex customizations, we may develop and test prototype components

- Manufacturing: Custom components are produced using our precision manufacturing processes

- Integration: Custom elements are integrated into your machine or production line

- Testing: Comprehensive testing ensures your custom solution performs to specification

“The MAIKONG team worked closely with us to design a custom feed production line that perfectly matched our unique requirements for processing local materials. Their expertise in customization made all the difference for our operation.”

Need a customized solution for your feed production?

Contact our engineering team to discuss your specific requirements and discover how we can tailor our machines to your needs.

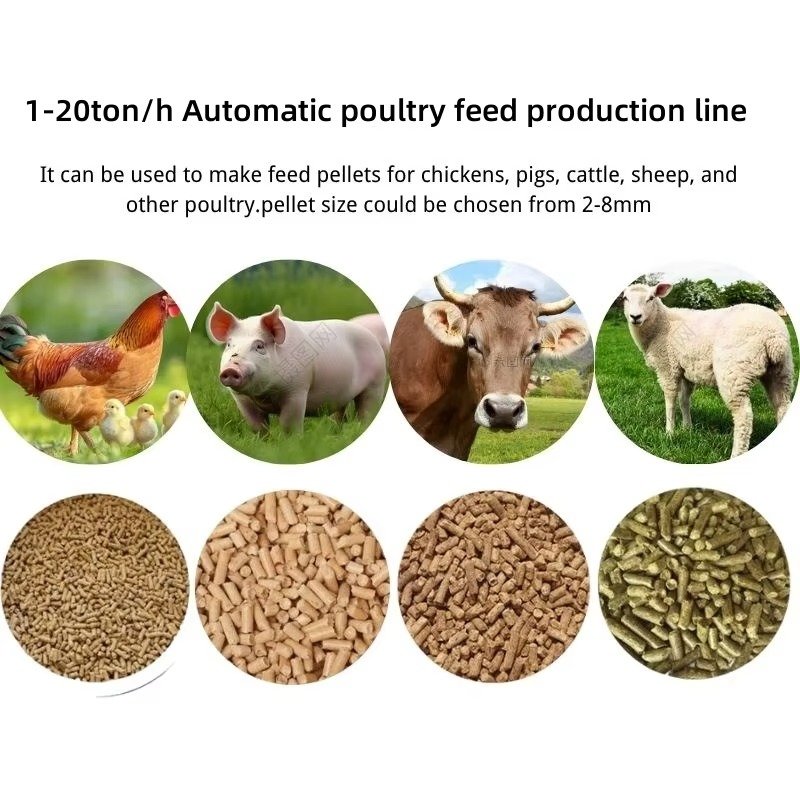

Our Comprehensive Animal Feed Pellet Machine Range

MAIKONG offers a complete range of feed pellet machines and production equipment to meet diverse agricultural needs across South Africa and beyond.

Feed Pellet Machines

- Poultry Feed Pellet Machine

- Cattle Feed Pellet Machine

- Sheep Feed Pellet Machine

- Pig Feed Pellet Machine

- Ruminant Feed Pellet Machine

Biomass Pellet Machines

- Wood Pellet Mill

- Straw Pellet Machine

- Sawdust Pellet Mill

- Alfalfa Pellet Machine

- Grass Pellet Machine

Complete Production Lines

- Poultry Feed Production Line

- Cattle Feed Production Line

- Pig Feed Production Line

- Aqua Feed Production Line

- Fertilizer Production Line

Specialized Solutions

Aqua Feed Solutions

- Floating Fish Feed Machine

- Sinking Fish Feed Machine

- Shrimp Feed Pellet Machine

- Complete Aqua Feed Lines

Fertilizer Granulation Equipment

- Organic Fertilizer Granulators

- NPK Fertilizer Production Lines

- Compound Fertilizer Equipment

- Fertilizer Coating Systems

Comprehensive Support for Your Feed Pellet Production

Our technical support team providing hands-on training and assistance

At MAIKONG, our commitment to your success extends far beyond delivering quality machinery. We provide comprehensive support services to ensure your feed pellet production operates at peak efficiency.

Installation & Commissioning

Our experienced technicians provide professional installation and commissioning services to ensure your equipment is properly set up and optimized for your specific production environment.

- Professional machine setup

- Production line integration

- Initial calibration and optimization

- Operational testing and verification

Training & Knowledge Transfer

We provide comprehensive training for your operators and maintenance personnel, ensuring they have the knowledge and skills to maximize the performance of your animal feed pellet machine.

- Operator training programs

- Maintenance and troubleshooting

- Production optimization techniques

- Safety and best practices

Ongoing Technical Support

Our technical support team is available to assist with any questions or challenges you may encounter, providing prompt, expert guidance to minimize downtime and optimize performance.

- WhatsApp technical assistance

- Remote diagnostics

- Spare parts supply

- Regular maintenance visits

Partnership Opportunities

Distributor & Agent Program

MAIKONG offers attractive partnership opportunities for qualified distributors and agents across Africa. Join our network and represent South Africa’s leading feed pellet machine manufacturer.

Distributor Benefits

- Exclusive territorial rights

- Comprehensive product training

- Marketing and technical support

- Competitive commission structure

- Access to our complete product range

OEM Manufacturing Services

Leverage our 20+ years of manufacturing expertise with our OEM services. We can produce custom-designed feed processing equipment under your brand specifications.

Our OEM manufacturing capabilities for custom-branded equipment

Experience MAIKONG’s exceptional support services

Contact our team today to discuss how we can support your feed production operation or explore partnership opportunities.

Contact MAIKONG – South Africa’s Leading Animal Feed Pellet Machine Manufacturer

Get In Touch

Whether you’re looking for information about our products, need technical support, or want to discuss a custom solution for your feed production needs, our team is ready to assist you.

Email: Lucy@pelletmachine.co.za

Website: https://pelletmachine.co.za/

Online Technical Support

We provide real-time technical support via WhatsApp. For any technical inquiries about your animal feed pellet machine, please add our support WhatsApp: +86 135 1090 7401

Request Information

Experience the MAIKONG Difference in Animal Feed Pellet Machine Manufacturing

For over two decades, MAIKONG has been setting the standard for quality and innovation in feed pellet production equipment across South Africa. Our commitment to engineering excellence, comprehensive support, and customer satisfaction has established us as the trusted partner for agricultural businesses nationwide.

From our meticulous raw material selection to our rigorous testing protocols, every aspect of our manufacturing process is designed to deliver machines that perform reliably in the demanding conditions of African agriculture. Whether you need a standard feed pellet machine or a completely customized production line, MAIKONG has the expertise and capabilities to meet your specific requirements.

Contact us today to discuss how our South African-engineered animal feed pellet machines can enhance your feed production operation and contribute to your business success.

Ready to elevate your feed production capabilities?

Contact MAIKONG today to discuss your specific requirements and discover the perfect solution for your operation.

Contact us online by Whatsapp: