Are rising chicken feed costs cutting into your farm’s profits? MAIKONG’s high-efficiency chicken pellet making machine provides South African poultry farmers with a cost-effective solution for producing premium quality feed pellets on-site. With over 20 years of manufacturing expertise, our machines combine durability, efficiency, and ease of operation to help you take control of your feed production and maximize your returns.

Why Invest in a Chicken Pellet Making Machine for Your Farm

Producing your own chicken feed pellets offers significant advantages for South African poultry operations of all sizes. Our chicken pellet making machine transforms raw materials into nutritionally complete feed pellets that improve chicken health, reduce waste, and substantially cut feeding costs.

Benefits of On-Site Feed Production

- Reduce feed costs by up to 40% compared to commercial feeds

- Control feed quality and nutritional content

- Eliminate supply chain disruptions and price fluctuations

- Create custom formulations for different growth stages

- Improve feed digestibility and reduce waste

- Extend storage life of feed materials

- Increase feed palatability and consumption

Challenges Without Pellet Machines

- Unpredictable commercial feed prices

- Limited control over feed ingredients

- Higher feed waste with unpelletized feed (up to 15%)

- Reduced nutritional consistency

- Difficulty creating specialized formulations

- Dependence on external suppliers

- Higher long-term operational costs

Ready to Reduce Your Feed Costs?

Our experts can help you select the perfect chicken feed pellet machine for your operation’s specific needs.

Contact Our Experts via WhatsApp

MAIKONG: South Africa’s Trusted Feed Pellet Machine Manufacturer

For over two decades, MAIKONG has been at the forefront of pellet machine technology, providing South African farmers with reliable, efficient equipment for feed production. Our commitment to quality and innovation has made us the preferred choice for poultry operations across the country.

MAIKONG chicken feed pellet machine in operation at a South African poultry farm

Our Manufacturing Excellence

- South African-based manufacturing facility

- ISO 9001 certified production processes

- Premium materials for extended durability

- Rigorous quality control standards

- Continuous innovation in pellet technology

Our Customer Commitment

- Dedicated technical support via WhatsApp

- Comprehensive operator training

- Rapid spare parts availability

- Custom machine configurations

- Ongoing maintenance assistance

MAIKONG Chicken Pellet Making Machine Models

We offer a comprehensive range of chicken pellet making machines to suit operations of all sizes, from small family farms to large commercial enterprises. Each model is engineered for reliability, efficiency, and ease of maintenance in South African operating conditions.

| Model |

Power (kW) |

Capacity (kg/h) |

Die Size (mm) |

Dimensions (mm) |

Ideal For |

| MK-150B |

4 |

90-120 |

150 |

800×350×740 |

Small farms (500-1000 birds) |

| MK-200B |

7.5 |

200-300 |

200 |

1050×480×990 |

Medium farms (1000-3000 birds) |

| MK-230B |

11 |

300-400 |

230 |

1180×520×1020 |

Large farms (3000-5000 birds) |

| MK-260B |

15 |

400-600 |

260 |

1240×540×1070 |

Commercial operations (5000+ birds) |

| MK-300B |

22 |

600-800 |

300 |

1300×560×1220 |

Feed suppliers & large operations |

MAIKONG MK-230B model producing uniform chicken feed pellets

Power Options for South African Conditions

Understanding South Africa’s unique power challenges, MAIKONG offers multiple power configurations for our chicken pellet making machines:

Electric Models

Standard three-phase electric motors optimized for efficiency and South African power specifications.

Diesel Engine Models

Ideal for areas with unreliable electricity supply or remote locations without grid access.

PTO Models

Connect directly to your farm tractor’s power take-off for maximum versatility and mobility.

Need Technical Specifications?

Our engineering team can provide detailed technical information and help you select the right power option for your location.

Request Technical Consultation

Advanced Features of MAIKONG Chicken Feed Pellet Machines

Our chicken pellet making machines incorporate innovative design elements that ensure superior performance, longevity, and ease of maintenance in demanding South African farming environments.

Precision-engineered components ensure reliable operation and long service life

Structural Excellence

- Premium Alloy Dies: Heat-treated for extended wear resistance and consistent pellet formation

- Sealed Bearing Design: Prevents contamination and lubricant leakage for longer service intervals

- Precision CNC Manufacturing: Ensures perfect alignment of all components for reduced vibration and noise

- Reinforced Frame Construction: Withstands continuous operation in demanding environments

Operational Advantages

- Hypoid Gear Transmission: Delivers higher efficiency and smoother power transfer

- Adjustable Roller Pressure: Optimizes performance for different feed materials

- Quick-Change Die System: Minimizes downtime when switching between pellet sizes

- Integrated Safety Features: Protects operators and prevents equipment damage

Pellet Size Options

MAIKONG machines can produce chicken feed pellets in multiple diameters to suit different poultry ages and types:

MAIKONG machines produce uniform pellets in sizes ranging from 2mm to 8mm

| Pellet Size |

Recommended For |

| 2-3mm |

Chicks and young broilers |

| 4-5mm |

Growing broilers and layers |

| 6-8mm |

Adult chickens and breeders |

Optimizing Chicken Feed Production with MAIKONG Machines

Creating high-quality chicken feed pellets involves more than just the right equipment. Our experts provide comprehensive guidance on feed formulation, raw material selection, and production processes to maximize the benefits of your MAIKONG chicken pellet making machine.

Recommended Raw Materials for Chicken Feed

Quality raw materials ensure nutritionally complete chicken feed pellets

Grains & Carbohydrates

- Maize/Corn

- Wheat

- Barley

- Sorghum

- Oats

Protein Sources

- Soybean Meal

- Sunflower Meal

- Fish Meal

- Lucerne/Alfalfa

- Canola Meal

Additives

- Vitamin Premix

- Mineral Supplements

- Calcium Sources

- Binding Agents

- Probiotics

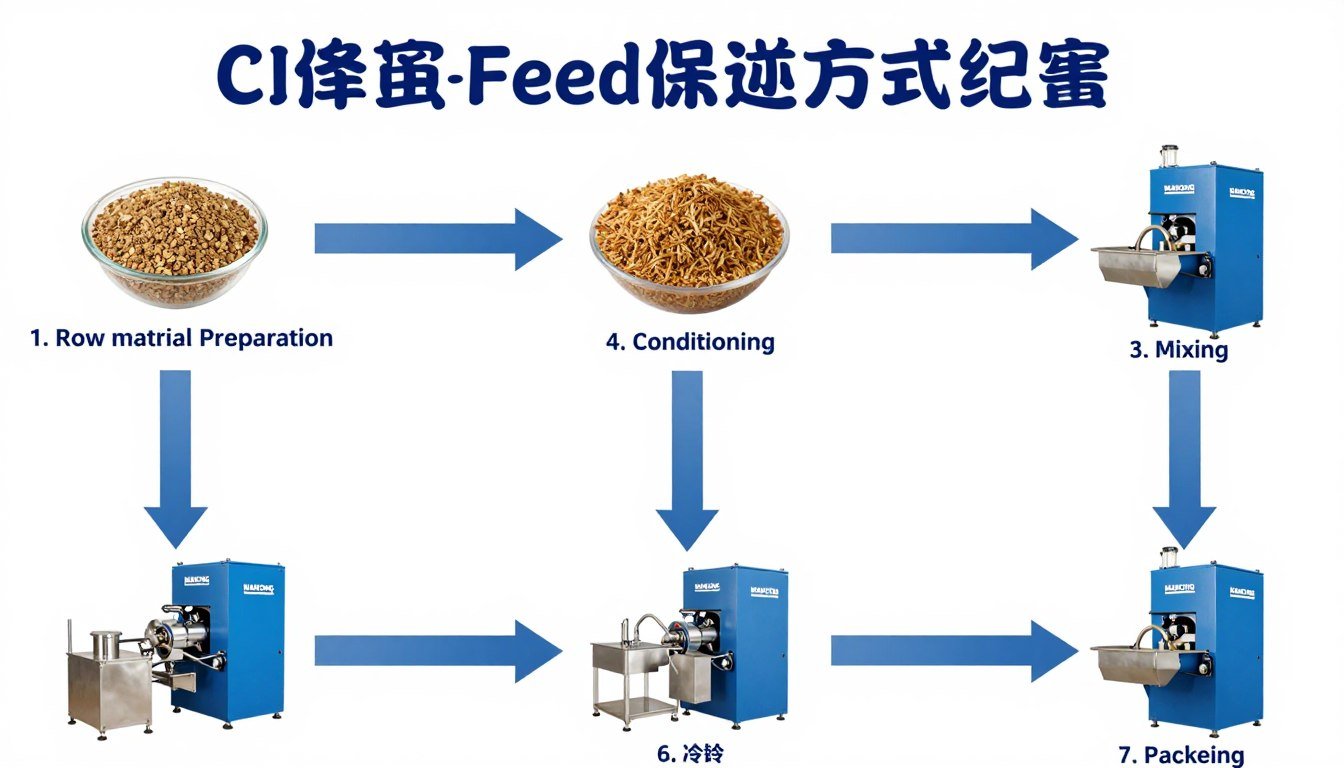

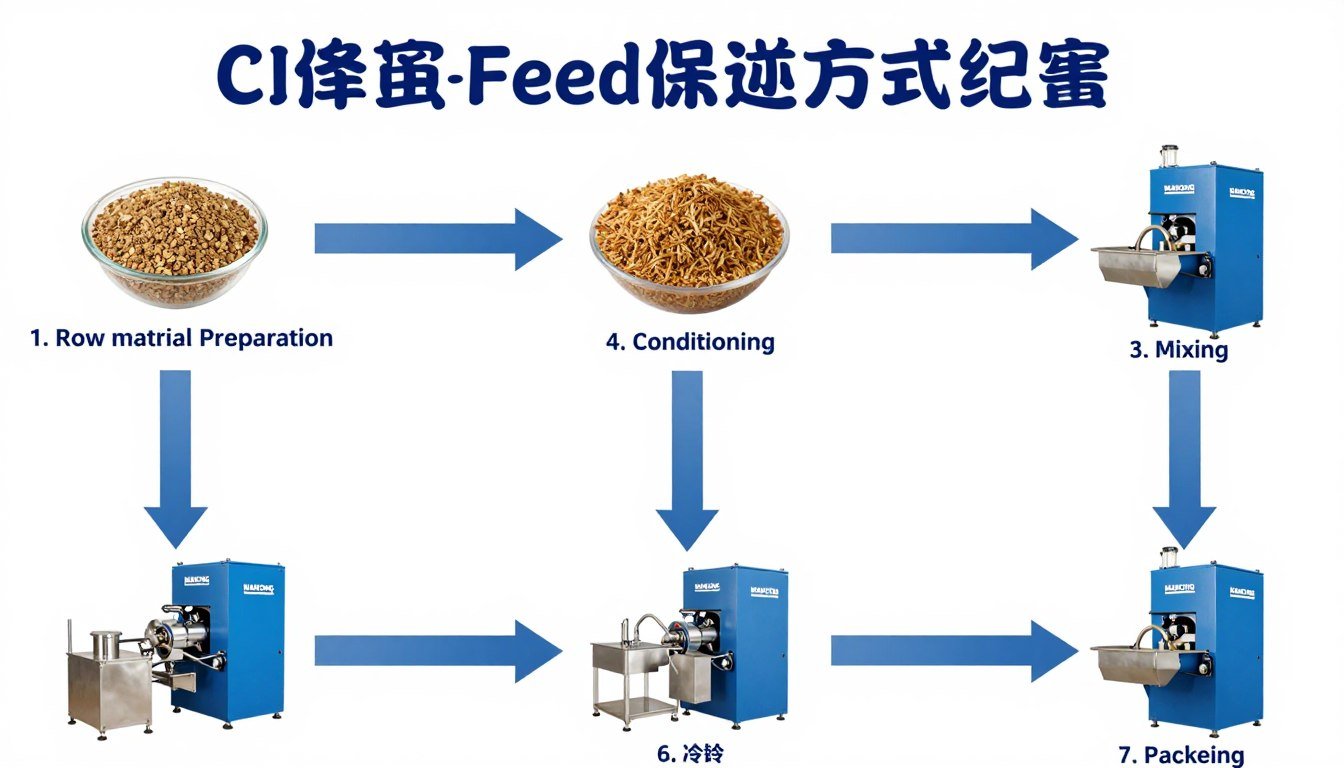

Basic Chicken Feed Pellet Production Process

Complete feed pellet production workflow with MAIKONG equipment

- Raw Material Preparation: Clean and sort ingredients to remove contaminants

- Grinding: Process materials to uniform particle size using MAIKONG hammer mills

- Mixing: Combine ingredients according to formulation in MAIKONG feed mixers

- Conditioning: Add moisture and heat to improve binding properties

- Pelletizing: Compress the mixture through the die of your MAIKONG chicken pellet making machine

- Cooling: Reduce pellet temperature and moisture content for storage stability

- Packaging: Store in appropriate containers to maintain freshness

Need Help With Feed Formulations?

Our poultry nutrition specialists can provide customized feed formulations optimized for your specific chicken breed and production goals.

Get Expert Advice via WhatsApp

Customized Solutions for South African Poultry Farms

At MAIKONG, we understand that every poultry operation has unique requirements. Our chicken pellet making machines can be customized to meet your specific needs, ensuring optimal performance and return on investment.

MAIKONG’s technical team customizing equipment for specific client requirements

Customization Options

Machine Customization

- Custom die configurations for specific pellet requirements

- Alternative power systems (electric, diesel, PTO)

- Enhanced capacity modifications

- Special corrosion-resistant components for coastal areas

- Integration with existing farm equipment

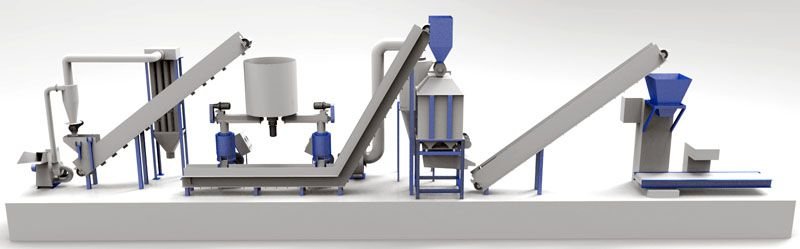

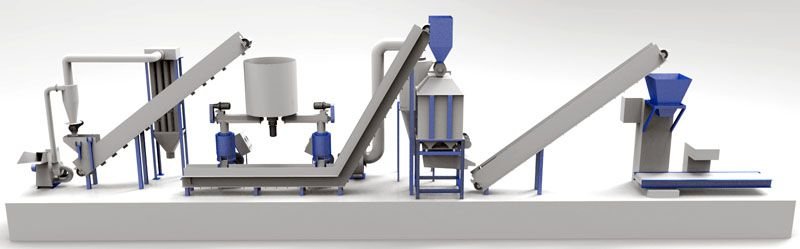

Production Line Customization

- Complete feed production line design

- Space-optimized layouts for limited facilities

- Automated control systems

- Custom feed storage solutions

- Specialized material handling equipment

“MAIKONG worked closely with us to design a custom feed production system that perfectly fits our farm’s requirements. Their attention to detail and understanding of South African farming conditions made all the difference.”

– Johan Pretorius, Poultry Farm Owner, Western Cape

Discuss Your Custom Requirements

Our engineering team can develop tailored solutions for your specific operation and space constraints.

Contact Our Design Team

Comprehensive Support for South African Customers

MAIKONG provides exceptional support throughout your journey – from initial inquiry to installation, training, and ongoing maintenance of your chicken pellet making machine.

MAIKONG provides comprehensive training for all machine operators

Pre-Purchase Support

- Detailed technical consultations

- Site assessment services

- Production capacity planning

- ROI and cost analysis

- Custom solution development

Implementation Support

- Professional installation services

- Comprehensive operator training

- Feed formulation guidance

- Production process optimization

- Quality control procedures

Ongoing Support

- Rapid WhatsApp technical assistance

- Preventive maintenance programs

- Genuine spare parts supply

- Software updates for automated systems

- Production efficiency audits

WhatsApp Technical Support

MAIKONG offers immediate technical assistance via WhatsApp. Our support team is available to help with troubleshooting, maintenance advice, and operational questions.

Technical Support WhatsApp: +86 135 1090 7401

MAIKONG maintains comprehensive spare parts inventory for all machine models

Business Opportunities with MAIKONG

Beyond providing top-quality chicken pellet making machines, MAIKONG offers various business partnership opportunities for South African entrepreneurs and existing agricultural businesses.

Become a Distributor

Join our network of authorized MAIKONG equipment distributors in South Africa. We provide comprehensive training, marketing support, and competitive commission structures.

OEM Manufacturing

MAIKONG offers OEM manufacturing services for businesses looking to develop their own branded feed processing equipment. Leverage our 20+ years of manufacturing expertise.

Feed Production Business

Start your own commercial feed production business with MAIKONG equipment. We provide complete business setup guidance, from equipment selection to market development.

Explore Business Opportunities

Contact our business development team to discuss partnership opportunities with MAIKONG.

Discuss Partnership Options

Frequently Asked Questions About Chicken Pellet Making Machines

What raw materials can be used in MAIKONG chicken pellet making machines?

MAIKONG chicken pellet making machines can process a wide variety of raw materials including corn, wheat, barley, soybean meal, sunflower meal, fish meal, bone meal, vitamins, minerals, and various agricultural by-products. The machines are designed to handle both dry and slightly moistened materials with proper conditioning.

How much electricity does a chicken pellet making machine consume?

Power consumption varies by model and production volume. Our smaller MK-150B (4kW) typically consumes about 3-3.5 kWh during operation, while larger models like the MK-300B (22kW) may consume 18-20 kWh at full capacity. For areas with unreliable electricity, we offer diesel-powered and PTO-driven alternatives.

What is the return on investment period for a chicken pellet making machine?

Most South African poultry farmers report ROI periods of 8-18 months, depending on operation size, feed volume, and local commercial feed prices. Farms producing 500+ kg of feed daily typically see faster returns. Our team can provide a customized ROI analysis based on your specific operation parameters.

Does MAIKONG provide installation and training services?

Yes, MAIKONG provides comprehensive installation, commissioning, and operator training services throughout South Africa. Our technical team ensures your equipment is properly installed and your staff is fully trained on operation, maintenance, and troubleshooting procedures. We also offer ongoing support via WhatsApp for immediate assistance.

Can MAIKONG machines produce pellets for other animals besides chickens?

Absolutely! While marketed as chicken pellet making machines, our equipment is versatile and can produce feed pellets for various livestock including cattle, sheep, goats, pigs, fish, and other poultry. Different die sizes and configurations are available to accommodate specific requirements for each animal type.

Take Control of Your Chicken Feed Production Today

Investing in a MAIKONG chicken pellet making machine is more than just purchasing equipment – it’s a strategic decision to improve your farm’s efficiency, reduce costs, and enhance feed quality. With over 20 years of manufacturing experience, MAIKONG provides South African poultry farmers with reliable, efficient, and customizable feed production solutions.

Join hundreds of satisfied MAIKONG customers across South Africa

Ready to Transform Your Feed Production?

Contact MAIKONG today to discuss your chicken feed pellet production needs and receive a customized solution proposal.

Or call us directly: +86 135 1090 7401