South Africa Top pellet machine, animal feed pellet machine Manufacturer

The Importance of Spare Parts Availability for Your Animal Feed Pellet Machine in ZA

February 5, 2026

The Real Cost of Animal Feed Pellet Machine Downtime in South Africa

When your animal feed pellet machine stops working, the consequences extend far beyond the immediate inconvenience. For South African agricultural operations, equipment failure creates a devastating chain reaction:

Immediate Financial Losses

- Daily production losses averaging R5,000-R15,000 for small operations

- Raw material spoilage due to interrupted processing

- Labor costs continuing despite halted production

- Emergency repair premiums (up to 200% higher than planned maintenance)

Long-term Business Impact

- Compromised livestock health due to inconsistent feeding

- Damaged client relationships from missed deliveries

- Market share loss to more reliable competitors

- Increased total cost of ownership over equipment lifespan

“In our experience working with South African farmers, a single day of downtime for an animal feed pellet machine can cost a medium-sized operation between R8,000-R20,000 in direct losses. The indirect costs to your reputation and customer relationships are immeasurable.”

Common Failure Points in Feed Pellet Machines

Understanding the typical wear components in your animal feed pellet machine helps you anticipate maintenance needs and maintain optimal performance. Based on MAIKONG’s 20+ years of manufacturing experience, these are the components that require the most frequent replacement:

| Component | Function | Typical Lifespan | Impact of Failure | Availability Importance |

| Die Rings | Forms pellets by compressing feed through holes | 300-800 hours depending on material | Complete production stoppage | Critical |

| Roller Assemblies | Presses feed material against die | 500-1000 hours | Reduced capacity, poor pellet quality | Critical |

| Bearings | Supports rotating components | 1000-2000 hours | Mechanical damage, production stoppage | High |

| Drive Belts | Transfers power from motor to mechanism | 1500-3000 hours | Immediate production halt | High |

| Conditioner Paddles | Mixes steam with feed materials | 2000-4000 hours | Poor pellet quality, reduced durability | Medium |

| Knives/Cutters | Cuts pellets to desired length | 300-600 hours | Inconsistent pellet length, blockages | Medium |

Important Note for South African Operators: Local environmental factors like dust, humidity, and variable raw material quality can significantly reduce component lifespan compared to manufacturer estimates. Always maintain a comprehensive spare parts inventory for your specific animal feed pellet machine model.

The MAIKONG Advantage: Unmatched Spare Parts Support

With over two decades of experience manufacturing premium animal feed pellet machines, MAIKONG has developed a spare parts support system specifically designed for the South African market. Our approach eliminates the common frustrations experienced with other equipment suppliers:

The MAIKONG Difference

- Comprehensive Local Inventory: We maintain extensive spare parts stocks in South Africa for immediate availability

- Guaranteed Authenticity: All parts are manufactured to exact OEM specifications

- Rapid Delivery: Emergency parts delivery within 24-48 hours across South Africa

- Extended Availability: We guarantee parts availability for 10+ years for all machine models

- Technical Documentation: Detailed maintenance guides and parts diagrams included with every machine

Common Industry Problems

- Extended Downtime: Weeks or months waiting for imported parts

- Counterfeit Concerns: Substandard non-OEM parts causing further damage

- Obsolescence Risk: Discontinued support for older models

- Communication Barriers: Difficulty reaching overseas technical support

- Hidden Costs: Unexpected import duties and emergency shipping fees

Never Risk Production Downtime Again

Speak with our spare parts specialists today to understand how MAIKONG’s comprehensive support system can protect your feed production operation.

Preventive Maintenance: Maximizing Your Animal Feed Pellet Machine Lifespan

A strategic preventive maintenance program is essential for maximizing the operational lifespan of your animal feed pellet machine. MAIKONG’s technical team has developed this comprehensive maintenance schedule based on our experience with South African operating conditions:

| Maintenance Interval | Required Actions | Recommended Spare Parts | Benefit |

| Daily |

|

None | Early problem detection, prevents major failures |

| Weekly |

|

Lubricants | Extends component life, maintains efficiency |

| Monthly |

|

Gearbox oil, safety switches | Prevents contamination, ensures safety compliance |

| Quarterly |

|

Die rings, rollers, bearings | Maintains optimal production capacity and pellet quality |

| Annually |

|

Complete maintenance kit | Extends machine lifespan, prevents major failures |

MAIKONG Maintenance Advantage: Every animal feed pellet machine we supply comes with a comprehensive maintenance manual customized for South African operating conditions. Our technical team also provides free online training for your maintenance staff.

Customized Solutions for South African Feed Production

MAIKONG understands that South African feed production operations face unique challenges. Our animal feed pellet machines can be customized to your specific requirements, ensuring optimal performance and minimizing maintenance issues:

Climate Adaptations

- Enhanced dust protection systems

- High-temperature operation modifications

- Humidity-resistant electrical components

- Corrosion-resistant materials for coastal areas

Material Processing

- Specialized dies for indigenous feed materials

- Adjustable compression ratios

- Custom roller configurations

- Variable speed drives for different materials

Production Requirements

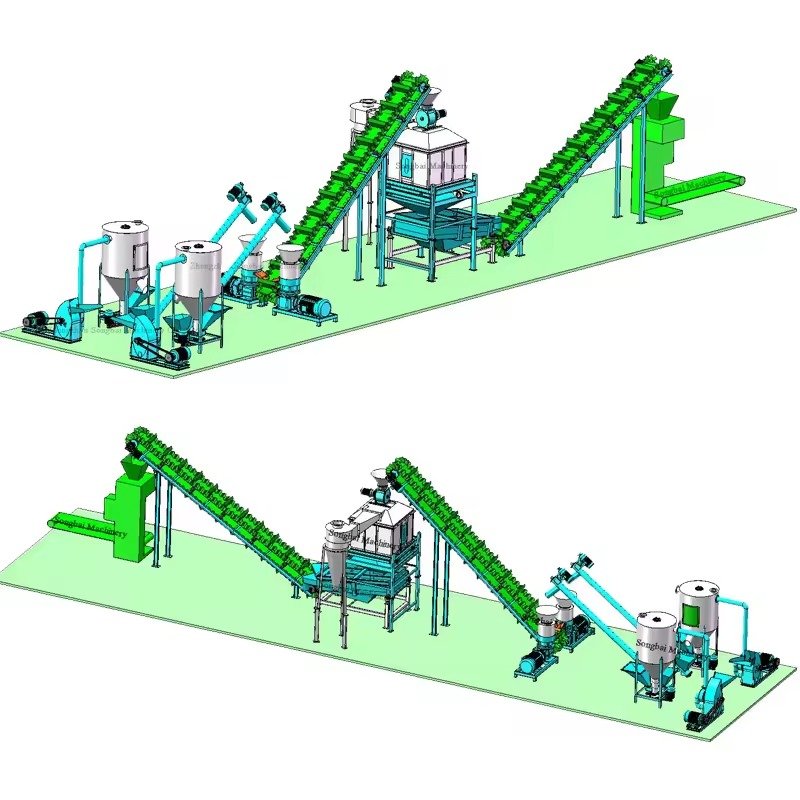

- Scalable capacity options (50kg/h to 3000kg/h)

- Integration with existing production lines

- Custom pellet sizes and shapes

- Energy efficiency optimizations

“We’ve been using MAIKONG’s customized animal feed pellet machine for processing our unique blend of indigenous grasses and supplements. Their understanding of our specific needs and ongoing spare parts support has been invaluable to our operation.”

Get Your Custom-Designed Feed Pellet Solution

Our engineering team will analyze your specific requirements and develop a customized animal feed pellet machine solution with comprehensive spare parts support.

Technical Specifications: MAIKONG Animal Feed Pellet Machine Range

MAIKONG offers a comprehensive range of animal feed pellet machines to meet the diverse needs of South African agricultural operations. All models are designed for durability, efficiency, and ease of maintenance:

| Model | Capacity (kg/h) | Power (kW) | Die Size (mm) | Pellet Diameter (mm) | Dimensions (m) | Key Features |

| MK-125 | 50-100 | 3 | 125 | 2-8 | 0.7×0.4×0.8 | Compact design, single-phase option |

| MK-150 | 100-150 | 4 | 150 | 2-10 | 0.8×0.5×0.9 | Enhanced durability, easy maintenance |

| MK-230 | 300-500 | 11 | 230 | 2-12 | 1.2×0.7×1.1 | Dual-stage processing, auto-lubrication |

| MK-300 | 800-1000 | 22 | 300 | 2-15 | 1.4×0.9×1.3 | Industrial-grade, continuous operation |

| MK-400 | 1000-1500 | 30 | 400 | 2-20 | 1.7×1.0×1.5 | Advanced control system, multi-material |

| MK-500 | 2000-3000 | 55 | 500 | 2-25 | 2.0×1.2×1.8 | Full production line integration, remote monitoring |

Important Selection Advice: When choosing an animal feed pellet machine, consider not just your current production needs but your future growth plans. Upgrading to a larger capacity machine later often costs significantly more than initially investing in a model with room for production expansion.

Comprehensive After-Sales Support

MAIKONG’s commitment to your operational success extends far beyond the initial purchase of your animal feed pellet machine. Our comprehensive support services ensure you receive maximum value from your investment:

Installation & Training

- Professional installation by certified technicians

- Comprehensive operator training

- Maintenance staff certification

- Customized production optimization

Technical Support

- 24/7 WhatsApp technical assistance

- Remote diagnostics capabilities

- Emergency on-site service

- Regular software updates

Maintenance Programs

- Scheduled maintenance contracts

- Preventive parts replacement

- Performance optimization

- Extended warranty options

How quickly can MAIKONG deliver spare parts to South African customers?

MAIKONG maintains an extensive inventory of spare parts in our South African distribution center. For common wear components, we offer same-day or next-day delivery to most locations. For specialized components, our maximum delivery time is 3-5 business days—significantly faster than the industry standard of 2-4 weeks for imported parts.

Does MAIKONG provide technical support in multiple languages?

Yes, our technical support team provides assistance in English, Afrikaans, and Zulu to ensure clear communication with all South African customers. Our support documentation is also available in these languages.

Can MAIKONG integrate spare parts management with our existing maintenance system?

Absolutely. MAIKONG offers integration with common maintenance management systems. We can also provide a customized spare parts inventory management solution that tracks usage patterns and automatically suggests reordering based on your specific animal feed pellet machine model and production volume.

Experience Unmatched Technical Support

Our technical specialists are available 24/7 to answer your questions and provide immediate assistance for your animal feed pellet machine.

Contact MAIKONG: Your Trusted Partner in Feed Production

With over 20 years of experience in designing and manufacturing premium animal feed pellet machines, MAIKONG has established itself as South Africa’s most reliable partner for feed production equipment. Our commitment to comprehensive spare parts availability and exceptional technical support ensures your operation maintains maximum productivity.

Why Choose MAIKONG

- 20+ Years Experience: Decades of R&D and manufacturing expertise

- Comprehensive Product Range: From small farm units to industrial production lines

- South African Focus: Products designed specifically for local conditions and materials

- Guaranteed Parts Availability: Extensive local inventory of all critical components

- Customization Capabilities: Tailored solutions for your specific requirements

- Ongoing Technical Support: 24/7 assistance via multiple channels

Get In Touch

Our team is ready to assist you with any questions about our animal feed pellet machines, spare parts availability, or customization options.

Contact Information

- Email: Lucy@pelletmachine.co.za

- Phone/WhatsApp: +86 135 1090 7401

- Website: https://pelletmachine.co.za/

Online Technical Support: We use WhatsApp for immediate technical assistance. If you have any technical questions about your animal feed pellet machine, add our support WhatsApp: +86 135 1090 7401

Conclusion: Invest in Reliability with MAIKONG

When investing in an animal feed pellet machine for your South African operation, the availability of spare parts should be a primary consideration—not an afterthought. MAIKONG’s commitment to comprehensive spare parts availability, rapid delivery, and expert technical support ensures your production remains consistent and profitable throughout your equipment’s lifespan.

With over two decades of experience serving the South African agricultural sector, MAIKONG understands the unique challenges you face. Our complete range of animal feed pellet machines, customization capabilities, and unmatched after-sales support make us the partner of choice for operations that cannot afford downtime.

Contact our team today to discuss your specific requirements and discover how MAIKONG’s comprehensive spare parts program can protect your investment and maximize your operational efficiency.

Ready to Eliminate Downtime Concerns?

Speak with our specialists about your animal feed pellet machine requirements and learn how our comprehensive spare parts program can safeguard your production.

Contact us online by Whatsapp: